Silk Purse? – Airfix tender drive County

There have been questions about the mechanism of Hornby’s Hawksworth County. I was inspired to revisit an elderly Dapol County - ‘one that I made earlier’.

Dapol County with Airfix Tender Drive

My original model, County of Stafford - Dapol D4, dates from May 1984. It was purchased from the Oxford Publishing Company for the then not inconsiderable sum of £34.50. I think it was the first ready to run engine with a tender fall plate. I do believe the shape of the cab roof is wrong and that the fire box detail is incorrect. However I think it can still make a presentable model.

1013 County of Dorset

Fitting sprung buffers, lamp irons, new smoke box door handles and a set of etched plates makes for an improvement.

Sprung buffers, lamp irons and new door handles

What about the mechanics? The Dapol County came with a huge lump of lead in its smokebox. However even with all its ballast there was lots of noise and lots of wheel slip and it could not manage seven coaches on the gradients of my layout. I had a solution – I had already fitted an Airfix tender drive unit into a flat sided Castle tender. I would do the same for the County.

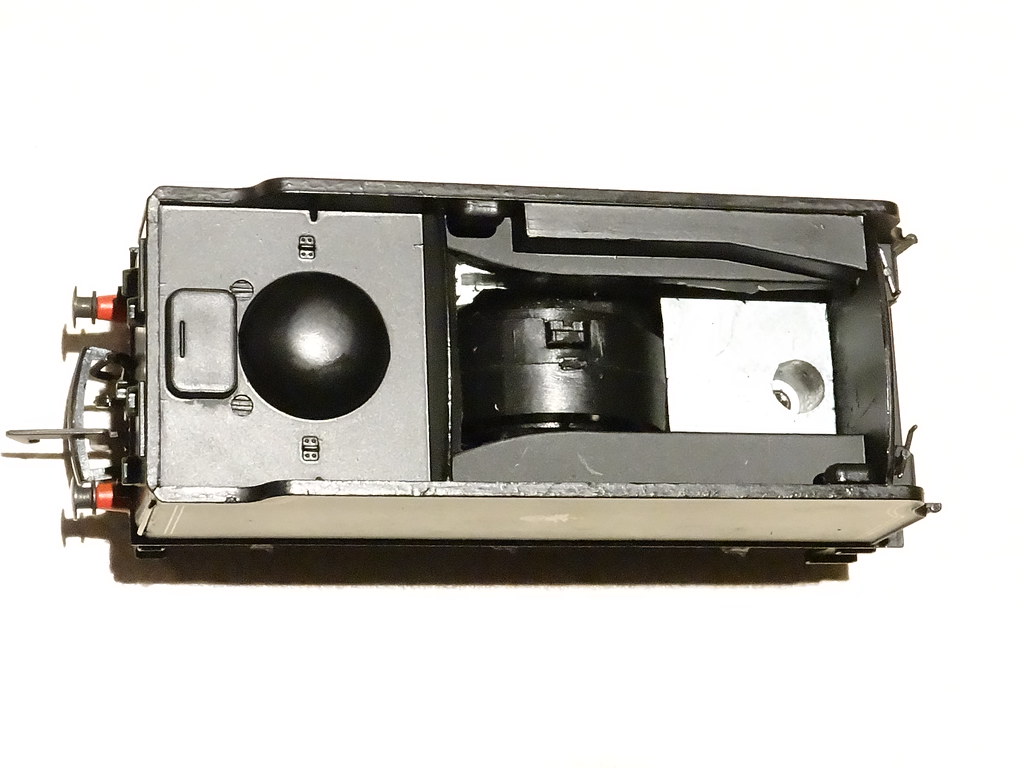

Hawksworth Airfix Tender Drive

Altering the flat sided tender to fit on the standard Airfix tender drive unit with the Churchward underframe was relatively straightforward. Fitting the Hawksworth underframe was more difficult.

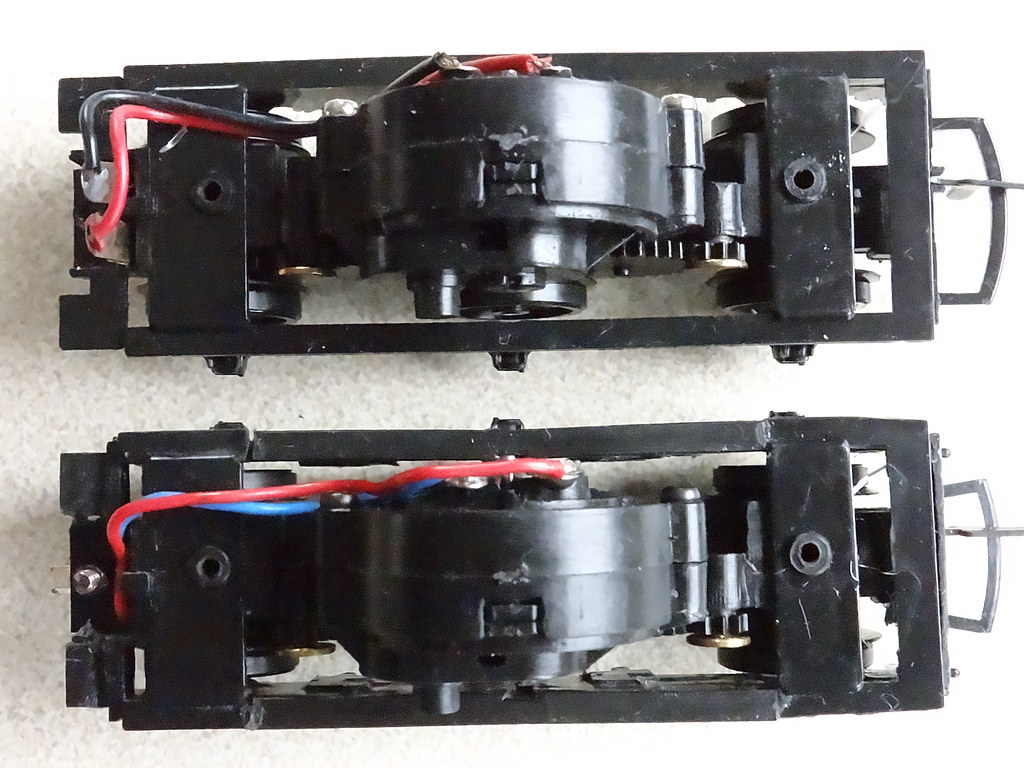

Hawksworth (left) Churchward (right)

My solution was to take the front and rear top sections from the Airfix Churchward underframe and to splice these onto the top of the new Hawksworth underframe.

Original Airfix (top) Hawksworth (bottom)

The underframes seem to be moulded in a nylon type of plastic and I used a Loctite ‘all plastics’ adhesive to fasten the bits together.

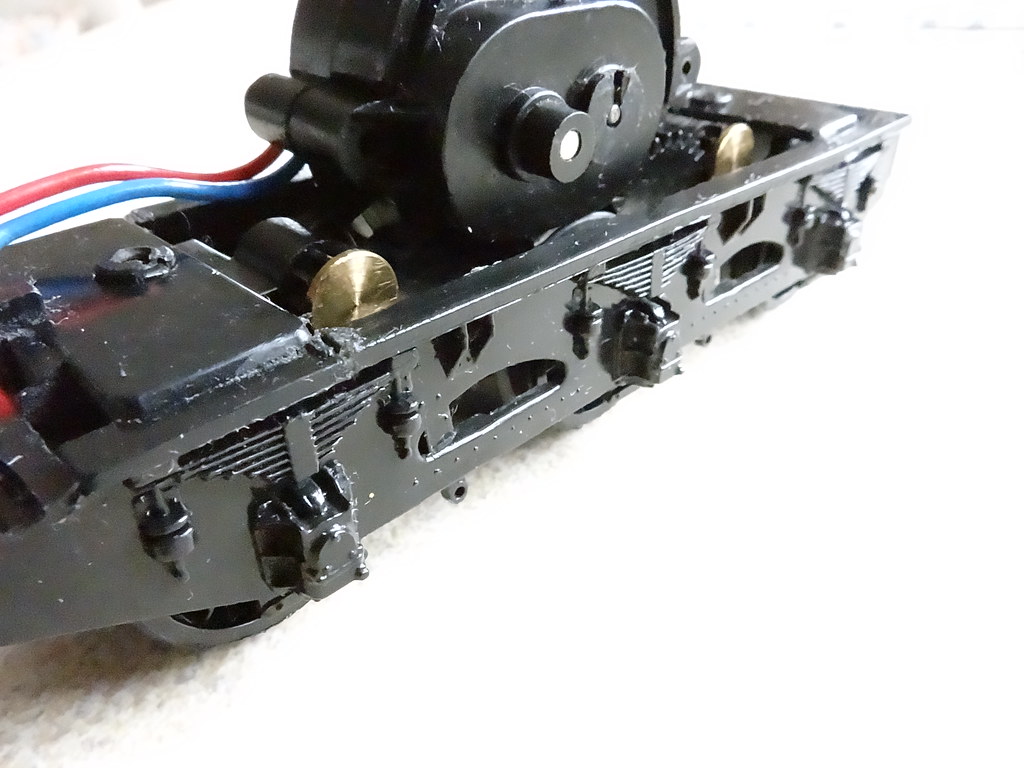

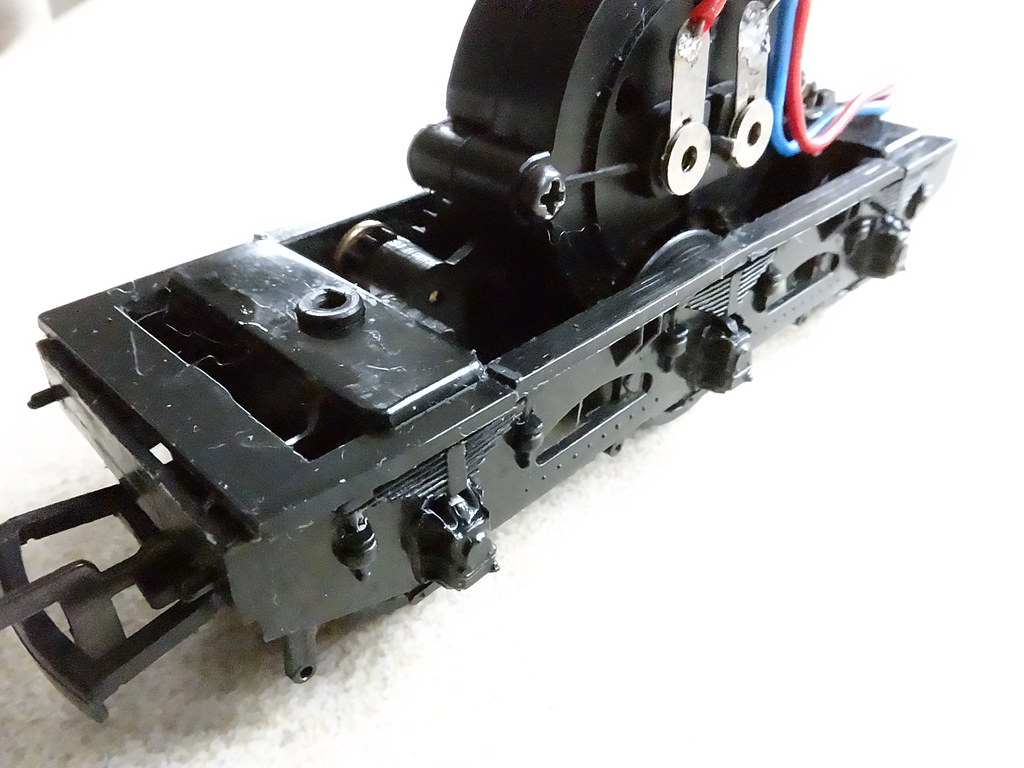

Airfix Hawksworth Underframe

The view below shows the two pins that locate the underframe into the rear of the body shell. These pins are relatively fragile. If broken they are easy to replace. I drilled a 0.5mm hole where the pin had broken off and then pushed a brass dressmaking pin back through the newly formed hole and cut to size.

Hawksworth Underframe

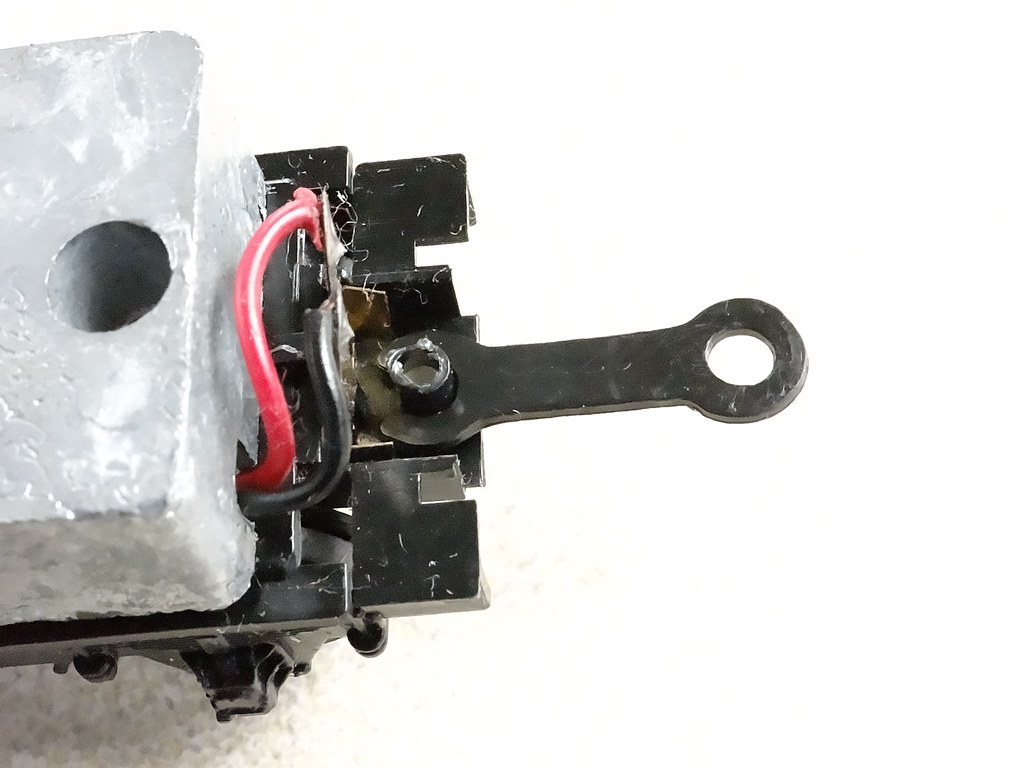

I found the biggest difficulty was dealing with the electrical connections at the front of the tender.

Airfix spade connectors

It seemed to me that there was no room for the Airfix spade connectors under my Hawksworth tender footplate. Instead I fitted a miniature plug and socket from the mother board off an old computer. I think I changed the wires from the brushes to single core which meant that I could bend and shape them to fit below the tender footplate. There is a little bit if trial and error positioning these wires to enable the front of the tender body to sit down at the same height as the cab footplate.

Miniature plug and socket

In order to fit the plastic body I chose to leave the Airfix mechanism and weights untouched. I used a combination of craft knife and cutting disc to pare away at the plastic around the coal space.

Fitting the body shell

Amazingly the Airfix mechanism and weights are a perfect fit for the coal space of the Hawksworth tender. However to continue using the two location pins in the rear bufferbeam I found it necessary to shave away some additional plastic from the back of the tender front where it slides and pivots over the Airfix lead weight during fitting.

Bubble wrap

What about a new coal load? I used some thin plastic bubble wrap held in place with super glue. The bubble wrap must be thin enough to mould around the Airfix motor but rough enough to represent coal when painted black.

Coal load

I think a good outcome. How does it run – very well. There is a

-

4

4

.thumb.jpg.60c53fcbcaa34017b05b8919d1a9e6d2.jpg)

7 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now