So what size are yours - flagstones?

The list of jobs to do is endless but finishing off the platforms must come near the top.

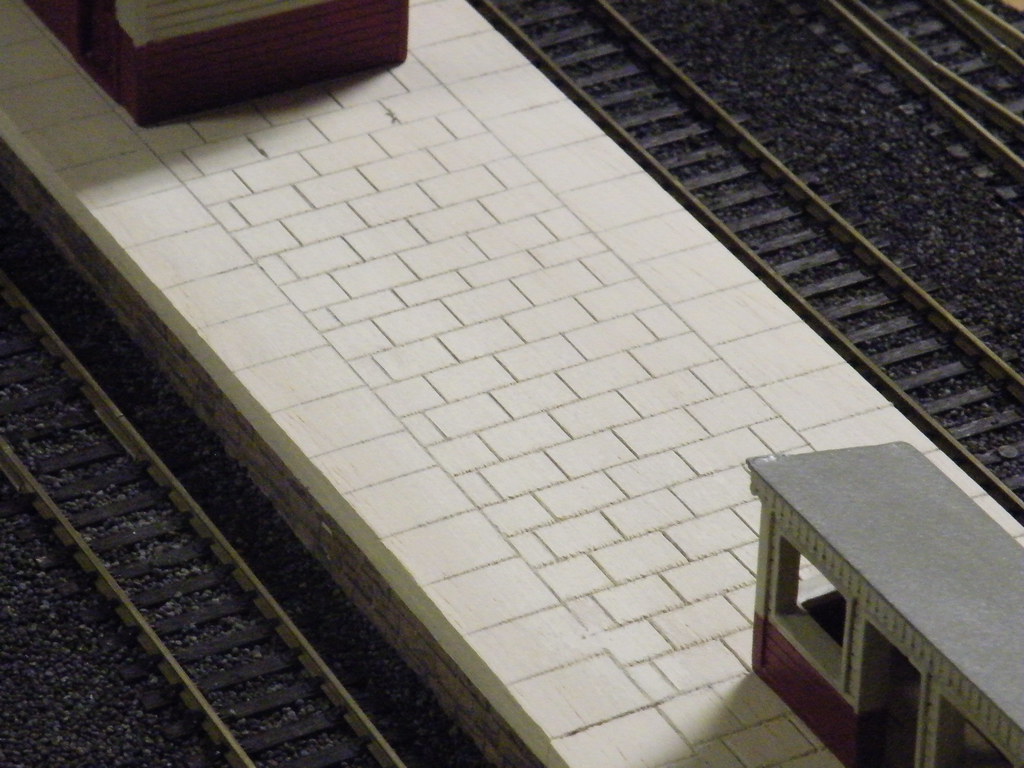

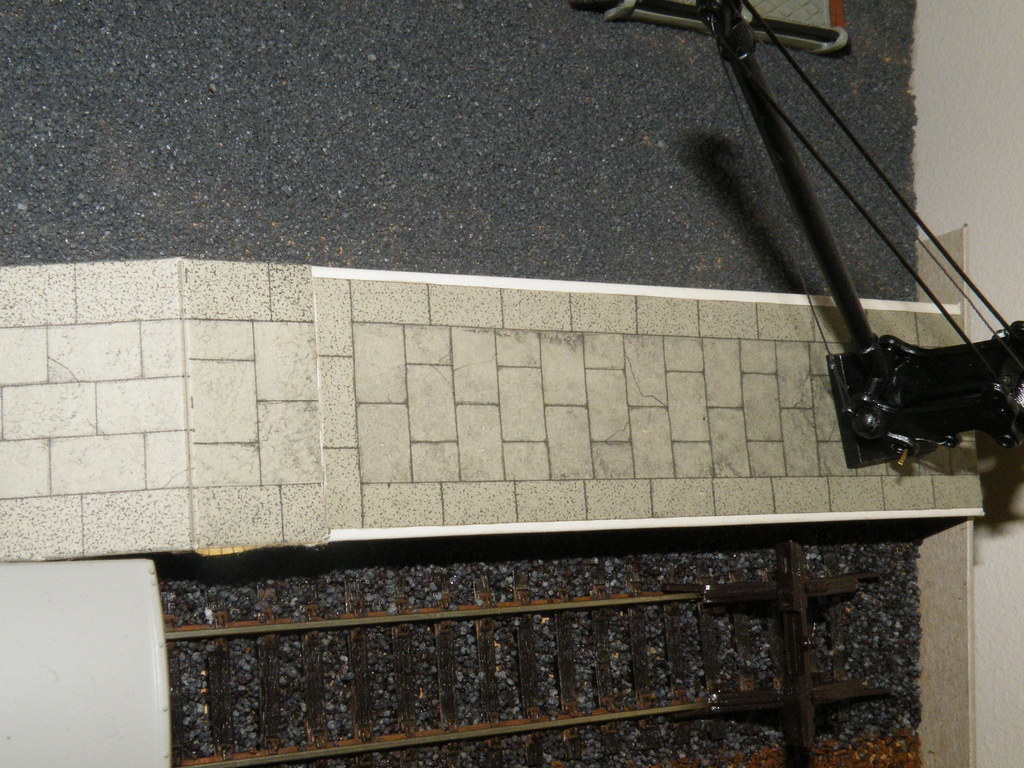

This could be quite a long task but first what size to make the paving? The British Standard suggests that paving stones should preferably be 900 x 600, 750 x 600 or 600 x 600 (mm). However my layout represents the late 1950s, early 1960s, long before metrication. In those days, and for some considerable time after, the standard size of paving stone was 3ft x 2ft equivalent to 12mm x 8mm in 00 scale. Perhaps not surprisingly this is the size modeled by Superquick for their station platforms.

However the 3ft x 2ft pressed concrete slab is relatively modern and a lot of railway platforms constructed in the 1800s will have used natural stone, probably York Stone in the north of England or maybe Purbeck or Cotswold stone in the south of England. The decision to standardize on 3ft x 2ft for the new concrete paving seems to be based upon the commonly available sizes of natural stone which in turn is likely to have been related to the maximum size and weight of material that could easily be handled manually.

A search online indicates that natural stone paving is currently available in a range of sizes with widths up to 3ft. It would also appear that in addition to the standard 3ft x 2ft size, a larger 4ft x 2 ft slab is offered, perhaps as used above historically at Chester General Station?

So much for what is currently available but what was used in the past? I guess those of you in the more populous parts of the UK will have the option to go and measure up some real station platforms. However for those others like myself, living in more distant and rural parts, this luxury is not available and it is back to searching through pictures in old books. The picture of Holywell above is good example of the type of view available and shows different patterns of paving for different areas of the platform.

In addition to printed pictures there are vast numbers of images available on line. One of the most readily available sources must be that of the Flickr web site. The 'screen shot' above shows just one page of views obtained by typing 'Ramsbottom Railway Station' into the Flickr search bar. Just type in your favourite location and see what is available.

In due course I will have to mark out my chosen patterns of paving. This is likely to be a long and tedious process. Not surprisingly the view above of Coldstream station is one of my favourites. I like precedents and if you get tired of marking out individual flagstones, well how about using some cast in situ concrete.

I also like the above view of Barnard Castle Station. I think the modern Codes of Practice recommend that the platform slopes back down from the platform edge to prevent prams and platform trolleys accidentally rolling on to the track in front of trains. None of this in the view above. The platform surface obviously falls down to the platform edge to allow easy drainage of rain water. I seem to recollect that in those days each platform trolley was equipped with a cast iron 'wedge' attached by chain for chocking one of the trolley wheels. I guess also that in those days no one ever left their pram unattended?

To be continued.

-

2

2

-

2

2

.thumb.jpg.60c53fcbcaa34017b05b8919d1a9e6d2.jpg)

16 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now