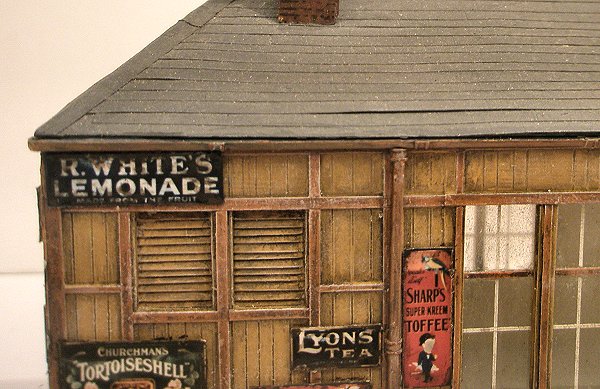

I've been looking at options for modelling the slate roof on the goods depot at Farthing. For what it's worth, here's a quick overview of the options considered. Above is one way of doing it: Lengths of thin card strips scribed vertically, and overlaid. I think this can give good results - in 4mm at least.

But thin card also has its drawbacks! I recently noticed that the roof on the parcels office at Farthing has buckled. Either the glue has simply let go, or it was caused by a repaint I did a while back. Using the same method but with plasticard might have been better, as convincingly demonstrated in this blog entry by 45584 (albeit in Gauge 1!).

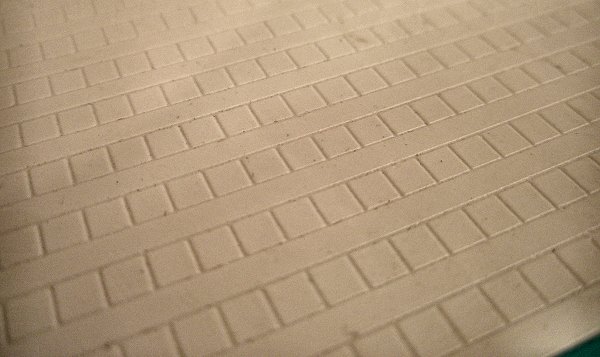

An alternative to scribing things yourself are these "ready-scribed" slate sheets from Slaters (ref no. 0427). The idea (I think!) is that you cut out each length and overlay them.

I may have failed to grasp the concept here, but my experiments with the Slater's sheets suggest a significant overscale thickness of the slates (according to the Slaters catalogue, the plasticard thickness is 0.015'). Or have I misunderstood something? Until someone tells me differently, I've decided not to continue down this road.

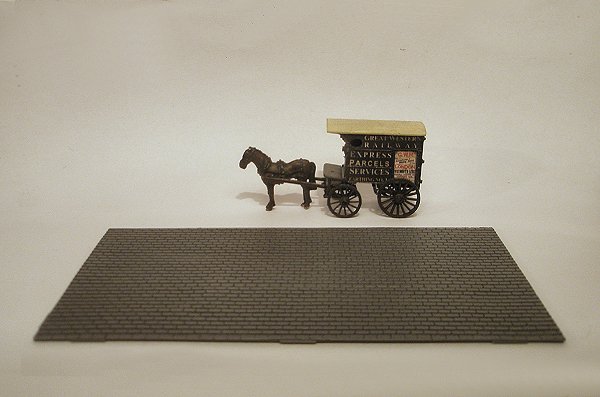

A third main option is of course the ready-to-fit embossed sheets, available in various guises. There seems to be two main types here: Those that are printed "flat", and those where the slates actually appear to "overlap". The flat-printed ones can sometimes work well: This roof on a (rather careworn) Coopercraft platelayer's hut gives a reasonable representation, I think.

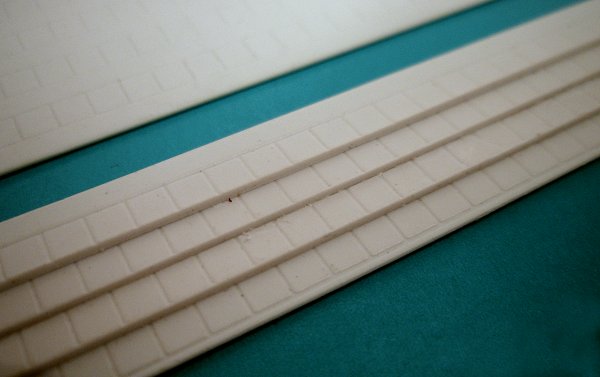

However, the Wills slate sheets seem to me the best of the ready-embossed solutions I've seen yet. The shingles actually give the impression of overlapping....

...and they have an ever so slight irregularity that can be further accentuated during painting and weathering, as on the right.

But of course, nothing is perfect. One well-known issue with the Wills sheets is their limited size, which means several have to be joined for larger rooves...

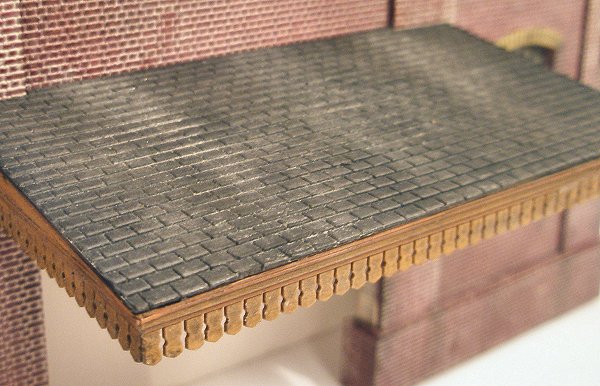

....and another issue is their thickness. I don't think the individual shingles look overly thick, but at the edges it becomes more of a problem, as seen on this canopy on the goods depot. Nevertheless, so far I think I'll go ahead with the Wills sheets as the preferred choice.

Update Feb. 2019:

Since this post was written I have experimented with:

- Pre-cut slate sheets from York Modelmaking (more on that here)

- Slate strips cut from vinyl (more on that here).

-

7

7

10 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now