All those close-ups of Code 100 track in my past couple of entries made me want to push ahead with the C+L track for "The depot". So here's a little interlude to the "All in a day's work" story, showing what I've been up to with the track inside the depot.

Timbertracks panels stuck down, sleepers shortened to appropriate length, and webbing removed (see the earlier dicussion in this entry). Next time I'll just lay some individual timbers!

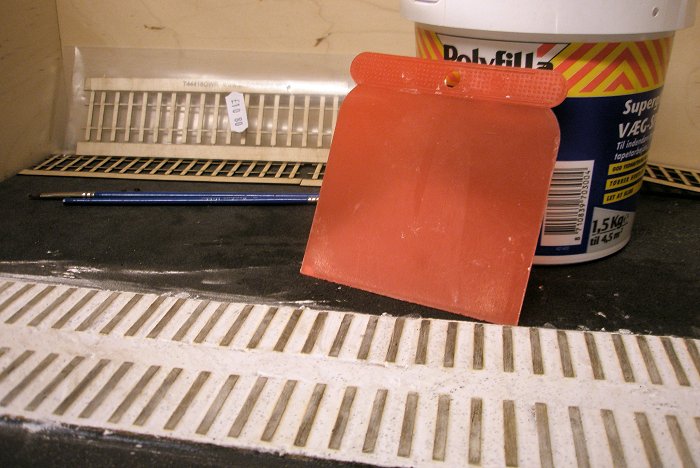

The track is inside a goods depot, so I wanted that look where the timbers are almost embedded in the ground. Using the plastic filling knife in the photo, I "dragged" Polyfilla at a 45 degree angle across the timbers, until it was level with the timber tops.

When the Polyfilla dries up it contracts a little, leaving the timbers just proud of the ground. A slight "shoulder" is left on some timbers, which I scraped away with a scalpel.

The result was more or less what I was after: Timbers slightly proud of the ground. But they are looking a bit thirsty!

The Polyfilla residue on the timbers was cleaned off with a wet cloth (you'll notice the high-tech approaches here!) ...

...and the timbers were given a bit of thinned matt varnish to restore some of their colour. I should've done this before laying the timbers, which would also have prevented the original wood stain from seeping into the Polyfilla. I managed to cover this by rubbing dry Polyfilla powder into it.

After giving the ground a light wash of grey and cork, I laid the track. The chairs were threaded on to the rail first, and then stuck down with Butanone. I was worried if the latter would give a strong bond, since the timbers had been exposed to quite a lot at this point! So far I am satisifed, but time will tell. It seems there are as many experiences with Butanone as there are modellers!

Hey dude, want some good dust? A heady mix of white baby talc (sic) and Carr's light grey weathering powder. Rock and roll! This was brushed across the track to blend things together and tone down colours.

C+L etched fishplates, shortened to simulate the GWR type. I bet you can't see the gap in the rails. See how good a joiner I am? ;-)

That's it then. I do wonder if the timbers are a bit too light, but things will look darker once the depot is placed around them.

-

25

25

21 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now