Flight of the bumblebee

I’m building a traverser of sorts for the fiddle yard of my little goods depot layout. From an engineering perspective it’s a bit dodgy - yet somehow it works, so I’ve dubbed it the bumblebee.

I’m building a traverser of sorts for the fiddle yard of my little goods depot layout. From an engineering perspective it’s a bit dodgy - yet somehow it works, so I’ve dubbed it the bumblebee.

My original plan was to have a fiddle yard with points, but as space is becoming an issue I decided to go for a traverser instead. Trouble is, my engineering skills are equal to those of the common earthworm.

So I’ve been putting it off, until I came across some bits and pieces in the local DIY and acted on impulse. What has developed is best seen as an experiment!

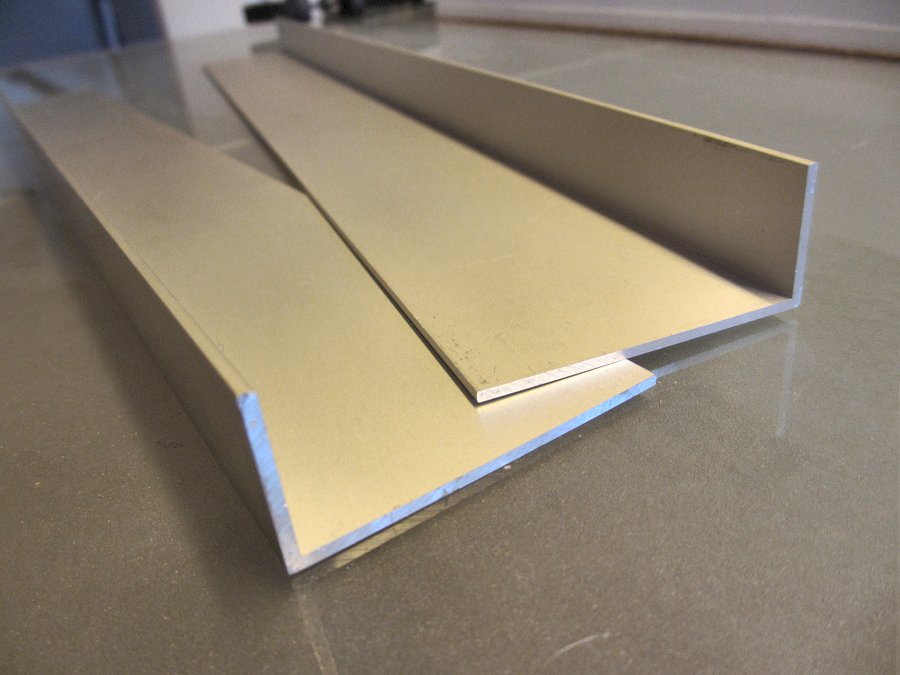

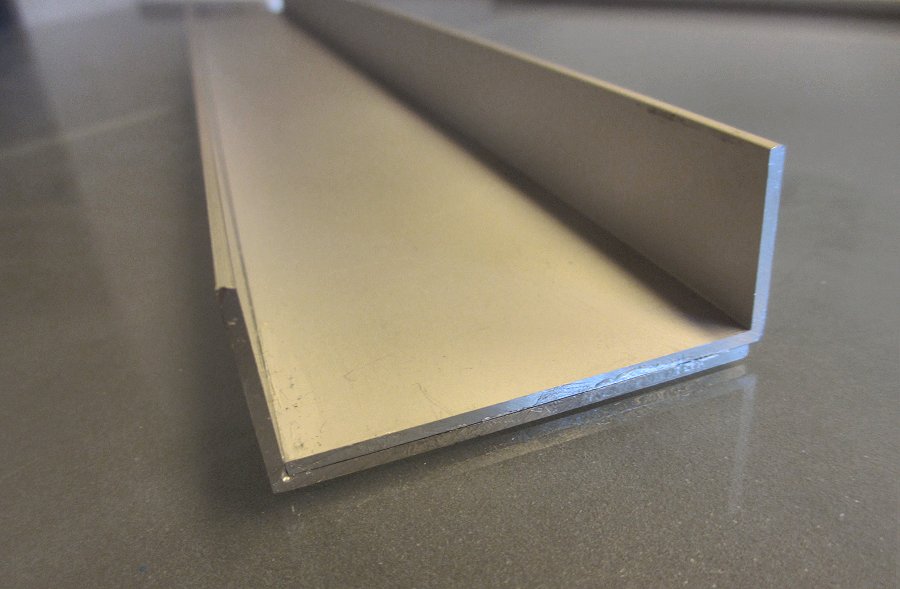

Two aluminimum angles from the local DIY.

Cobbled together, they make up a sturdy cassette.

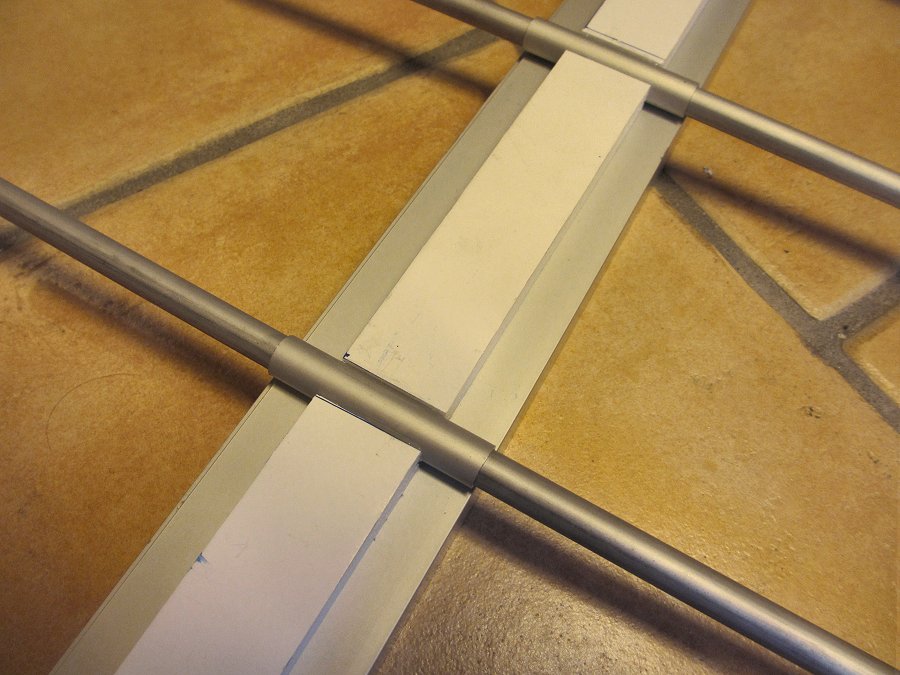

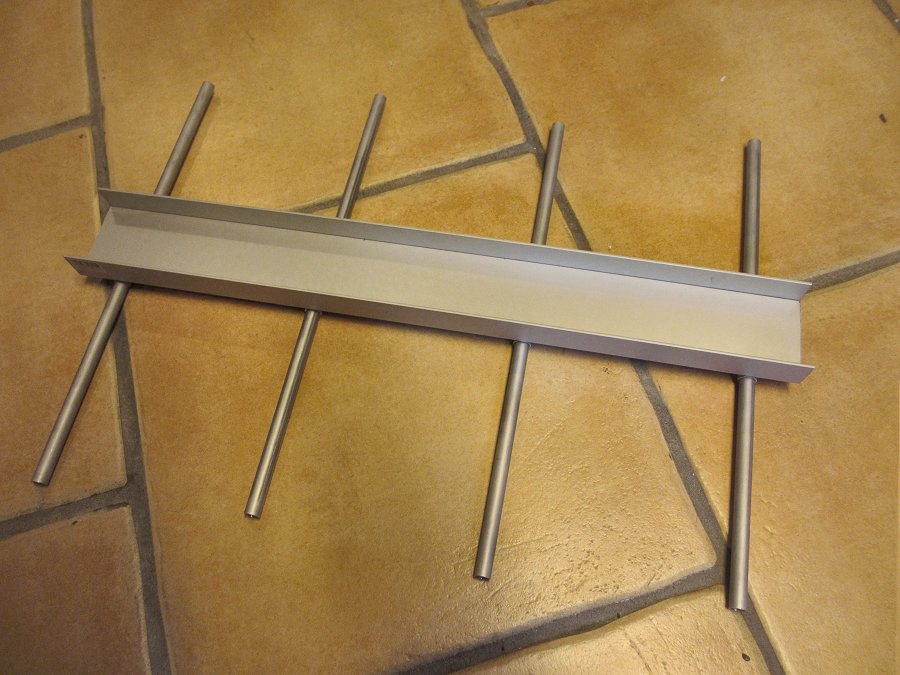

Aluminium tube, cut into sections and fitted underneath the cassette.

Thinner aluminimum tube. Also available in brass - possibly better, but costly and heavy.

Thin tubes slide into thicker tubes…

…resulting in this beast: A traverser-style sliding cassette.

Frame built from 10mm foamboard. Ahem!

Plastic angle and screws, used to secure tubes to frame. Rawplugs inside the tubes.

Everything fitted together. Looks OK but does it work? At first I wasn’t happy. There was a bit too much friction when sliding the cassette. The foamboard was still nice and square though, so I must have not got the tubes perfectly aligned. With four tubes there is very little room for inaccuracy.

So I removed the two outermost “guide tubes” from the cassette, and fitted foam pads in their place (track underlay). The foam slides on top of the outermost tubes, meaning there is still support at the ends.

With this arrangement, the cassette slides smoothly. I have added a cork underlay and am now waiting for fresh supplies of Sprat & Winkle uncoupling magnets, which will be installed in the cork-base on the right hand side so I can use delayed action S&W couplers. The wooden “lip” connects the traverser to the layout through a piggy-back arrangement.

Testing suggests that so far this contraption works surprisingly well. The bumblebee flies. The big question is for how long! There’s clearly a risk that the foamboard will warp or get twisted from heavy use. If that happens, I’ll try a Mk2 version with a wood frame.

-

11

11

-

2

2

30 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now