-

Posts

527 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Exhibition Layout Details

Store

Posts posted by Gallows Close

-

-

Is it the photo angle Brian? But the wheel on the centre axle appears flangeless on the big gronk.

Lovely modelling as usual,

Chris.

-

Now that does add atmosphere Alex. Really nice!

Chris.

-

Hello RM Webbers,

I have a bit more progress with '132 to show, She is painted and lettered now, with just the cantrail stripe to finish round the cab tops, and then she's off for a good weathering. This particular class 31 had a three piece snowplough at one end and the centre part missing at the other as well as having the RAILFREIGHT logo on one cabside only - all faithfully recreated. When I weather it I'll mask off the spot where the missing logo once was to keep the paint fresher, just as on the real machine.

As you can see, Im enjoying this one!

Hi Alex, I'm sure Hornby will turn one out in RFG almost as soon as the last bit of paint is dry on mine - but at least I can be fairly sure they'd never do a bucket like '132 - She'll be unique I reckon. If you do a model of 31199 I sure it will look most excellent at Boxenby.

Cheers,

Chris.

-

1

1

-

-

Hi Alex,

Your walls are really coming along nicely - Just looking forward to seeing them with a bit of Toton style dirt and soot now.

Cheers,

Chris.

-

Hi Alex and Phil,

Thanks for sorting out the link - Top footage. It is nice to see the colliery wheels turning as the loco runs round it's train.

Speaking of locos I've been getting on with a project I've had in mind for some time. Here is a work in progress of my class 31, 31132 in Railfreight grey (no stripe) with snowploughs. It should look nice on a short rake of HEAs.

It is based on the Hornby class 31, and as you can see, I've dual braked it and put the m/u sockets in the correct places as well as fitting the ploughs. The ploughs themselves are Bachy ones. There is just the window black to add paint wise, and then its transfers and a good dose of grot. The 31's were always filthy.

Cheers,

Chris.

-

3

3

-

-

Hello all,

Many thanks again for the comments, they do count towards my modelling morale. This might be the last update for a bit, what with the Easter break approaching. Mrs. GC has organised a trip for us on the sleeper from Amsterdam to Copenhagen. I'm a little bit worried as apparently they do not attach the bar car until we reach Hamburg....

Found this great video on YouTube last night which I thought you might appreciate as the start is filmed at Easington Colliery and it includes a couple of nice views of the headstocks.

Oh and some Grid action too!

Nice find Alex, do you by any chance have the link as I cannot find it myself?

Cheers,

Chris.

-

Hello All,

I'm pleased to report that Arthur has made it to the top of the downcast headframe. He's just to the left of the sheave admiring the view north towards Fitzwilliam village.

The steps and handrails all came from the etch, however the back-scratcher from the inspection platform down to the top step is sctratch made from brass..

Cheers,

Chris

-

2

2

-

-

Hello RM Webbers,

Activity at Kinsley today has centred on making a start with the handrail etches. There's quite a bit still to do, but I've attached a couple of photos of work so far. Arthur Scargill made only the first half dozen or so steps before he ran out of breath...... More photos and progress soon.

With the layout set up I recreated the short period where the class 90's were regulars on the ECML. 90018 propels a Leeds - King's Cross IC 225 set past Kinsley as a class 101 set heads north. A class 37/7 is in the colliery sidings.

I also decided to give the class 70 some work. There are two shots of it on a loaded service leaving the mine branch.

Thanks for looking in.

Chris.

-

4

4

-

-

Thanks Wal,

I know Daw Mill. I have also been very lucky to have been underground in Trentham and Silverdale Collieries in the Staffs coal field before they shut.

i worked down a pit called the Dexter , it was in Hurley Warwickshire.

Didn't Dexter shut sometime in the late sixties? Bet you've some tales from there! Thanks for sharing.

Chris.

-

Hello Arpley,

.... nice to see a 70 as well. Do you plan on getting some HHAs for it?

Thanks for your comment. As it happens I have a rake of 18 HHA's - I'll post some pics up if the weather stays good this weekend.

There is also a rake of 36 HAA's, I'm working on some HEA's and I'd like to investigate a rake of CAWOODS containers in time. I need to research these futher though.

There is also a rake of 36 HAA's, I'm working on some HEA's and I'd like to investigate a rake of CAWOODS containers in time. I need to research these futher though.Cracking work there Chris,reminds me of when i worked down the pit as a lad.

Thanks Wal - which pit?

Hope to post some more progress soon,

Chris.

-

Thanks Chaps!

I'm really sorry Ants, but I have overlooked replying to your message. I hope I can make amends.

Looking good I like the Colliery tower did it take long to build? Do you have a track plan?

Below is a sketch of what I'm trying to achieve. The board with the rapid loader on is an aspiration at the moment, but the rest will be built during phase one. The headgears have taken around ten hours each to build I reckon.

...you've put a spanner in the works because now I want a coal mine with 56's n MGR's! As if it wasn't bad enough that I'm off for a weekend at the pontypool and blaenavon railway this weekend, which I'm sure will lead me to the Big pit for some photos.

Thanks for your message Lee. If you do get to Big Pit I'd be delighted if you would post some photos of your visit - especially any photos of the mining equipment.

Best regards,

Chris.

-

1

1

-

-

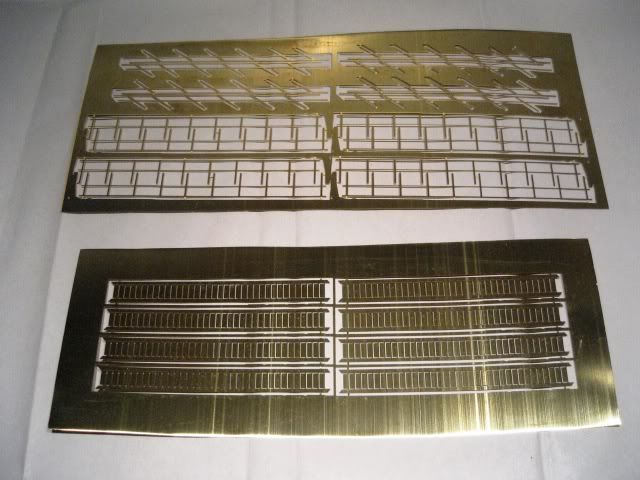

Hello RM Webbers,

Today a rather nice packet of shiney brass parts arrived at Kinsley. These will enable me to make the steps to the winding sheave inspection platforms - hopefully this weekend I'll get chance to install them, but for now here are two of the etches. You can see the steps on the bottom etch and the handrails on the upper etch.

Kinsley is intended to be set during the British Coal era - meaning 1987 to 1994. This gives me lots of scope to run my late BR era stock - but sometimes this is not enough, and I give in to more modern temptations. Below you can see the first visit of a class 70 at Kinsley.

70006 runs north from Kinsley back to Midland Road.

Hey ho it's all fun at the end of the day,

Thanks for looking in,

Chris.

-

4

4

-

-

Hello Ron,

There is a phrase in one of your posts a page or two back where you say "I'm no bridge engineer". Well - I beg to differ. This reminds me of all those time I used to try and build impressive bridges and the like with Mecanno, the trouble was I was unsuccessful - but you on the other hand seem to have it just about right. This is absolutely brilliant stuff, I'm only left wondering where on earth you will park this construction.

All the best,

Chris.

-

Hello Chaps,

Thanks for the comments and feedback.

....thou it sounds like a class 60 ticking over only joking there is one somewre near by thou

I think there was a class 60 ticking over in the sidings that day! I'll dig out some more photos, and post them up.

Thanks again,

Chris.

-

That is just how a Grid should be Brian. Very nice indeed.

Best wishes,

Chris.

-

Hello RM Webbers,

A bit more progress to share at Kinsley today. I have largely completed the upcast shaft and installed it alongside the downcast shaft. The upcast headgear was airtight to stop the powerful ventilation fans from short-circuiting the air supply - instead circulating it down the opposte shaft and through the workings. This is why it is enclosed. The pit bank building will fill the bit below the cladding. In the coming days I will receive a set of etches to enable me to make the steps up to the winding sheaves, and the handrails to go around the inspection platforms. It should look good.

I have also made progress on the building you see inbetween the two headgears. This I'm lead to believe was a water tower. I'll post more on this interesting building in due course.

Once the headgears are complete I can start to focus on the engine house. I have decided that this building will be built around a wooden frame for extra durability. This building will be a biggie at 27" long.

Also arriving at Kinsley this week was a trio of 37/7's. One of the three sits below.

With the sun out, it would be rude not to play, so here goes....

Thanks for looking in.

Chris.

-

6

6

-

-

Hello Alex,

I do like the progress, the buildings you have comissioned are really worth the investment, and also stand as an inspiration to us. On the traction front I like the class 58's lurking in there - how many do you have now? And I don't know about you, but I'm hoping Hornby bring out a Railfreight grey (no stripe) class 56. A couple of those wouldn't go amiss in your shed, and also on my layout......

All the best, and keep inspiring,

Chris.

-

Hello RM Webbers,

A quiet day in the week allowed me to get out the Meccano. After a bit of trial and error, and a couple of prototypes I have made a winding engine to power the first set of headgear. It was quite satifying seeing the colliery wheels turning for the first time. It uses a small gear box, Meccano motor and is run from a Gaugemaster controller.

Click thephotograph below to see the video of the headgear in action - can't work out how else to do it at the moment.

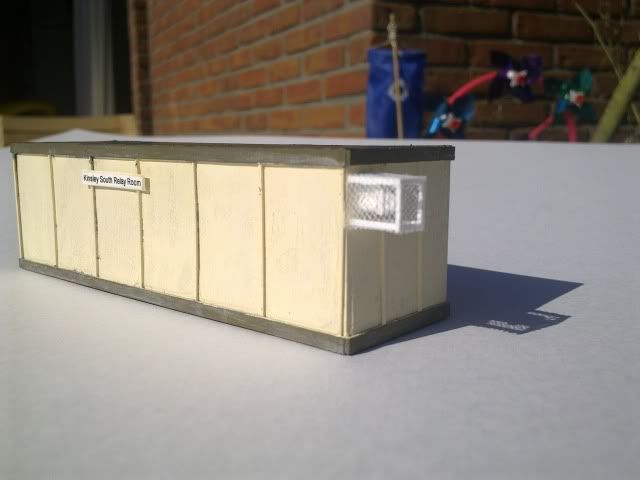

This weekend I have also managed to finish off my little relay room. This sits along side the signal box to handle the extra interlocking installed when the line was resignalled and electrified.

The air-con is made up from a few bits from the scrap box, and the warning signs have been printed off on the colour printer.

Cheers, & thanks for looking in,

Chris.

-

2

2

-

-

Hello RM Webbers,

Now that the weather has perked up I have had more enthusiasm for modelling. Thoughts have turned to creating a little scenery. In the Doncaster area the coal measures are overlain by Magnesian Limestone, and so I decided to try and reacreate a limestone cutting at the north end of the layout. The Magnesian Limestone forms a narrow north/south oriented strip of undulating land on the eastern edge of the Pennines overlooking the Vale of York - The rocks are of Permian age. Outcrops of Magnesian Limestone can be seen for example in the Don Gorge near Doncaster. Just for interest's sake the depth to the Barnsley coal seam in the Doncaster area is some 680 meters. Anyway, that's the geology lesson over, now to the model.

I decided to recreate the rock wall with ceramic tile adhesive. This was spread on to the cardboard framework and smoothed in to place. Whilst it was drying I scribed the beds of limestone on to the adhesive with a section of cut down draught excluder.

The rock face then looked like this...

A bit more work, and it now looks like this...

I think there is a small amount of weathering to be done to highlight some of the craggier features, but I hope that it looks something like.

Whilst the boards were out I took advantage to test run my Airfix/Mainline(!) now DCC class 56 in banger blue to put the layout in to '80's mode. Enjoy!

Thanks for looking in, and please give your feedback on the cutting...

Cheers,

Chris.

-

2

2

-

-

Hello Hugh,

Thanks for your comments. That must have been around 1983 when the NCB decided to shut the mine. Do you recall if all of the face machinery was salvaged at Kinsley Drift, or did it go the way of many others which closed after The Strike with millions of pounds worth of equipment abandoned below ground?

Interesting to note that some stuff went to PoW - do you recall what? The reason I ask is that I'm planning a stock yard on surface, and would like to know what equipment was used at Kinsley. The NCM at Caphouse Colliery have been fantastic in getting drawings of powered supports for me, and now its shearers, Doscos and the like I'm curious about.

Cheers,

Chris.

-

Hello All,

Been busy this week, but alas not with collieries

Hi Chris, unfortunately Taff Merthyr does not feature much at all. Although they mention it a few times near the start the only footage is of a pair of 37s passing by.

It is a good DVD though!

The North East one is very good, lots of Grids on MGRs!B)

That is a great shame. I'm beginning to think that TM was almost the forgotten colliery. At that time (early 1990's) almost all the mines had gone, with only Tower's future secure. I do have some photographs from the National Monuments Record of Wales showing a shale train being loaded up by excavator with a nice class 37 at the head - but alas nothing under the rapid loader. I think I'll still try to get a copy of the DVD though..... Sounds like it may be just the ticket.

Have you tried the Railfreight since 1968 books by Paul Shannon the Coal one is a great read along with all the others

No, not yet. Thanks for the tip - I'll get on to ABE Books and see what I can find. Paul Shannon, together with Michael Rhodes and John Hooson seem to be the most prolific photographers from the late '80's and early '90's in South Wales - so I'll need to see what else is out there from these chaps. Thanks again.

Looking good I like the Colliery tower did it take long to build? Do you have a track plan?

Thanks Ant,

I'll cobble together a track plan and post it up. It is a really simple layout though, just a junction and two sidings. The headgear took probably around 8 hours to actually build so far, with quite a few hours spent on research. I also made a scale drawing and a little jig to build it on, as I have two to build it should more than pay off spending this extra time upfront.

Thanks again for all the comments,

Cheers,

Chris.

-

Hi Alex,

This is turning out to be a rather special layout. I really like the way you have gone out to make (or have made for you!) bespoke parts for this project. It is an inspiration and just shows what can be achieved with a little lateral thinking.

Regarding Ixion, I have one of the limited edition models, and I'll dig it out to find out who made it. It is in green - post resoration if I remember. I do recall it came with a very nice wooden box, but it is one of those that was always destined never to be played with, sadly - but beautiful all the same. I also have a model of '106. Despite it's age it even runs quite well on DCC.

I hope you don't mind me saying, but have you considered lighting the inspection pits?

Cheers,

Chris.

-

Hello Guys,

I was watching Railfreight Today number 8? Wales last night and saw a pair of coal 37s passing Taff Merthyr,

I've been meaning to get a copy of that one, does Taff Merthyr feature a lot? Or are there only a few general views? I believe Deep Navigation is on that DVD too. What I'm after is some footage of trains loading at Taff.

I do have Michael Rhodes and Paul Shannon's 'Freight Only: 3' which features these mines, and the photos are quite poignant - almost everything in that book from Wales is gone!

One thing I must comment on is how good the OHLE equipment looks, especially as its hard to achieve the correct 'thinness' (if thats the right word) of all the wiring

Thanks for the compliment Phil, but there are people on here who can make better OLE than me

. I must sort out the tension in the catenary wire, and add some droppers and the return current wire. For this I plan to use fine elastic to achieve the 'sag' between masts.

. I must sort out the tension in the catenary wire, and add some droppers and the return current wire. For this I plan to use fine elastic to achieve the 'sag' between masts.Cheers,

Chris.

-

Hi Western,

Do you have a thread showing your pit-head gear?

They're the stumbling block for me not finishing some pit-head gear too.

PM me if you need tthe details of the supplier I used.

Cheers,

Chris.

Manchester Central, CLC & GN Warehouses & Castlefield Viaducts

in Modelling real locations

Posted

It's full. My jaw is already in there.