Track-laying progress

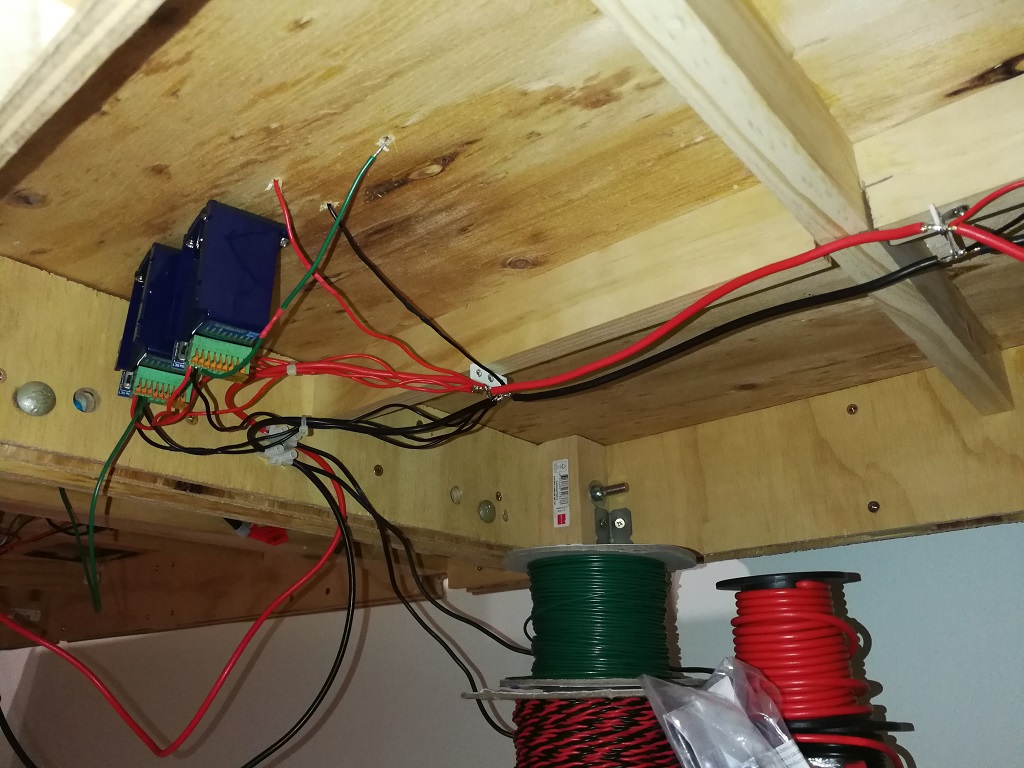

Big day yesterday, nice to have the time off work. Amazing how time consuming it is though, especially when you are putting droppers on every piece of track... I Installed 2 x sets of points (both of which have had the ugly Peco mechanisms cleaned out and new sleepers soldered in), a diamond, track to the future turntable, and the catch point behind the diamond (also tidied up); and setup the wiring and DCC Concepts Cobalt Digital IP motors driving them.

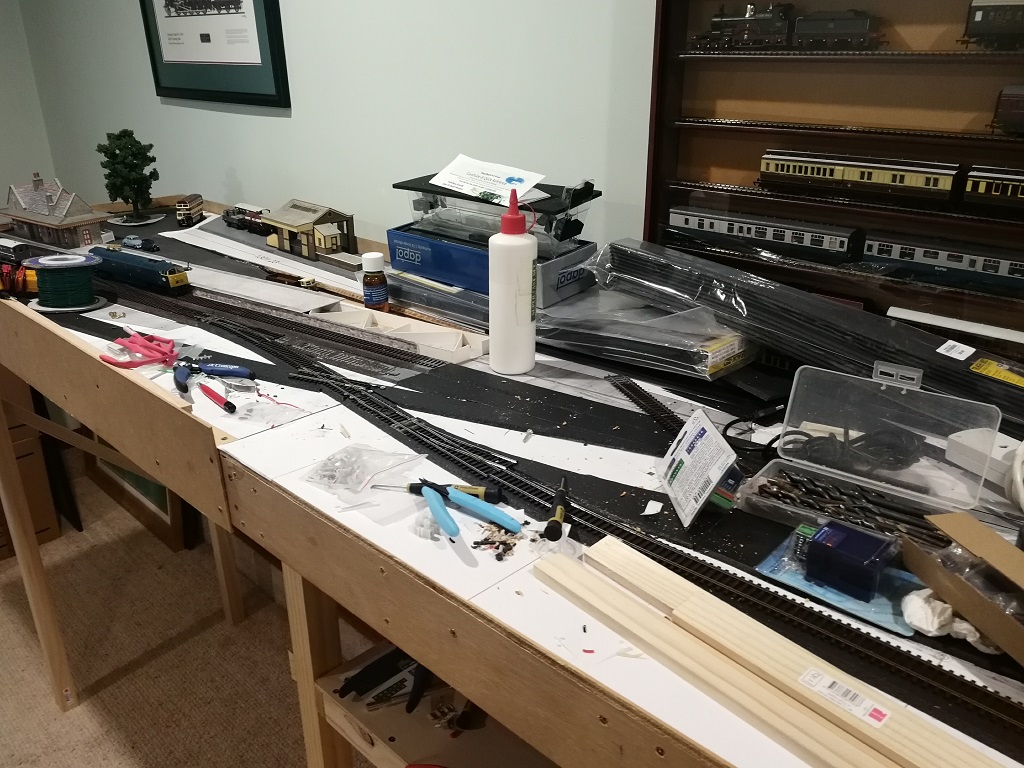

Middle of the day:

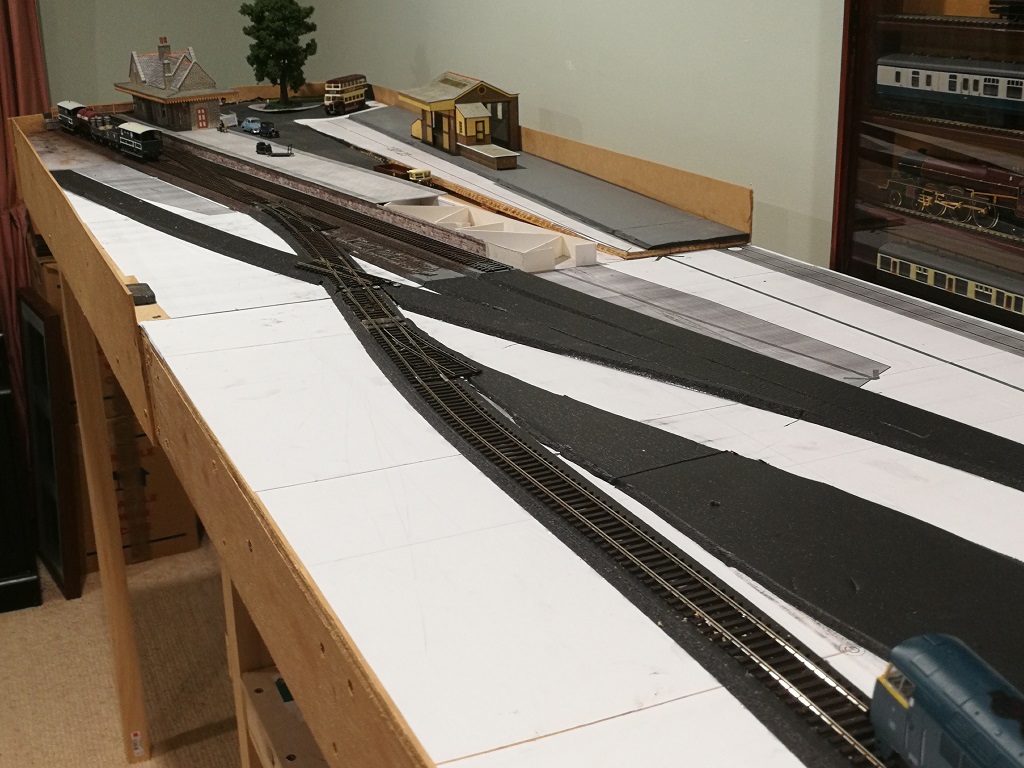

End of the day:

The tracks either side of the baseboard join in the middle are soldered to stainless steel screw heads at the correct height, which holds height and position perfectly. No close-up pictures there yet - I'll need to do some camouflage to make them look a little less obvious.

The points / catch point either side of the diamond are controlled via the same DCC address as a pair, and drive the diamond's frogs' polarity. All working a treat, very happy.

Underneath, Cobalt Digital IPs in place and working beautifully:

-

4

4

1 Comment

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now