Moving to P4 (Post 8)

Thanks for your replies. ![]() Am taking it on board.

Am taking it on board.

I've had a fiddle this afternoon and have got a bit further, but as is alot of this I'm sucking it and seeing.

I'm probably doing this all wrong but if I'm doing it wrong then it seems to be working so I do not know!

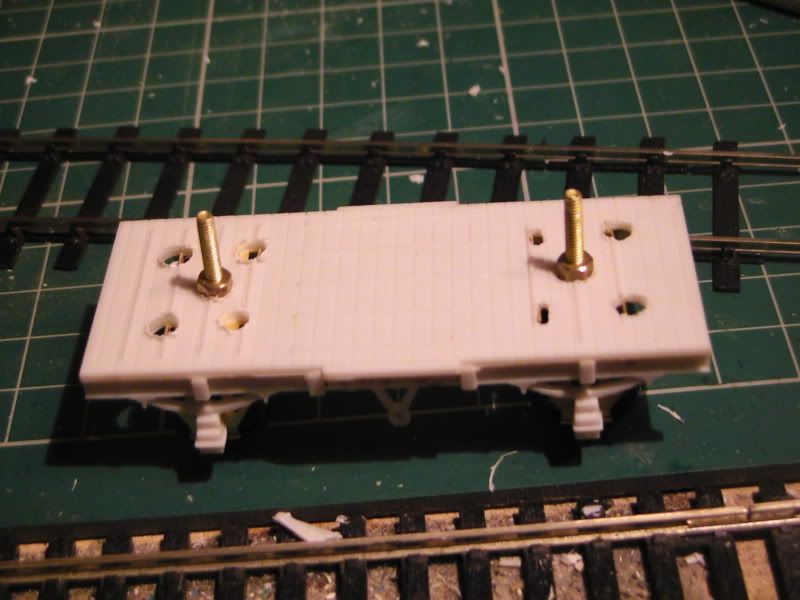

This looks horrid I know, amazingly crude.

The outer uneven holes are for the tabs in the etch to go through. In hind sight it would probably have been better to file them off but I'm unsure on ride height. I did leave them where they were and packed the etch underneith with plastic card but this was too high a ride height, since popping them through these holes it seems about right, I used my pin vice as a weight and the chassis depressed about half a mm and looks right. I think. Also the screws arn't through the hole evenly and if I was doing a 5 plank wagon this would be unnacceptable but as it's a cattle wagon and a test I'm not too fussed. I'm open to ideas. ![]()

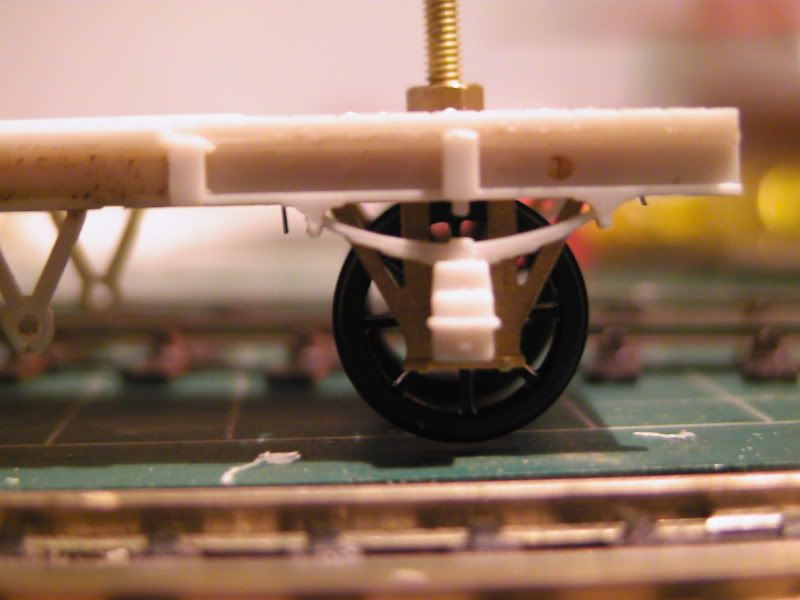

This is how it looks before a little wight depression, I think it's fine, looks better when it's dipped a tad. I'm guessing add 25 grams of lead to each etch underneith? (as long as it oens't foul the spring or axle

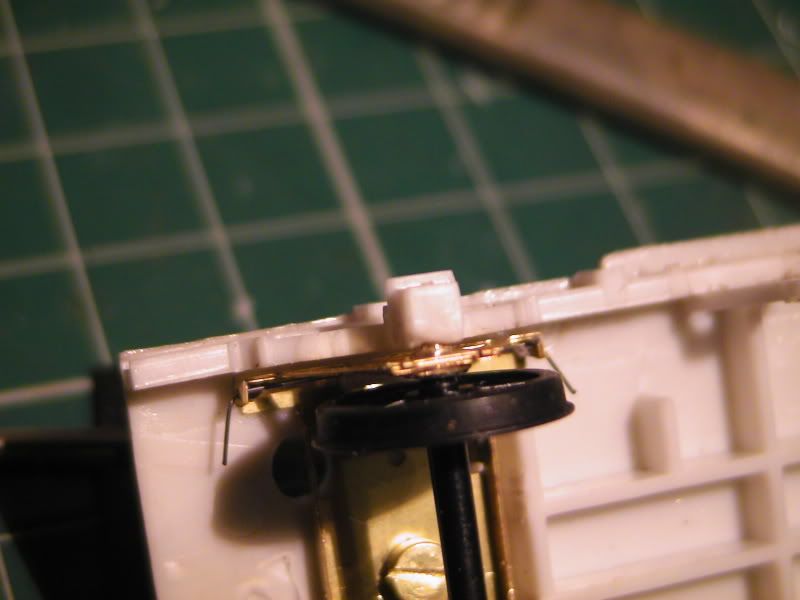

Here the brass W Irons push up to the plastic axles ok but are currently sprung away a tad. This sems to be a matter of messing about more than anything, but is the gaps between everything excessive?

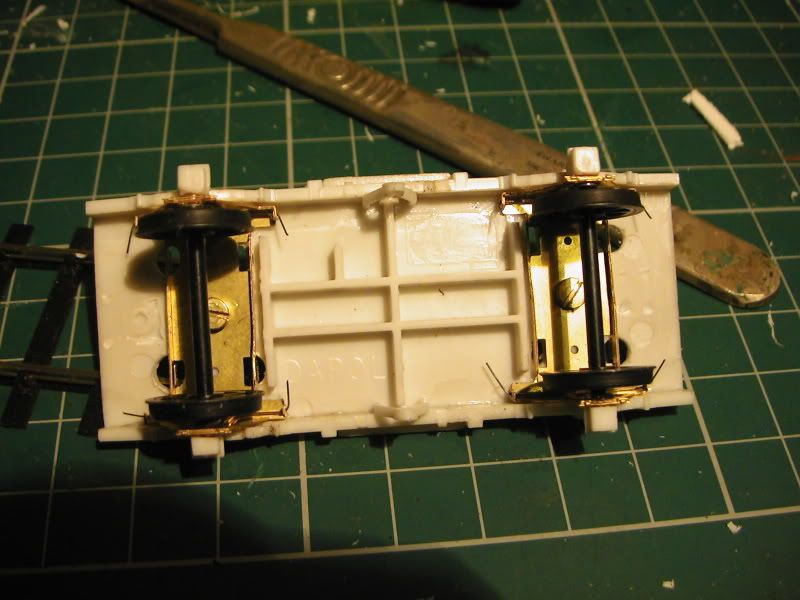

General impression.

I haven't modded the axleboxes or springs or moved them, cut them etc. Might do later but currently think they ok as is.

One thing I really do need to know is how to tell if the wheels are all square to each other etc etc. Currently it's just been a game of tweak and roll. Rolls fine on my straight and bendy bit of track I made but I guess I won't be able to tell until it goes through points. Still waiting on that point blade in the post. I suppose it doesn't help in using a screw in the middle that can pivot either but as I say, I don't really know what I'm doing! it does seem to work ok so far though.

?

-One thing I've noticed since taking thee pics is that one axle seems a tad out on one end compared to everything else, yet it seems to work fine as above. Been tweaking but can't seem to solve the reason or solution.

3 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now