Jointed Coupling Rods and some other issues with Hornby Duke of Gloucester

I was my intention to finish with Duke of Gloucester (DoG) and to move on. First however I would just fit some jointed coupling rods (from a Britannia). It seems that nothing is quite that straightforward with my model and I uncovered some other issues that hopefully will not bother too many of you, but just might be of interest to some of you.

Hornby R3191 Duke of Gloucester – a rare view in service

When first taken out of the box my model was a reluctant runner first crawling and then speeding up and then crawling again. I thought that I had cured this behaviour when I removed the bottom plate and adjusted the pickups. Well this weekend when trying to reverse the loco (on curved track) I was aware of a shower of sparks from beneath the driver’s side of the cab!

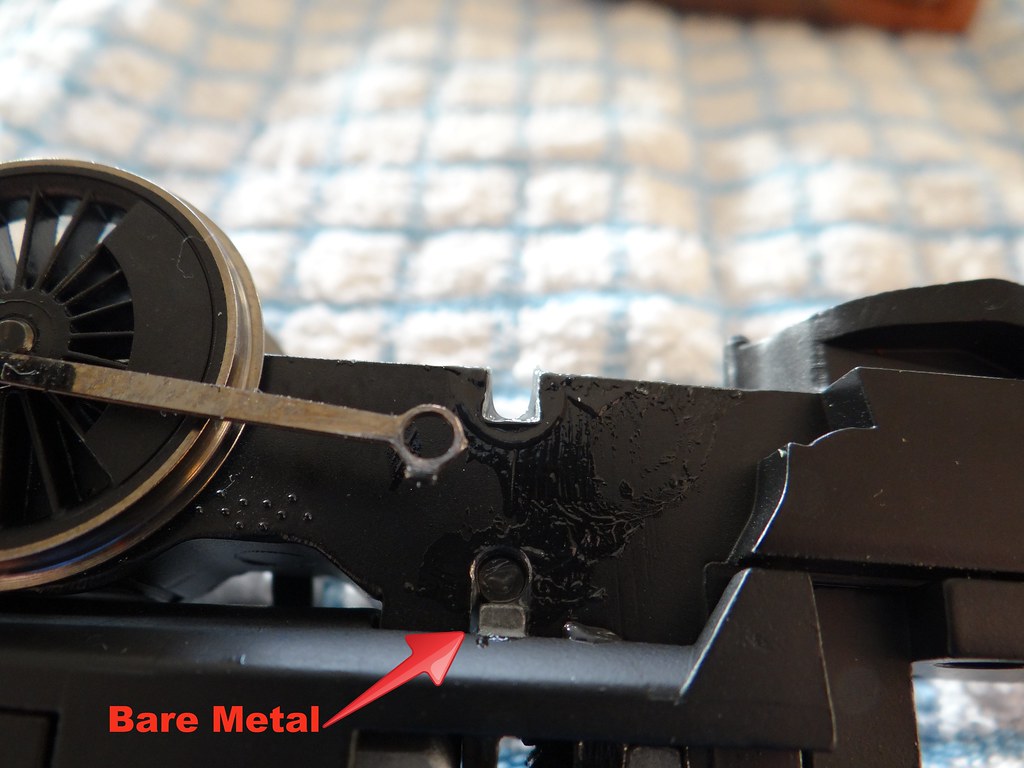

The picture below was taken when the engine first arrived but I have added the little red arrow to highlight a patch of bare metal – part of the gear mechanism which seems to protrude on one side more than the other.

Bare metal

Now that my engine has ‘run in’ (started to wear out) there is seemingly sufficient ‘play’ in the drive axle to allow the top of the wheel to come close to this area of bare metal resulting in the observed electrical shorting (sparks and slow running).

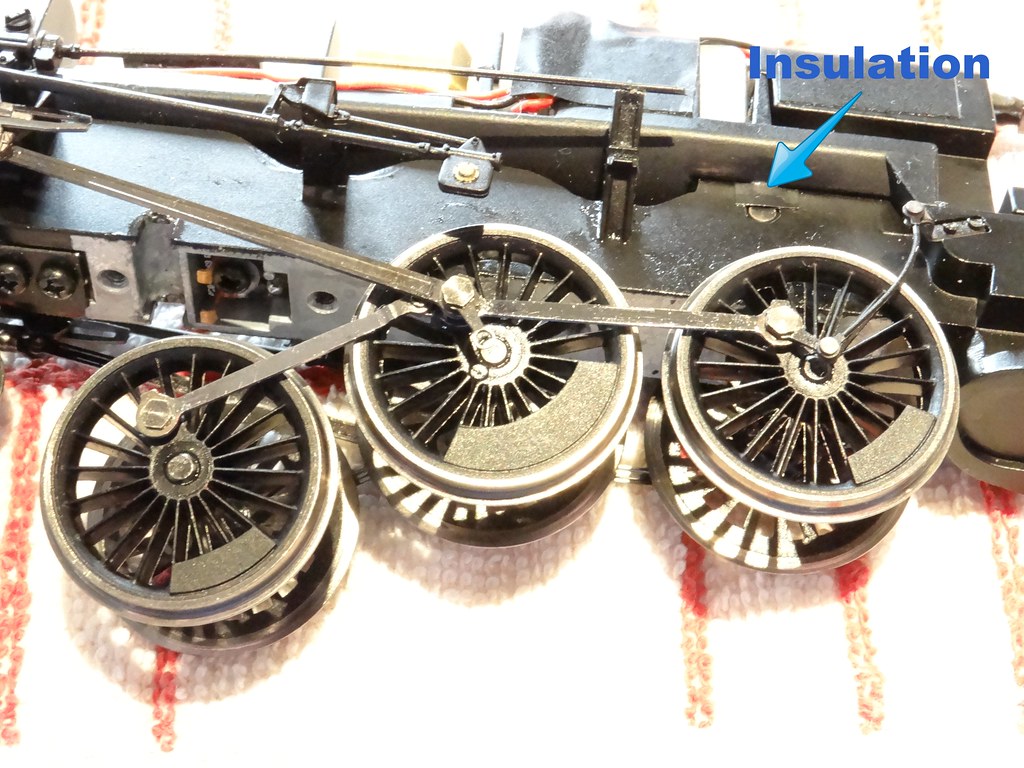

Insulating patch! (and jointed roads)

The quick fix was to cover the unpainted metal with some insulating tape. There is a lot of lubricant at the location so perhaps not a permanent fix. Plan B will probably be a coating of black paint. (I had a similar problem with a Hornby Dublo 8F where I fitted larger diameter metal rimmed wheels to the pony truck only to find that the flanges would occasionally contact the metal chassis shorting out the controller and bringing the engine to an abrupt stop.) In the longer term I guess I could dismantle the engine and grind off the protruding metal so that the bare face was recessed.

Current collectors

A second issue that I have noted relates to the means that Hornby have adopted to take the electrical current to the motor from the wipers on the wheels. On two occasions I have reassembled the engine, put it on the track, only to find that it was completely ‘dead’. On both occasions I had the wheel sets out and in order to do that I had removed the bottom plate. There is a lot of lubricant around the axles on my model and all that I can think is that this was finding its way on to the contacts labelled A and B in the picture above. Certainly cleaning these contacts before refitting the bottom plate brought the engine back to life.

Fluted or solid?

Other members of RMweb had suggested replacing the DoG one piece coupling rods with the jointed spares for Britannia. That seemed an easy fix. I would buy the necessary spare parts. From the Hornby Service sheet for post 2008 loco driven Britannias the relevant Spare Part is No. X9599. However on arrival I noted that the Hornby spares are fluted rods not solid as on DoG (or on any of my loco driven Britannias). There are plenty of pictures of DoG on Flickr, some from the 1960s and lots in preservation. These confirm the rods should be solid. Tracking down pictures of Britannias is also easy. The official picture for 70000 shows the engine with fluted rods. However subsequent ‘in service’ pictures from the 1960s and in preservation show solid rods – as fitted to the latest Hornby models. Perhaps there are some other Hornby spares which I should have purchased? However I like a challenge so the fluted rods were dismantled, reformed and fitted to show the solid side outermost.

Is there a difference in performance now that DoG is fitted with jointed rods? Subjectively I would say it runs more smoothly – although my model still seems to find all the humps and bumps in my trackwork. Quantitatively with the jointed rods fitted my Gaugemaster Controller had to be turned down a full notch to match the speed with the solid rods – so perhaps much less internal friction. The same was true when coming to a stop using the Inertia Controller – with the jointed rods the engine ran on much longer - again suggesting much less internal friction.

For interest there are two HD videos on YouTube

One with

I have to say perhaps not a great deal of difference – but it did fill in a rather wet Saturday.

The pictures above on the Hornby boxes are quite revealing. DoG (top) is shown correctly with solid rods – but look at the dummy joint on the firebox section – that is not how my model was assembled. The picture for ‘Oliver Cromwell’ (bottom) shows fluted rods which is incorrect as both prototype engine and model are fitted with solid rods. How do Hornby manage to get these things wrong?

-

1

1

.thumb.jpg.60c53fcbcaa34017b05b8919d1a9e6d2.jpg)

22 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now