The point motors will have to wait a while as I have not brought any yet.

Basic track wiring is done minus any turnout feeds.

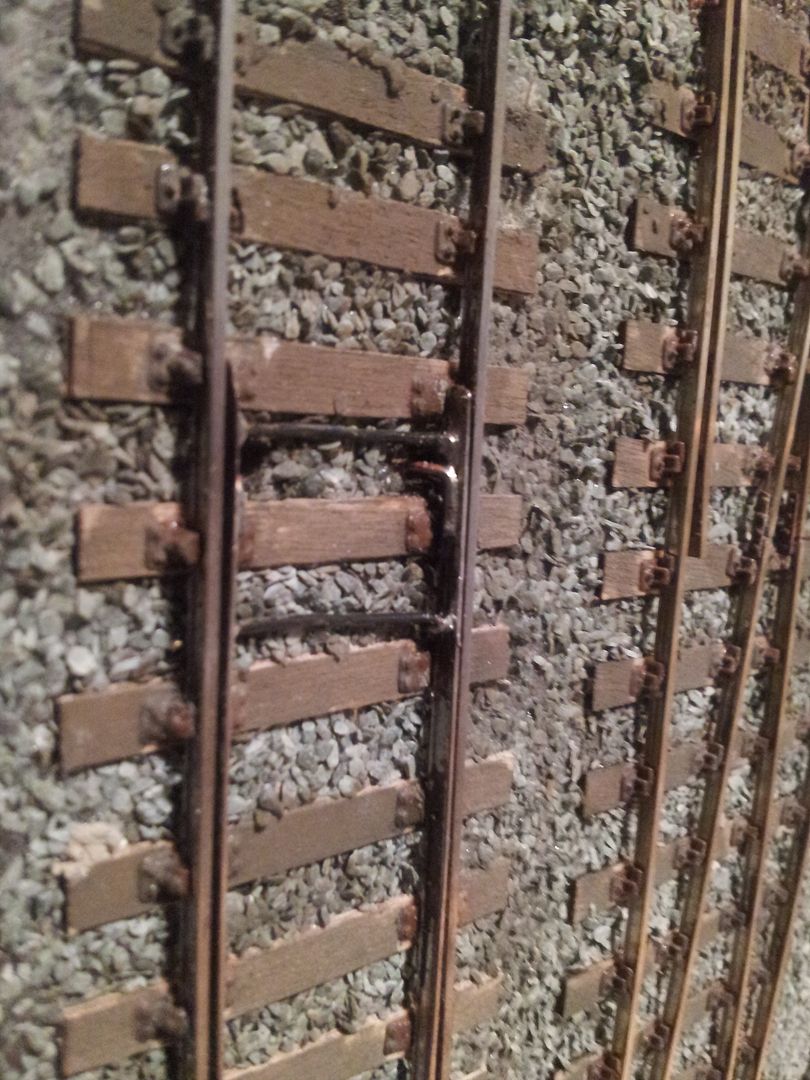

I have a serious problem. I started my first TOU using 0.7mm brass rod soldered to the rail webs through generous holes onto some gapped PCB with a drill hole. Had no sleepers so quickely cobbled up my own.

The problem may only be with this one point because the switch rails are bent ever so slightly upward so whenever I 'operate' the tie-bar with a wire powered by hand the switch blades switch with a rocking arch thus putting the rails in the air somewhat. Is there any way to solve this other than destroying half the point? Also will this method work on the other switch rails that are closer to perfect or am I again accidently making pork scratchings?

3pcs

I really need help with the above as I'm stuck otherwise. :-(

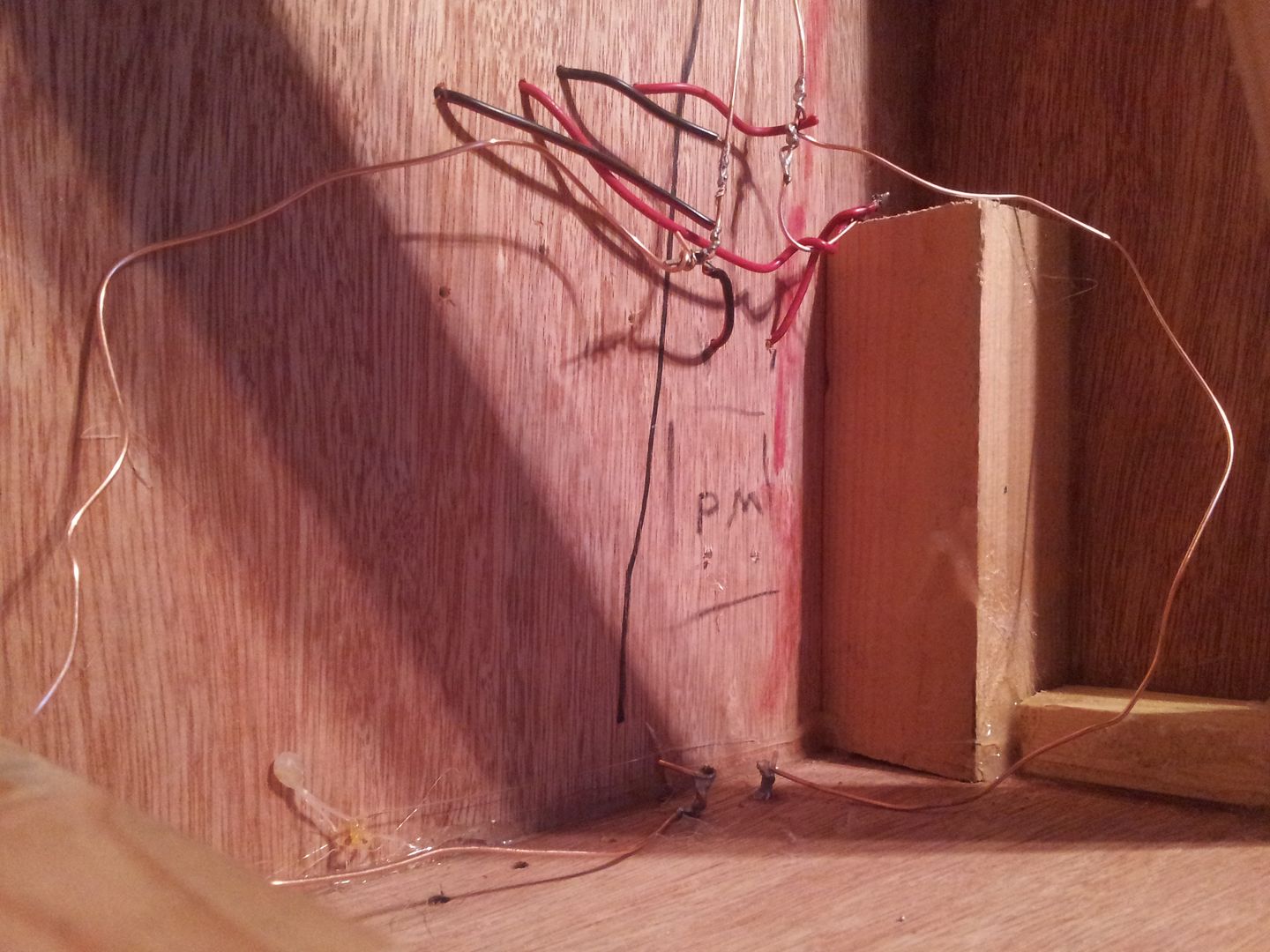

Before the above I finished the track wiring as already said but came across a problem and sorted it. The bus wires were in the way of a proposed point motor. Solved by soldering hollow square shaped bus wires onto the original and cliping the original bits out of the way thus re routing them, easy.

2pics...

And again before that I with a little help cobbled up some scrap metal into shape, coated it in foam and tape and screwed it into a baton. Reason being the layout currently rests on this baton above my bed and the other end now has legs. With this new mod it means I can have the layout a foot lower so instead of the baton it just rests on a dropping hook and instead of legs the chest of drawers. modular and easy.

King of Bodge me!

Please help with the above if you can. Also any typo's I use my phone typing as excuse.

6 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now