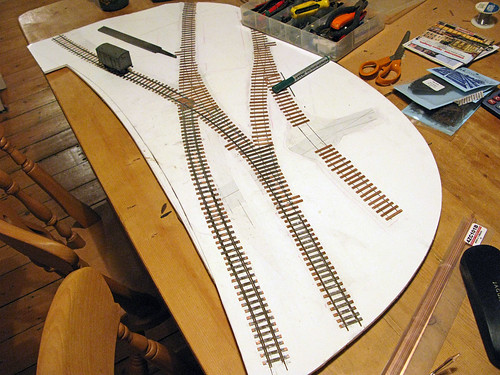

Track Laying on Brewhouse Quay

nevard_110204_brewhouseQ_IMG_9104_web, originally uploaded by nevardmedia.

Track laying has now started in earnest on my brewery project. Because the layout will be presented diorama style with a high curved backscene on 3 sides as mentioned on previous posts, I'm laying the track 'off set' using a 5mm foamboard sub-base which will be firmly bonded to the proper plywood base once most of the fiddly stuff has been done. It's much easier to work this way because I can spin the base around to suit and really ensure that the trackwork is all properly aligned without having to resort to some kind of contortion act. Good track is something that is particularly important with a layout which will mainly be running 4 wheeled locos, though of course one should always aim for well laid track irrespective of what one is running.

Much of the trackwork on the left hand side (which is next to the canal basin) will be embedded in sets (cobbles), so armchair modellers shouldn't worry too much about the iffy sleeper spacing. Note the check rails on the nearest line in preparation for the 'sets' which will probably be scribed Humbrol Air Clay.

8 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now