Weighing up the Dean Goods

I have been taking advantage of the Spring Sales and have bought myself a BR black engine driven Oxford Rail Dean Goods.

I bought my first Dean Goods back in 1985. It was a Mainline model with a tender drive. The perceived wisdom was that the model was conceived and designed by Airfix just before that company folded. I thought the tender drive came with an unrealistically high mound of coal, to hide the motor, and it could be noisy. It did have a good haulage capacity.

Mainline Dean Goods from 1985

I thought the model well detailed for its age and I believe reasonably accurate. It was one of the earliest mass produced models to feature blackened coupling rods.

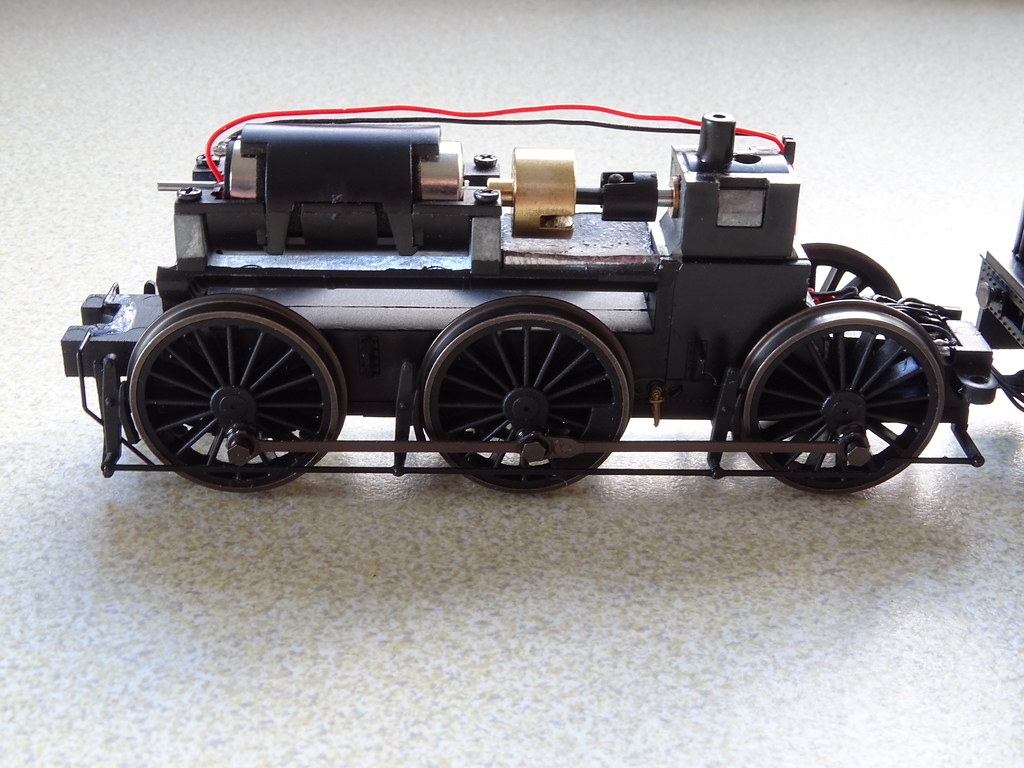

Oxford Rail Dean Goods from 2017

Moving forward to 2017, Oxford Rail introduced an engine driven Dean Goods. This model has generated significant ‘froth’ from modellers, particularly those interested in pre-nationalisation engines who note numerous dimensional and detailed deviations from the prototype. The first release by Oxford Rail had a mechanism with twin flywheels. This was well received. Subsequent releases have a different motor with a single flywheel. These later models, particularly the sound fitted version, have attracted negative comments reporting jerky and erratic running.

CLICK ON THE PICTURE TO WATCH A VIDEO OF THE Oxford Rail Dean Goods – straight out of the box

Out of the box my Oxford Rail Dean Goods ran smoothly and quietly – I was impressed. However when I took it up and down and round and about (with eight wagons), it couldn’t get up my 1 in 56 gradients. I was disappointed.

The prototype Dean Goods is a little engine and it is not surprising that Oxford Rail’s model weighs under the 200gm (including tender). I would see if the weight could be increased.

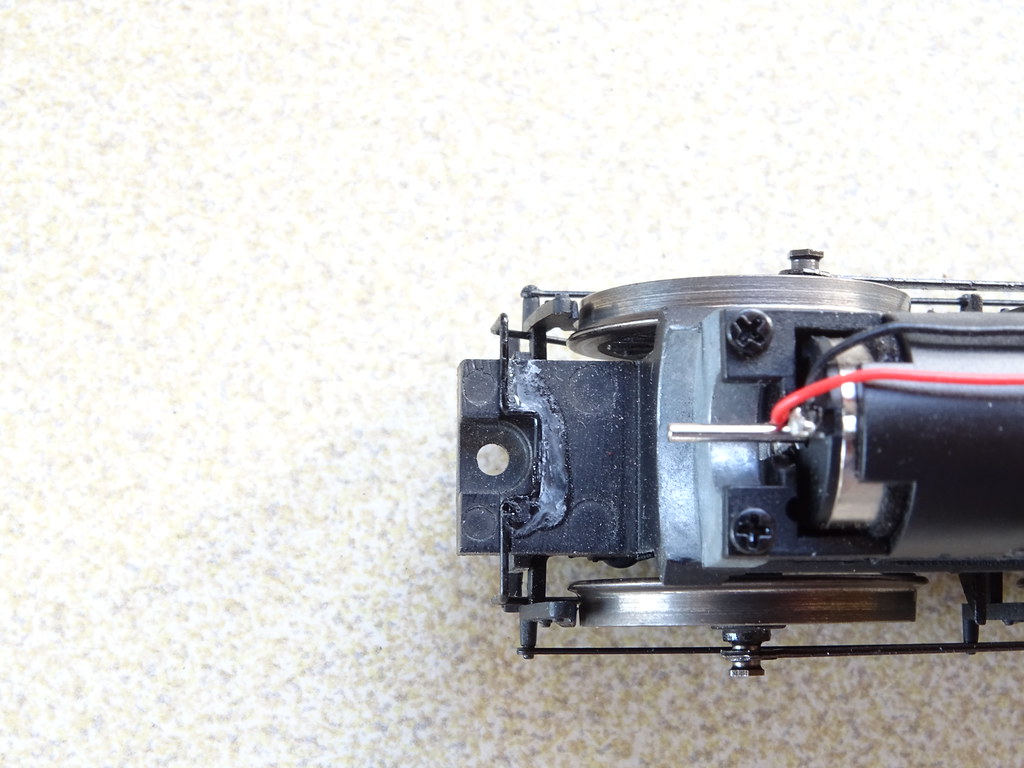

Oxford Rail Dean Goods chassis – NB added lead beneath the flywheel

On inspection there is quite a lot of unused space within the model and I was easily able to add 3gm of lead to the chassis beneath the flywheel. There is further space beneath the motor but I left this empty as I did not want the motor overheating.

Spot the lead

Turning my attention to the body shell I identified four locations to add some lead. I filled the dome and safety valve with lead shot, sealing the former with a plug of lead glued in place with super glue(6gm). I glued two circles of lead, cut from sheet, into the smoke box (8gm). Finally I fixed two slabs of lead, shaped to fit into the sides of the firebox (12gm). In total I increased the weight of the engine and tender from around 195 to 225gm.

CLICK ON THE PICTURE TO WATCH A VIDEO OF THE Oxford Dean Goods – standing start on 1 in 56 gradient

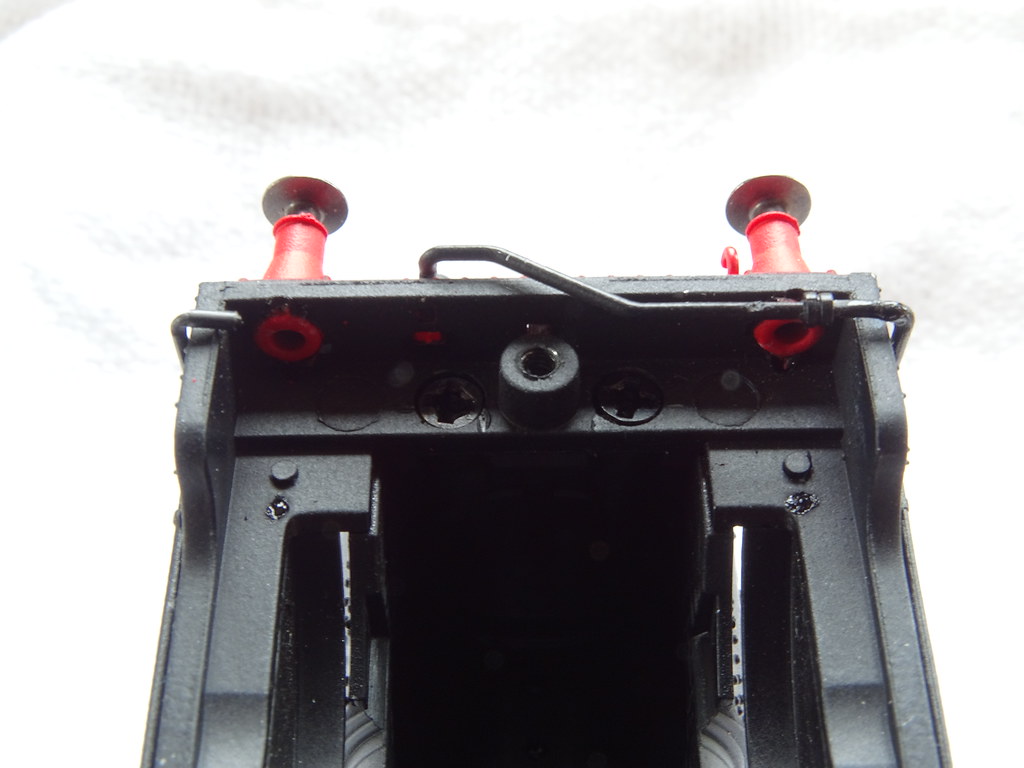

I had also read somebody’s blog saying that they thought that the tender was propping up the rear of the locomotive. The tender to engine coupling was certainly very rigid and I slackened off the coupling screw beneath the tender to give more vertical movement. As the video shows the newly weighted model with extra flexibility between engine and tender could now easily start eight wagons on my 1 in 56 gradient.

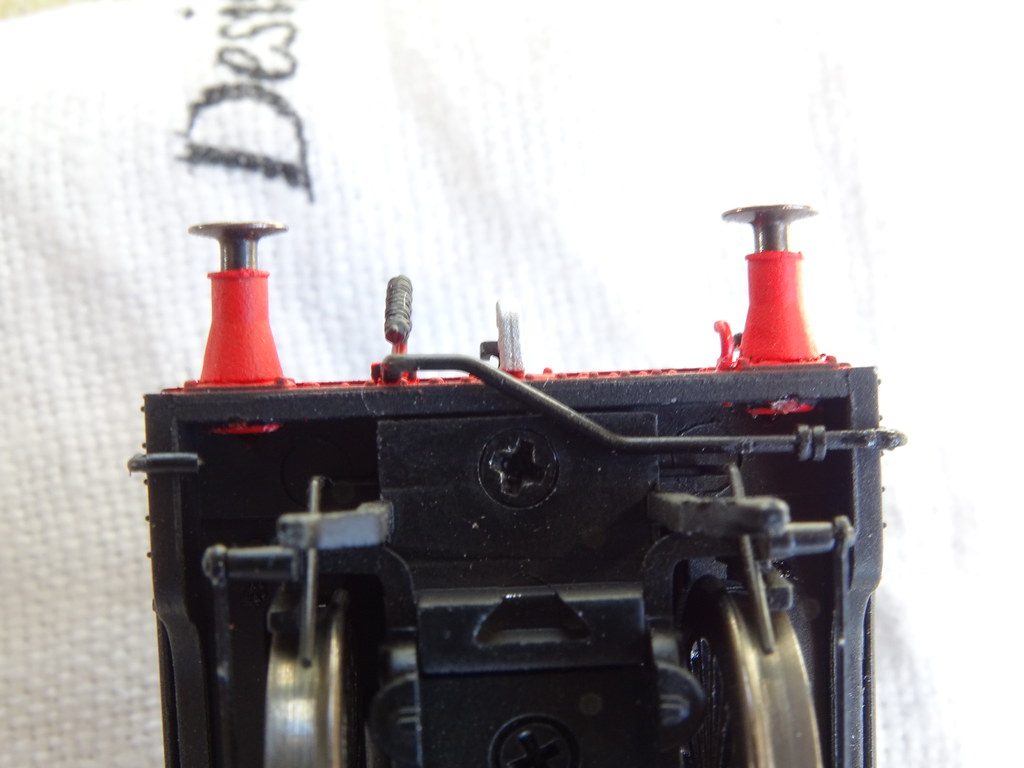

Oxford Rail Dean Goods – dummy vacuum pipe

To fit the lead into the body shell I had to ‘get inside’. At the front the coupling pocket has to be removed to gain access to the single front fixing screw. At the rear there are two screws beneath the cab. I had to carefully angle the screw driver to prevent damage to the brake rodding assembly. However there is another problem which I hadn’t noticed. There is a dummy vacuum pipe running across the front of the engine beneath the buffer beam. I am guessing that I snapped this when I lifted the body off the chassis because the dummy pipe was loose in two pieces with a 5mm gap.

Oxford Rail Dean Goods – dummy vacuum pipe after repair

There is a dummy coupling in the vacuum pipe which I suspect is meant to separate and allow the body to be lifted clear. That is how I have reinstated the pipe - using a bit of circular section plastic cut from an old handrail, glued at one end and left as a push fit at the other. All good fun.

Oxford Rail Dean Goods from 2017

I now have a much more useful model. However I still have two ‘niggles’ to sort. Firstly I need to fit a front number and secondly I would like to better disguise the horizontal join beneath the boiler between the upper plastic boiler and the lower metal motor support. It occurs to me that if the body and chassis could be pulled more tightly together the latter join would not be so visible. I will share two more pictures that I made whilst body and chassis were separated.

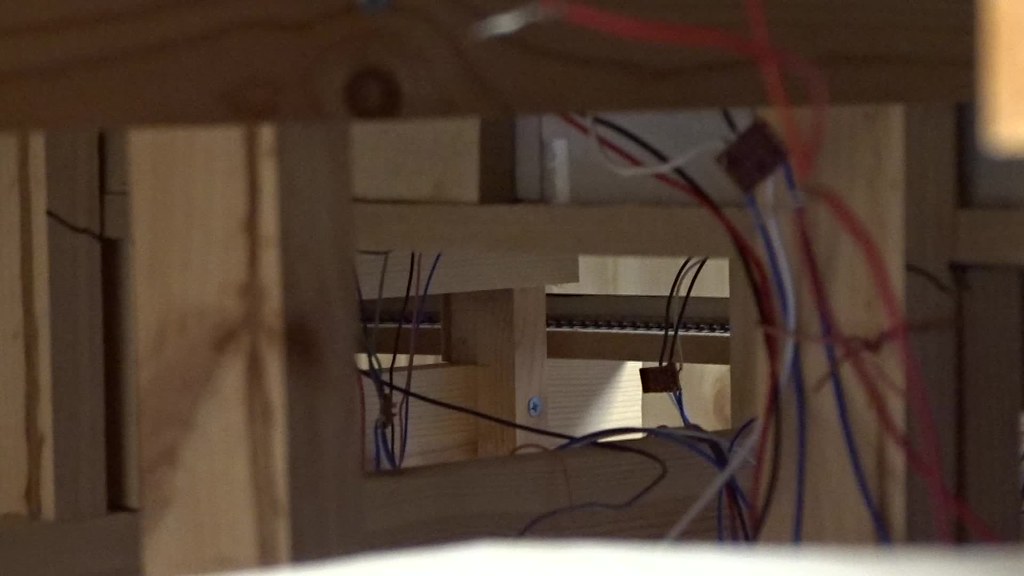

Oxford Rail Dean Goods –chassis front end

At the front end it seems to me that the body and chassis cannot be pulled completely together because of the wire fitting for the brake rods.

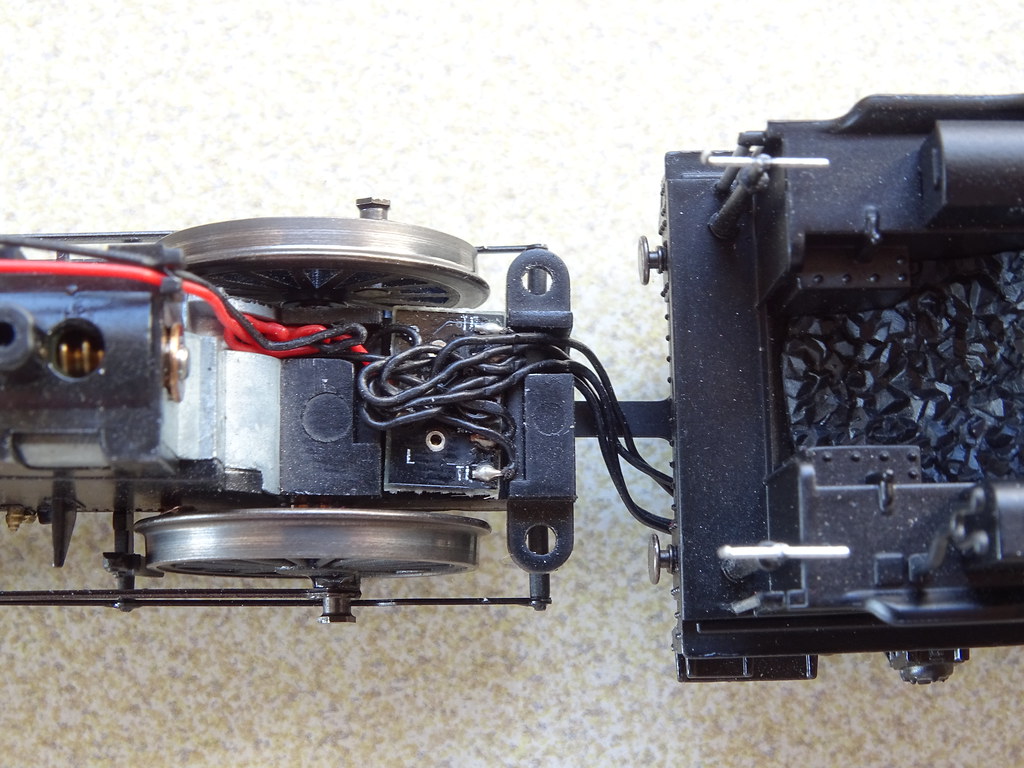

Oxford Rail Dean Goods – chassis rear end

At the rear end there is what I would call a ‘rats nest’ of wires that are supposed to tuck beneath the cab. Looking closely at the picture there are crease marks in these wires where the body shell has been cutting into the wires. To date I have not investigated further but for those modellers with locomotives that jerk and run erratically I would start investigating here for broken wires!

As a parting thought I am attaching an image that I came across on the web, appologies if I am breaking someone's copyright.

- a super image showing a Dean Goods working out its last few years.

For some thoughts on and actions regarding a pre-nationalisation model look no further than the Farthing Layouts:

http://farthinglayouts.blogspot.com/2017/11/backdating-oxford-rail-dean-goods-1.html

Yet more impressive work from Mikkel

Edited by Silver Sidelines

-

1

1

.thumb.jpg.60c53fcbcaa34017b05b8919d1a9e6d2.jpg)

10 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now