Mega-Trabbi: Gützold's rendition of Mitteldeutsche Eisenbahn's class 156 electric

And hello again!

The following article had been in preparation for a while, but it has only been this past October that I managed to track down the actual model I was intending to present. With Gützold currently being in liquidation but still looking for new ownership (last time I checked, anyway), their excellent H0 scale models are currently becoming rarities, so I was all the more glad when I was able to find the Mitteldeutsche Eisenbahn variant of their class 156 electric in a sale. This model was marketed with catalogue number 43300 and represented a special release of Gützold's 156, which had first been released in DB Cargo and Deutsche Reichsbahn variants from 2001 onwards.

In any case, I won't bother you with a very long preface, and instead turn to the heart of the matter!

Background information

In general terms, the German Democratic Republic‘s Deutsche Reichsbahn was initially slow in adopting electric traction on their network, which in 1979 comprised a total length of 14,164 kilometres, of which only 1,621 were electrified. This, of course, also had much to do both with post-war reparations which had resulted in significant lengths of overhead lines and associated equipment in the Soviet zone having been dismantled, and numerous electric locos from the pre-1945 Reichsbahn having been shipped to the Soviet Union along with it. However, much of this equipment was returned in the early 50s in an effort to stabilise the GDR economy, resulting in electric operations recommencing in 1955.

In addition, economic obligations for the entire East Bloc set by the COMECON resulted in GDR locomotive builders having to concentrate on manufacturing diesel locomotives. Also, the fact of the GDR having access to cheap oil from the Soviet Union contributed to Deutsche Reichsbahn preferring diesel locomotives – and, to some degree, oil-fired steam engines – till the second oil crisis of 1979 affected the Warsaw Pact states. As a result of the latter, railway electrification was again prioritised by the early 80s, obviously also generating a large demand for suitable electric locomotives to augment the fleet of pre-war class 204 (E 04), 218 (E 18), 244 (E 44) and 254 (E 94) locos, as well as the GDR-designed class 211 and 242 Bo‘Bo‘ and 250 Co‘Co‘ locomotives. In addition, a replacement for the class 251 Co‘Co‘ electrics used only on the 25 kV AC Rübeland Railway and derived from the 211/242 family was also considered desirable.

It was at this time that the extremely successful class 243 Bo‘Bo‘ electrics were first introduced, of which 646 locos were built between 1984 and 1991, and which also continue to form an important part of Deutsche Bahn‘s loco fleet till this day – now of course designated class 143.

With train weights continuing to increase during the 80s, the older 211s and 242s in particular often needed to be set up in multiples, which eventually was recognised as an argument for another Co‘Co‘ configured type to augment the 243s and 250s. In addition, negotiations concerning an upgrade of the Hanover-Berlin mainline for a top speed of 160 kph and including electrification to improve route capacity for transit workings from West Germany to Berlin were ongoing at the time, also making an evolved twelve-wheel loco derived from the 243 a sensible proposition.

In the final years of the GDR, Deutsche Reichsbahn eventually ordered an initial batch of four Co‘Co‘ prototypes, which were built by the LEW works at Hennigsdorf and designated class 252. On 10 March 1991, 252 004 was transferred to the Leipzig Spring Fair for an official presentation, with the remaining three locos also being rolled out over the following months. The four 252s then underwent route trials which were conducted mostly between Halle and Berlin, and culminated in 252 002 being provisionally approved for scheduled service in late November that year, which also allowed driver training to commence. In March 1992, the 252s were assigned to Dresden‘s Friedrichstadt depot, which would turn out to remain their home during their years in Deutsche Bahn service. Also in 1992, all DR classes were redesignated according to DB AG standards, with the 252s now being known as class 156.

In 1994, newly formed Deutsche Bahn eventually decided against procuring additional 156s in favour of an additional lot of class 112 Bo‘Bo‘ express locos, which had been easily derived from the 143 and required no additional trials, allowing quick production to provide urgently needed passenger locos for newly created IC and IR services to the Eastern states. Eventually, the 70 orders for additional class 156 locos were cancelled, both due to three-phase AC locos having been generally favoured at the time and a significant downturn in freight traffic following German unification.

The four 156s continued to work from Dresden, and were mainly used for freight workings, though their turns also included a small number of passenger workings, which included InterRegio services on the Leipzig-Hof Railway with its maximum gradient of 1%. In 1998, they were allocated to DB Cargo, which was how DB AG‘s freight sector was called at the time. Due to their small number and only few drivers having been rated on them, the 156s but were likely candidates for an early withdrawal from service. However, they were granted one additional full revision. In 2002, DB Cargo considered assigning these locos to banking duty on the Leipzig-Hof mainline, but when trials revealed them to not be particularly well suited for this kind of service they were quickly earmarked for withdrawal by the end of the year. When this happened, they were put in conserved storage, so as to hopefully be sold to other operators.

In late 2003, private freight operator Mitteldeutsche Eisenbahn (MEG), in which Deutsche Bahn are holding a majority of shares, agreed to purchase all four 156s. After receiving revisions to remove idle time damage, they were designated as locomotives 801 through 804, and had all re-entered revenue service till November 2004. They are now commonly found on various freight workings, some of which also see them to destinations in the Western states.

Design

As previously mentioned, the 156 was largely derived from the class 243 electrics, and thus shares numerous design features and components with this class. However, it is also a somewhat more distant relative of the 155, a description of which you can find in this blog entry I wrote up earlier: The East is Red

The two six-wheel bogies feature a welded steel frame, with the wheelsets being held in roller bearings, which in turn are suspended from lemniscate levers. The middle wheelsets on 156 001 have their flanges thinned by 10 mm for better curve running, while no lateral displacement was provided on any of the wheelsets, but would have been likely to have been on the production locos if procurement had not been cancelled. The primary suspension stage consists of four helical springs per wheelset plus vertically mounted hydraulic motion dampers.

Braking gear on this class comprises multiple-lapping unified Knorr type pneumatic tread brakes with direct and indirect controls and a mechanical parking brake function, with the pneumatic brakes being blended with the rheostatic brake.

The 156‘s body is an all-welded lightweight steel design whose overall outline is slightly resembling that of the West German class 120 Bo‘Bo‘ locomotives, which were developed roughly during the same period as the 156. Much like on the 143, it consists of a welded steel frame with two longitudinal main beams and six transversal beams, the outermost of which also serving as bufferbeams. The second pair of transversal beams is located above the bogies and carries the pivot pins, while the remaining beams – as well as the set of auxiliary strengthening beams – serve to reinforce the engine room floor for the weight of the transformer. The body‘s layout is again largely similar to that of the 143, with the cabs being separate subassemblies and the roof being divided into three sections which can be independently removed for internal maintenance and removal of large components. Ventilation grilles for the traction motor and engine room blowers are set in the pitched lateral roof planes. Unlike the 143, the 156‘s body sides are not corrugated, however.

The cab layout is closely related to that of the 143 in order to allow for easy cross-training of drivers. Consequently, the 156 is also equipped with the sophisticated speed control function of the 143, which largely automates power control by allowing the driver to set targets for speed and tractive effort, with both the tap changer and dynamic brake then being governed as required to match the selected speed and maximise adhesion at the same time. In addition to this standard programme acting both on the tap changer and dynamic brake, four special modes are available for a variety of route and timetable profiles:

-

„Freier Auslauf“ (roughly: „Free Power-Down“) can be triggered to manually set the tap changer to idle, with the automatic brake governor also being disabled so as to allow the loco to coast with neither power nor dynamic brake force applied.

-

„Bedingter Auslauf“ („Conditional Power-Down“) is intended for maximising acceleration for tight timetable situations or short distances between stations. To this end, the tap changer will remain powering up till just short of the selected target speed, after which the controls will automatically switch to „Freier Auslauf.“ In this mode, the wheelslip control circuit will allow a greater percentage of „creep“ as well to maximise adhesion by way of allowing the tap changer to shift up to two notches higher at any point during the acceleration phase than in normal mode. Consequently, it is recommended for the driver to manually order a power-down ahead of time by way of the provided „Delete“ key as required because the loco might else exceed the selected speed.

-

„Nur Fahren“ („Power only“) is intended for uphill gradients, and has the controls disregard the dynamic brake altogether. In other words, using this mode, speed is regulated only by powering up and down, relying on gravity and friction to slow the train as required rather than engaging the dynamic brake, for which purpose the tap changer must have shifted down to idle, usually leading to an unnecessarily large speed loss due to the time required to run down to idle and power up anew.

-

„Nur Bremsen“ („Braking only“) is the opposite to „Nur Fahren“ and is intended for longer downhill gradients, preventing the tap changer from powering up, with speed being regulated only through the dynamic brake.

Like the 143, the 156 also has air-conditioned cabs, which was far from being the norm on German motive power – West or East – of the 1980s.

While there are a few small differences, the general outline of the 156's cab looks like this:

Photo by Wikipedia user "Trappi", published and permitted for re-use under the Creative Commons CC-by-sa 3.0 licence.

The large black handle to the left of the driver is the speed/power selector assembly, with which the traction control programme switches are co-located. The TFT screen immediately beyond the power controller is for the electronic working timetable – abbreviated "EBuLa" – to the right of which there is a combined instrument cluster with the tractive/braking effort gauge on the left, and the speedometer on the right. The indicator lamps below these two gauges are mainly related to the Indusi train protection system – especially the three blue lights and the white, red and yellow indicators below. The two gauges to the right are the brake pressure indicators, while the array of switches at the driver's right includes the vigilance, release and manual override triggers for the Indusi, as well as those for the circuit breaker, pantographs, blowers and compressor. The brake controllers are set to the right of the driver as well, with the larger valve below being for indirect brake controls and the smaller valve with the green body for the direct shunting brake.

Locomotive controls are based on an adapted version of the proven logic board setup from the 143 on 156 001, 002 and 004, whereas 156 003 is equipped with a microprocessor-based SIBAS 16 computer suite from Siemens, featuring one primary and one backup computer. As a result, status monitor screens are available in the cabs of 156 003. On all locos, the logic board arrays or onboard computers are located on the inner bulkhead of Cab 1. Finally, all locomotives are equipped with a PZB train protection suite and radio. Additionally, 156 001, 002 and 004 were refitted with a TDM-based MU control package from 2007 onwards, which allows these locos to work in multiple with all class 112, 114 and 143 locomotives – with their current operator MEG also having a number of 143s in their inventory. Consequently, these three 156s are frequently seen paired with one of those 143s on certain heavy workings.

The transformer is a three-core oil-cooled design with split primary and secondary stage, with each half supplying one of the bogies to help limit current draw. It is connected to a 31-notch thyristor-assisted tap changer which allows for almost stepless power control, and also has separate taps for auxiliary circuits and ETS. Meanwhile, the traction motors are a slightly augmented version of those used on the 143, providing a one-hour output of 980 kW per motor instead of 930.

Auxiliary systems, such as motor blowers, compressor and others, are fed from a 380 V/50 Hz three-phase grid, which in turn is supplied by a motor-driven rotating inverter on 156 001, and by a static inverter consisting of a common rectifier with DC link and four secondary side inverter modules on 156 002 through 004. As a result of this setup, the auxiliary grid is split into four groups on these three locos for greater redundancy.

And this would bring us to the photo strip for this model...

Gützold's 156/252 was highly praised when it was first released, and to my mind still is a very fine rendition of this locomotive which in reality had turned out to be among the oddballs of German motive power. Tests conducted at the time of the original release proved it to be highly accurate in scale, and due to a well-thought-out chassis design and significant weight offer excellent tractive power. On the very first production batch of the DB Cargo variant, however, the mouldings for the body sides had been accidentally exchanged, which but was quickly remedied.

The model #43300 represents 156 001 in its current guise of Mitteldeutsche Eisenbahn, with the company's internal running number 801. This loco has the LEW works number 20004.

As this side view of the Cab 1 end will hopefully reveal, the model's paintwork and lettering is impeccable, too. As per the inscriptions above the bogie, 156 001 had had her last revision completed at the Dessau works (abbreviated LDX) on 28 June 2007.

The braking weights are also called out, being 135 tonnes on "R", 115 tonnes on "P" and 90 tonnes on "G", with the loco's service weight being indicated as 120 tonnes.

As you can also see, the 156's wheelsets are asymmetrically spaced, much like on the 155.

In general terms, MEG's current livery with white frontside warning panels could be said to resemble the final livery 252 002 had carried in the last years of Deutsche Reichsbahn, as this, too, included a white frontside warning panel. Note how the head and tail lights are stacked rather than arranged horizontally on the left and right of the body faces.

On the rooftop, it is noticeable how Gützold chose to obtain the same miniatures of the trademark VSH 2F2 pantographs Roco use on their class 143/243 electric, which was praised in reviews as contributing to a plausibly uniform appearance when operating Deutsche Reichsbahn motive power. Also note the rectangular access hatches in the cab roofs and the round rooftop hatch next to the rheostatic braking tower towards the Cab 2 end. On German electrics, it has long been common practice to locate the circuit breaker towards Cab 1, while the device next to the #2 pantograph is the OHLE voltage sensor.

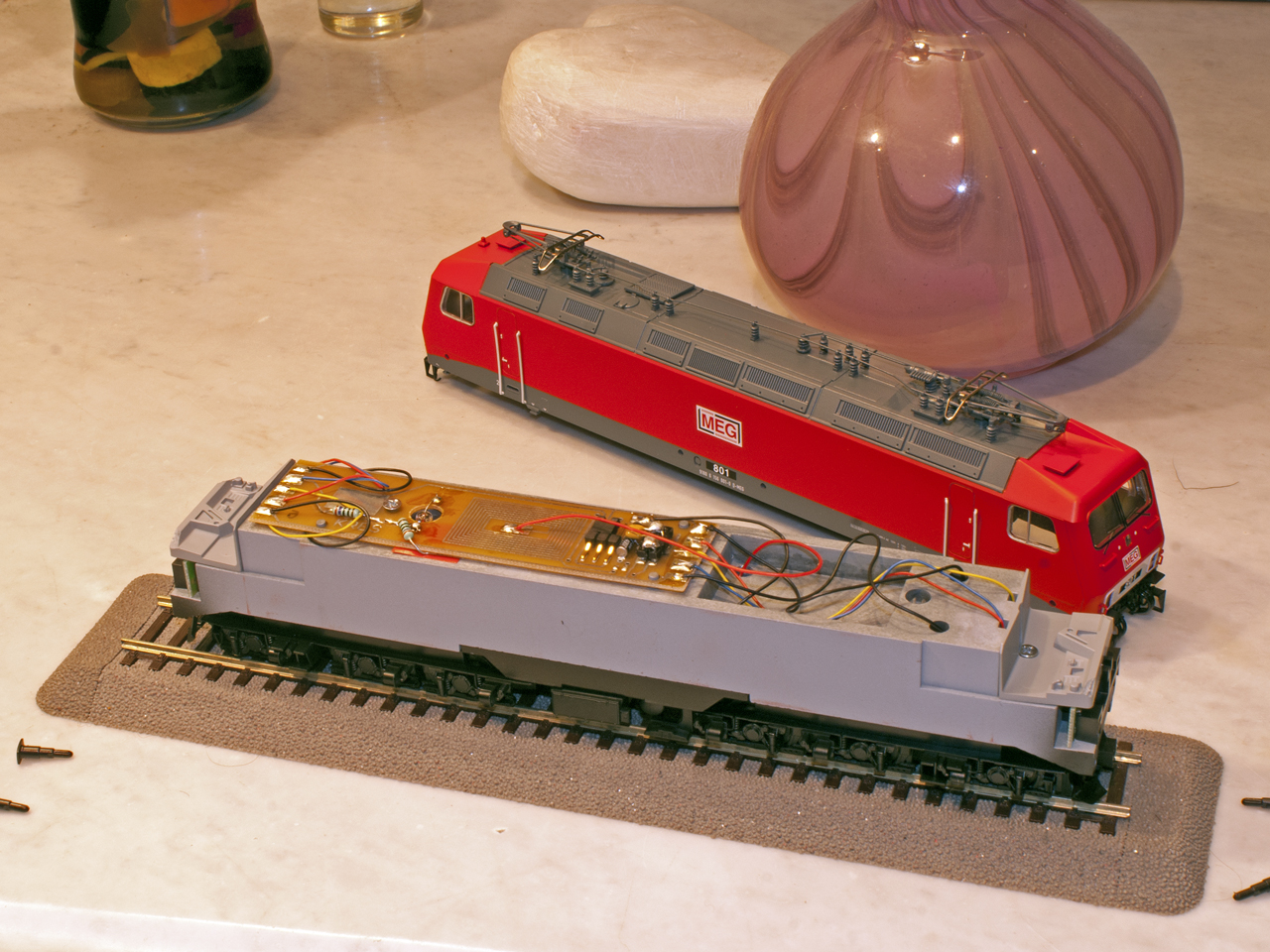

And to round off this loco portrait, I was thinking that you might be interested in seeing the loco's interior. To take off the body, you need to remove the buffers, after which just a touch of spreading the body sides is required to lift it off the chassis. As you can see, the frame is a massive cast metal piece, resulting in the model weighing in at about 680 grams, or about 1.5 lbs. It is lighted by LED boards set below the cab interior pieces, with plastic chutes sealing the headlight and tail light chambers. There also is sufficient space for a DCC decoder, which goes into the recess on the Cab 1 end of the metal frame. The motor, of course, is located below the main PCB.

Edit – 8 November: Turns out I forgot the technical specs for the 156, so here goes...

Overall length – 19.50 m/64 ft

Overall width – 3.1 m/10.2 ft

Overall height – 4.65 m/15.3 ft

Wheel diameter – 1.25 m/4.1 ft new, 1.16 m/3.8 ft maximum wear

Service weight – 120 tonnes/118 long tons

Power output – 5,880 kW one-hour rating, 5,580 kW continuous

Initial tractive effort – 361 kN/81,156 lbf

Maximum speed – 125 kph/77 mph

Once again – thank you for your time and I hope you enjoyed this article! ![]()

-

3

3

2 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now