After several peoples Kind advice I have tweaked things more.

so, progress. The original droppers have been unsoldered and dumped and two of these have been made...

They have to 'low lift mech' ' in place, which to be honest don't look that out of place to me. Certainly after rust paint they will blend in.

Next was another reaf of the Tortoise instructions. It says to not use a powerful iron and to use a small tip. My soldering station is a Weller 40Watt jobby. Don't know if this is a problem but I just made sure I was, Flux, solder In and Out quick on high heat. 450c. Pssssz...done. Tested an no problems. 0.45 brass wire was used.

Next I cut and glued a block of wood the the board, deemed nessasary for having a tie-bar in the way. This was then pilot drilled in the middle and secured with a counter sunk screw. Counter sunk by over tightening I might add! Was only MDF.

Two screws are losely in place, two others need doing also.

Next was for me to set the motor up and test it. The operating wire was shaped, trimmed to size and installed...don't think much to that retaining screw as it was a ###### to get in.

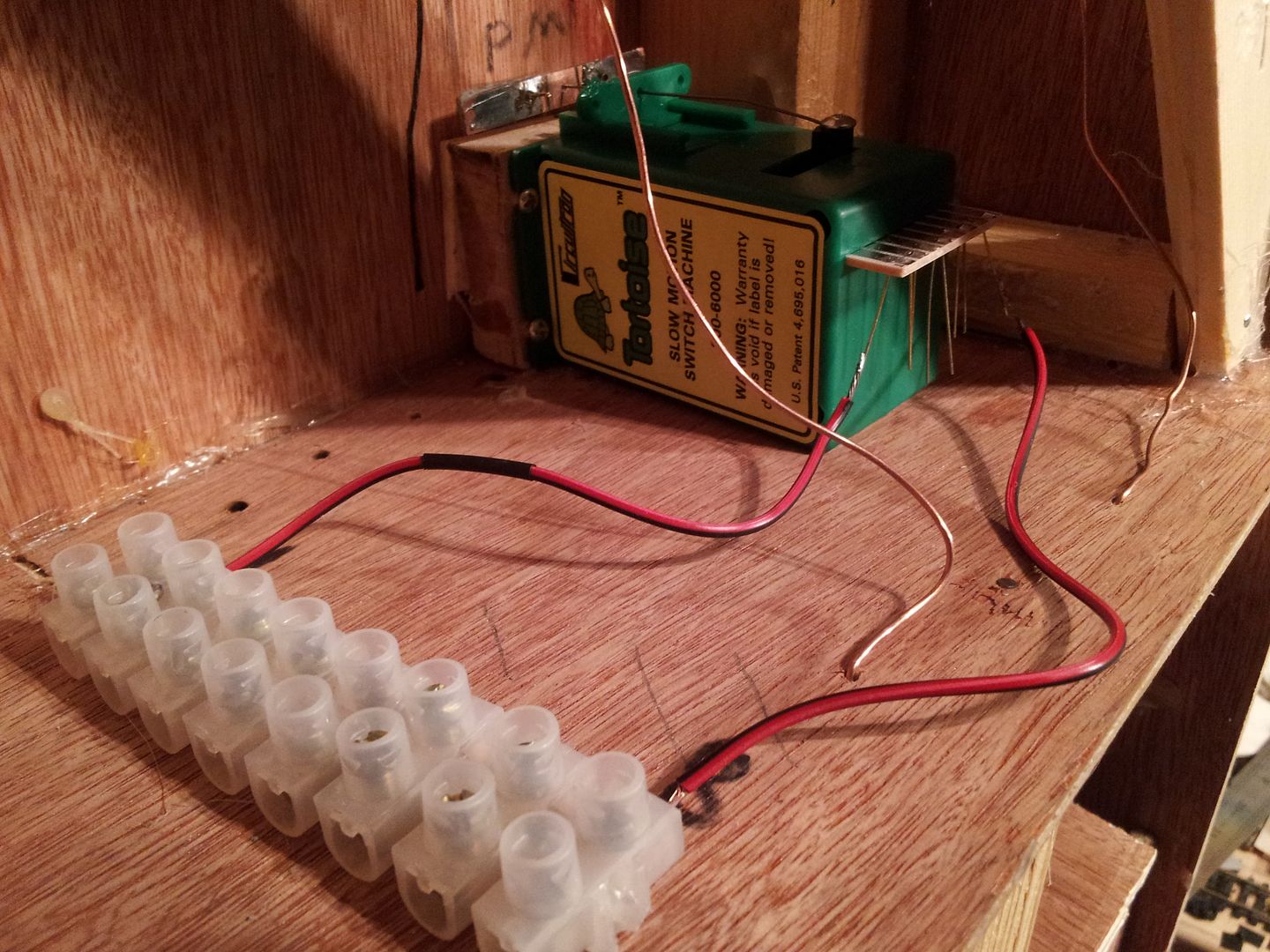

As per instruction advice I set some terminal blocks up. 1 and 8 were connected to my DC controller and we were away. It took a while to get the throw happy as it was biased to one side but after tweaking the tie-bar position, the green slider and reprofiling the switch blades just a tad, it's all hapy now. As it seems fine I'll leave the mechanical aspects and just concentrate on the rest of the electrics.

I'll try the tube methods on my next turnout, and if this one in time goes a knacker I'll know what to do. All in all an enjoyable experience so far.

-

4

4

2 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now