I'm still working on having things moving on the layout at Expo with under three weeks remaining.

Several weeks ago a pleasant suprise landed in my inbox, an opportunity to test build two new locomotive chassis kits. A short exchange of emails later and a subsequent jiffy packet arriving through the letter box and we were away.

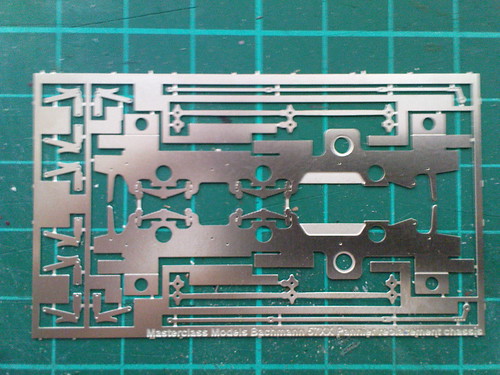

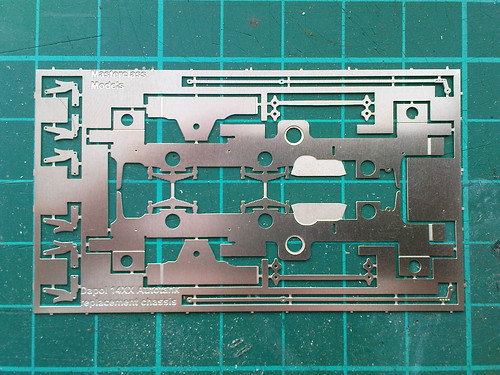

The chassis are to fit the GF 57xx body and the Dapol 0-4-2T

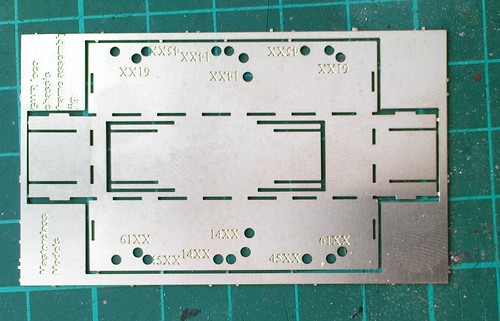

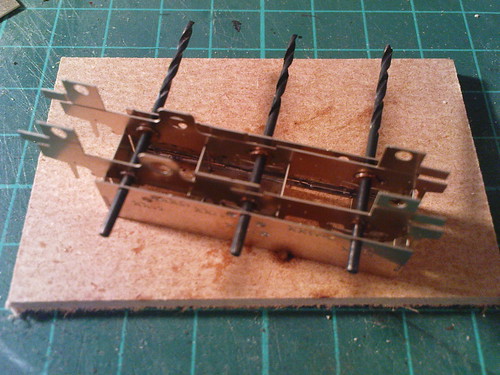

Also included was a jig for assembling the frames

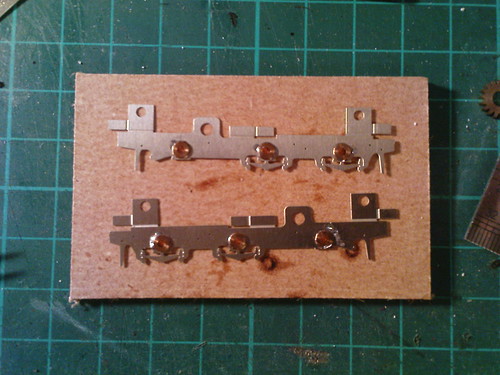

First the frames are bushed before inserting into the jig, which is easily folded up sqaure using the tabs and markers provided.

It is best to open up the bearing holes first and use 1.6mm drills to locate in the jig. I found this out afterwards. Phosphor bronze and even PCB frames are much stiffer than etched under the pillar drill!

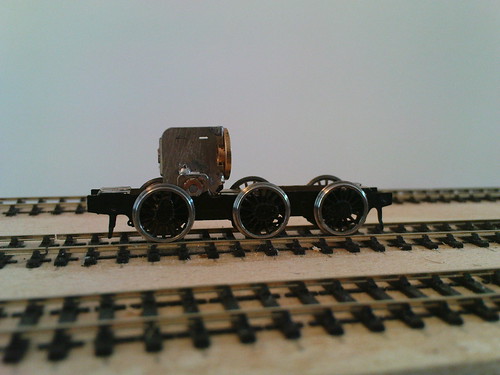

Next up the pick up springs were added and the motor mount attached...

...followed by gears and wheels. I quarter wheels by hand/eye.

Next up was the brake assembly.

I wanted to make these removable so set about insulating them from the frames to allow a complete cross piece from 0.3mm n/s wire through the bottom. Short pins of microrod were added at the top of the brake arms to locate into the holes in the frames. Once painted they are insulated.

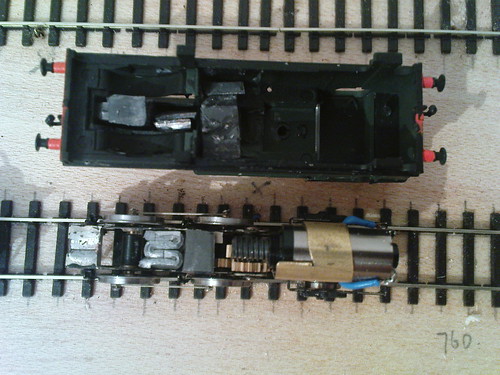

Here the locomotives are pictured working and near complete. Both have 8mm coreless motors. The bodies have had no detailing, but there is some minor interior modification to allow fitment of extra weight.

This is especially true of the Dapol body. I mounted the motor the easy way (into the cab) and have virtually run out of space for lead to move the balance forward to gain better electrical pick up and adhesion.

-

1

1

11 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now