Polystyrene balls! The damn things get everywhere! ![]()

As hoped I've managed to make a start on the embankment that runs along the Northern side of the running lines. The basic shape for this has been made from Foam Board in order to keep the weight down, and then wedges of polystyrene cut to shape and glued into the gaps. A thin layer of a PVA/polyfiller mix was then spread on top and this will be lightly sanded before being painted.

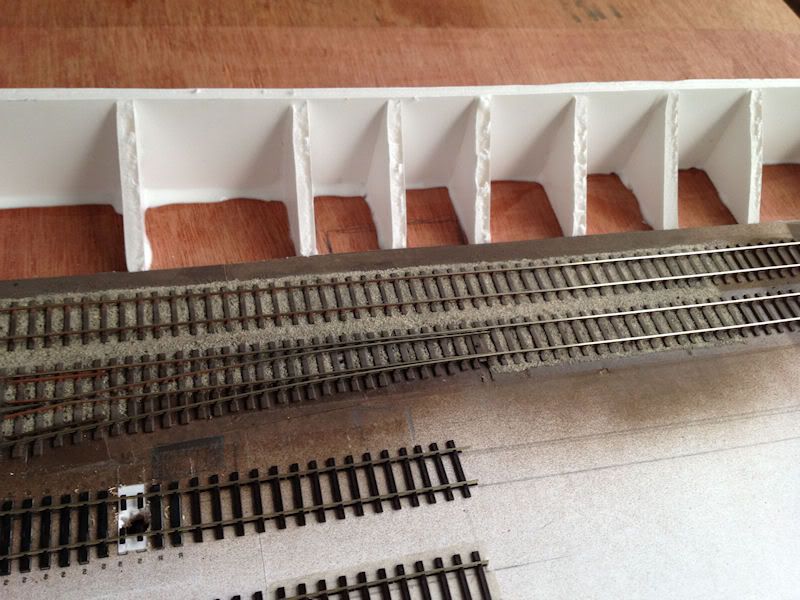

Here's the basic construction taking place:

The polystyrene foam wedges in place (post vacuuming!):

And the current state of play, with a top layer now drying out:

The rest of the embankment will be formed once the backscene is fitted, and I'm still contemplating how best to do this, so more on that another time!

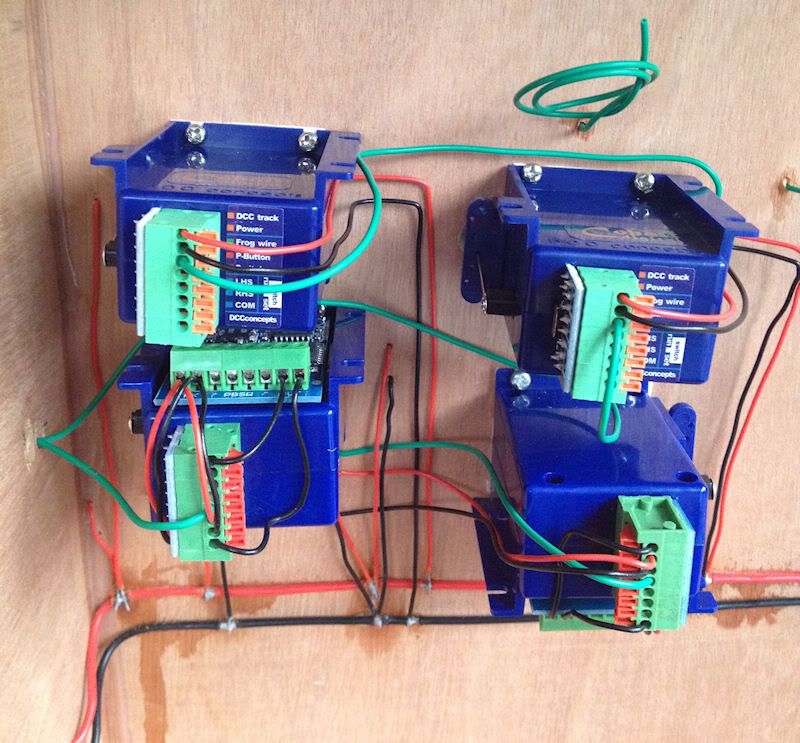

I've also managed to fit the 2 Cobalt point motors picked up at Warley, so the Barry slip is now fully operational! I am glad I went with the Cobalt motors. It's quite cosy under the main point formations, and tortoises wouldn't have fitted into the available space:

Just a warning, electronics experts should look away now.........

The two new motors are at the top, and you can see that only 3 wires are needed to get a fully operational motor. The green wires run to the frogs, and the black and red wires to the main bus. That said, even the older motors with the AD1 decoders don't require that much wiring!

I should really crack on and finish the one remaining point that can be seen in the photos above, so that will be the next job I think.

Cheers all!

Tom.

-

1

1

7 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now