5726 - Experiments with 3D Printed detailing parts

Other B9 Creator users have had some impressive results using Spot-HT resin, in particular for small highly detailed components (see Rab's creations!). The main difference with this resin to the proprietary B9 resins is that you cannot use it for casting, it is also much less viscous which should mean that it settles quicker. I'd just about enough life left in the layer of PDMS for another print, so today I tested printing some detailing components using Spot-HT. The test parts I've roughly drawn up in Sketchup, some will need a little more work depending on the results of the print. The test pieces were:

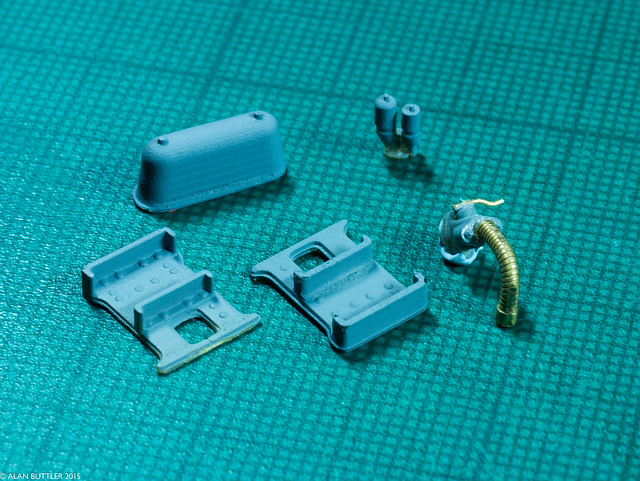

4x Pannier tank rear steps

1x Top feed for 74xx

12x GWR Whistles pairs and mounting bracket

14x Steam heating hose cocks

First up, the steps have come out really well, with a thickness of 0.5mm they look just right. The rivet detail has come out nicely but I will probably increase the size next time round. There is some flash to remove from the edges of the steps, due to the positioning on the build table. Another thing for next time is printing these small components on a sprue. They were a devil to get off the build table without damaging! That said, this material is pretty tough even before curing under UV light.

The whistles have lost quite a lot of their detail but I think this is down to the clouding of the PDMS. However, the small nut on top of the whistles has printed really well, considering its 0.25mm wide its pretty amazing! The steam heating hose cocks also look pretty good, with the addition of a turned brass pipe and handle made from 0.4mm handrail wire. However both these items are slightly overscale, I'll have to get the micrometer out next time and make them more accurate!

For now that's it for printing. I'm waiting on my spare vat to return from the USA as its being fitted with a replacement for PDMS called Nuvat, developed by Evert on the B9 Creator forum (details here). This new material should last a lot longer than PDMS.

Edited by alanbuttler

-

6

6

.thumb.jpeg.3955886fc58580247a46965a1bd9db57.jpeg)

3 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now