REAL Working Leaf Springs For Wagons P4.

Working Leaf Springs For Wagons.

I'll just like to say, I'm unsure if I'm the first to do this. Probably not yet maybe, I've yet to see a post on the subject until now so I hope so, but whatever, I'm rather happy I've managed to bring this idea into fruition.

The idea has been cooking up in my head for a good while now.

Firstly a disclaimer: Although unintentional, this post may erk Bill somewhat as the basis for this experiment is two of his spring units, and no doubt it's probably safe to say I've in this case definitely made the whole process rather complex, but never mind. ![]()

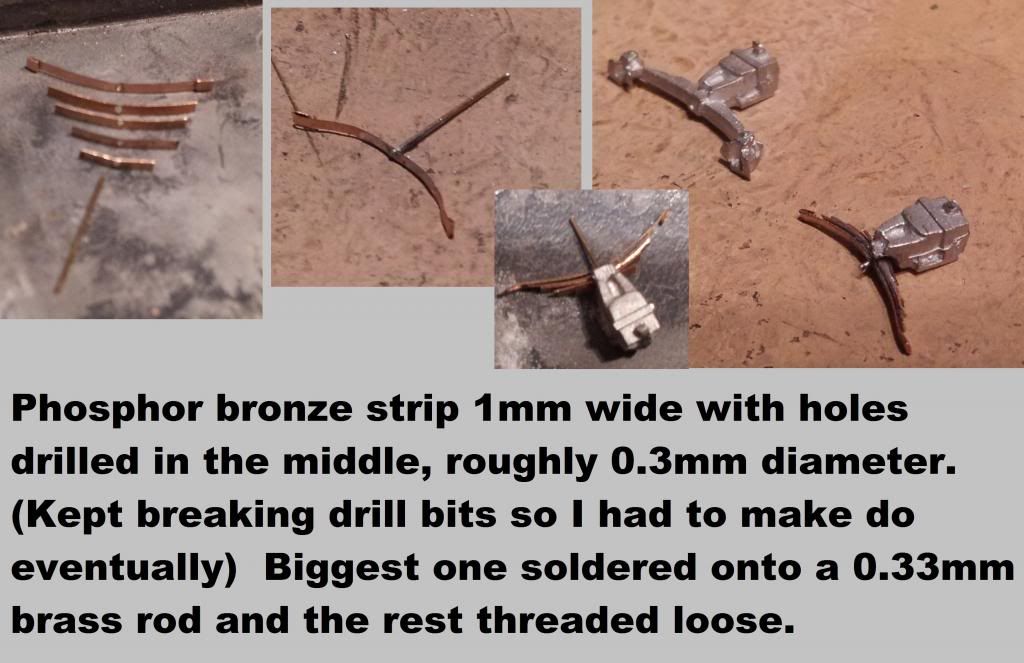

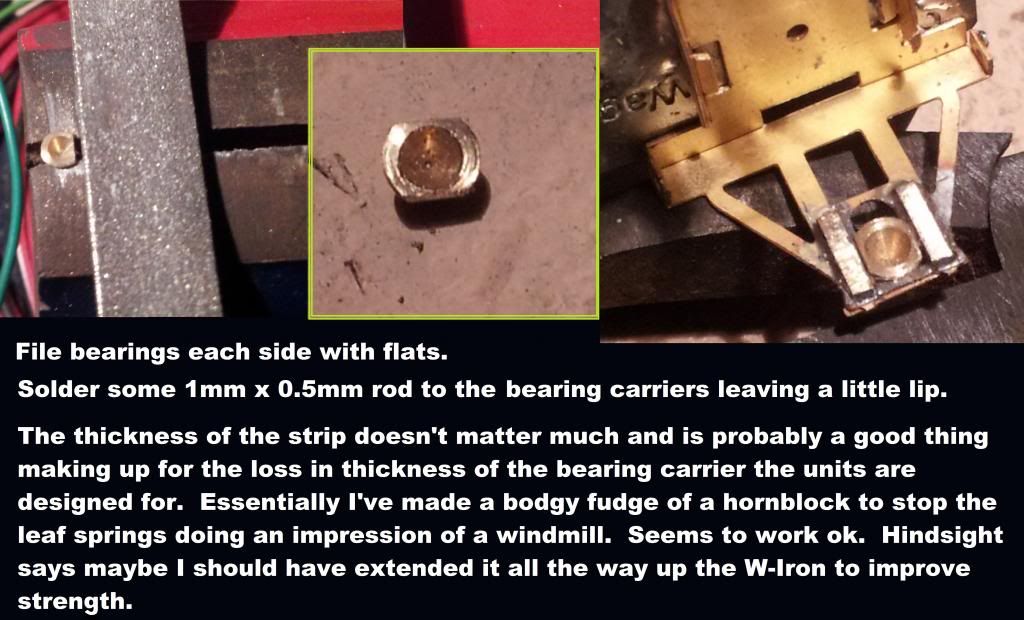

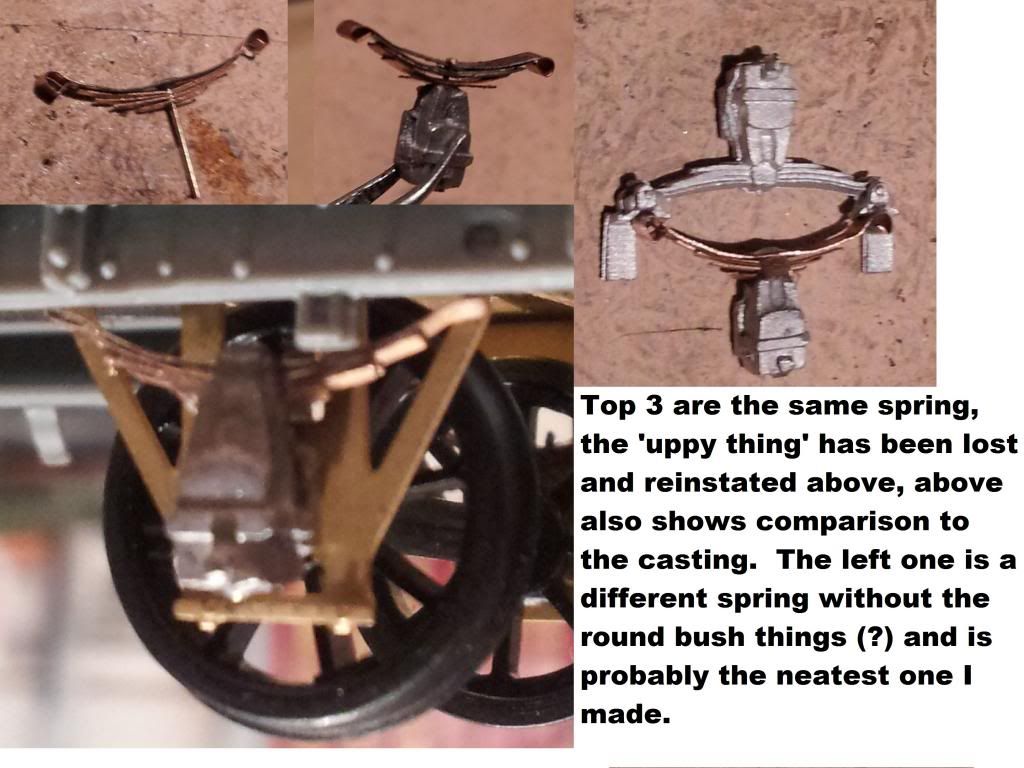

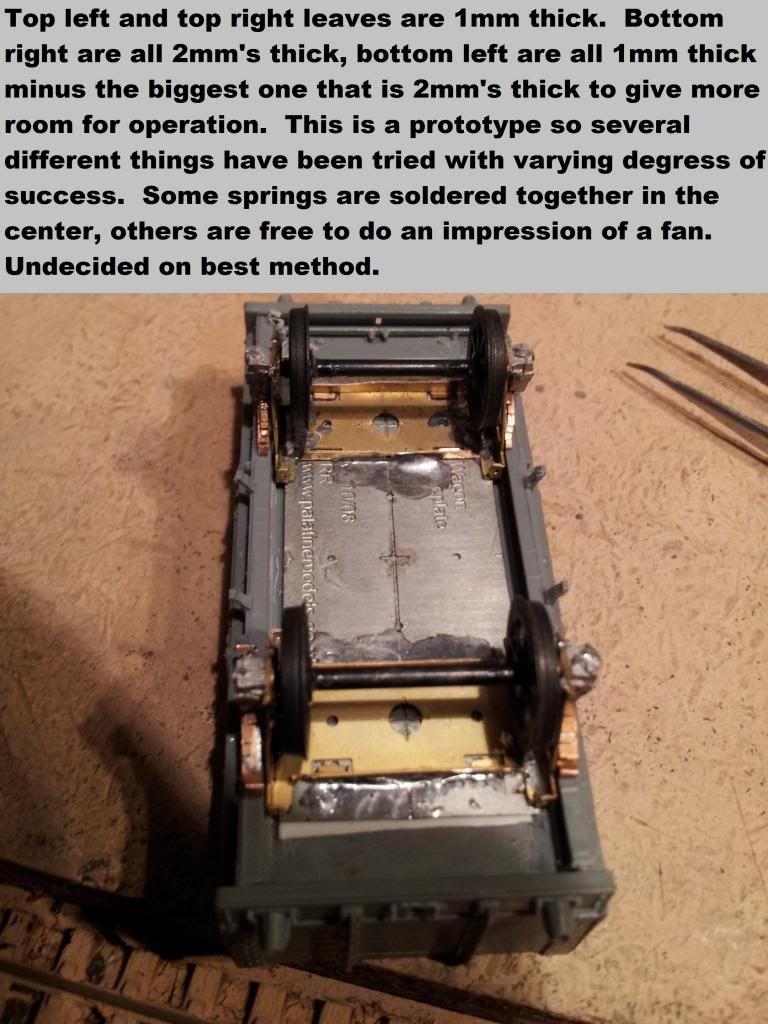

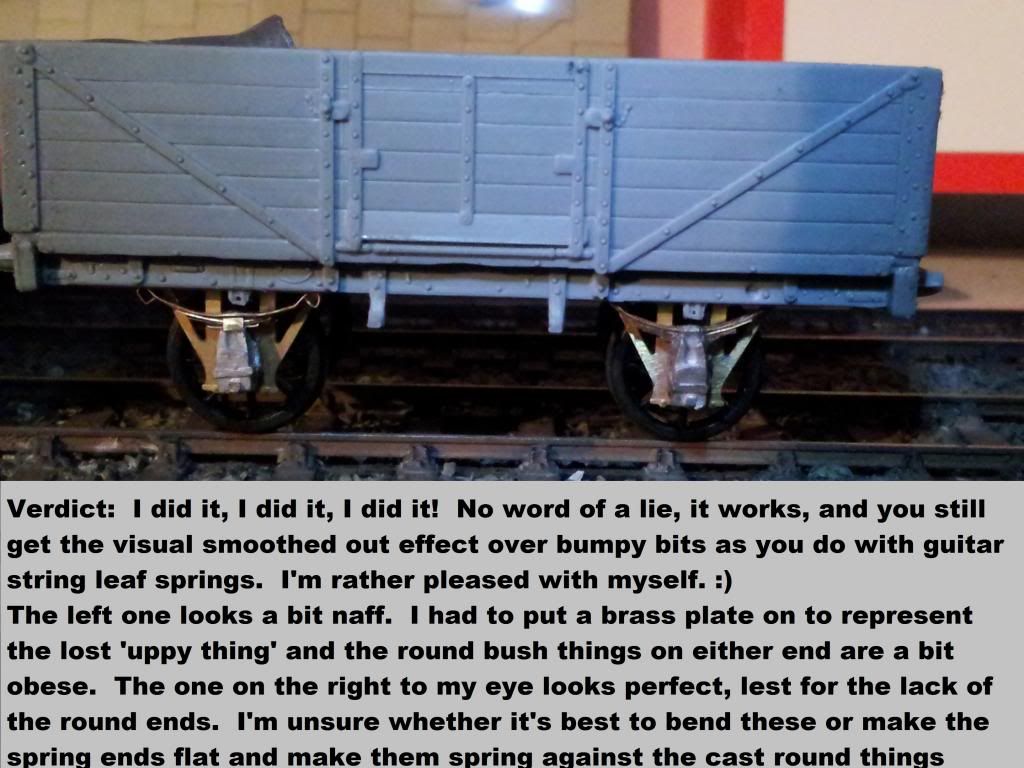

I'll be using this wagon to add etched brake gear onto later. If I am to do this whole process again I need to find a consistent way of cutting the phosper bronze strip and also consistency as a whole. The spring rate is adjusted by spring length and bend amount and how free they are to move. Fixing them obviously stiffens them a little, but not that much. So far it's trial and error but I have managed to get a fair degree of difference between the different design slants and faffing about. Really pleased with how this has all turned out, now that I've finally got it to work. Finally, REAL leaf springs to spring the wagons, not other methods pretending to be leaf springs or compensation or whatever.

Yes it's a ball ache and a faff about.

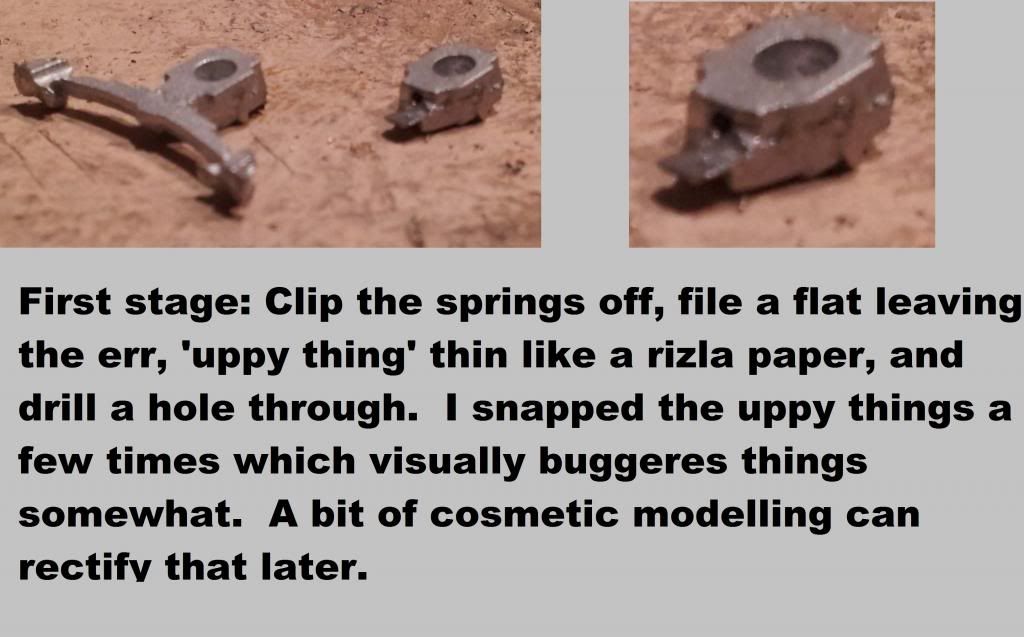

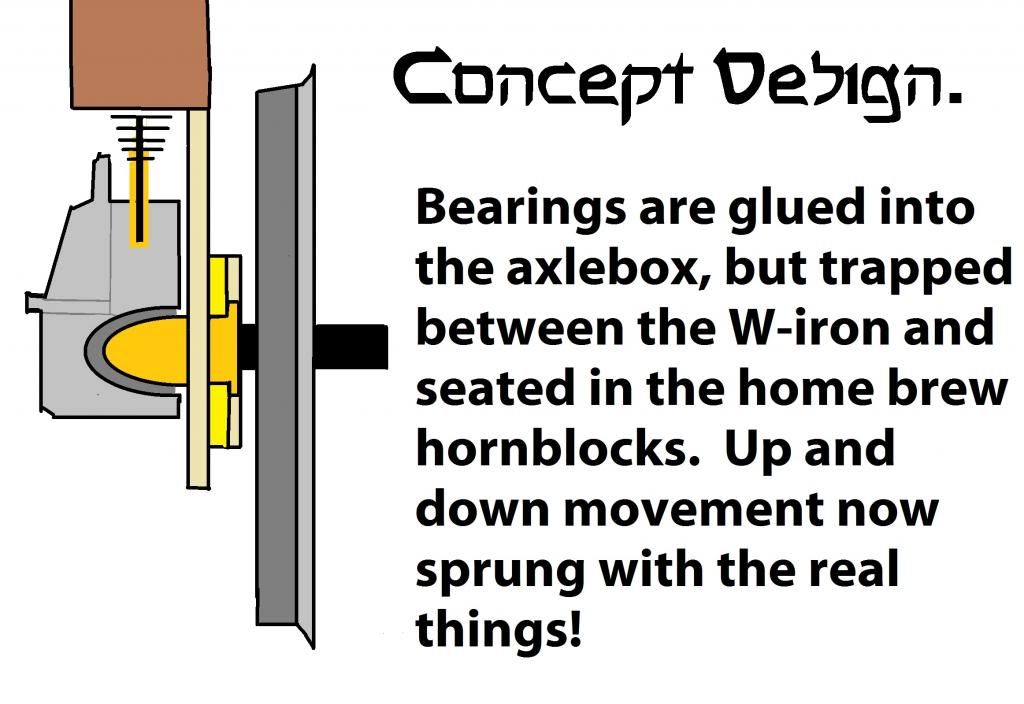

Using MJT RCH castings and a wagon kit that requires this axlebox design, I set to work on my prototype.

Visual collection.

![]()

![]()

![]()

Please comment, whether for good or bad.

4 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now