Wheels and axles – Bachmann’s early B1s

Continuing my BR(NE) saga I have resurrected a couple of elderly Bachmann B1s that have been quietly slumbering in their boxes.

Bachmann B1s – Widlebeeste and Hartebeeste

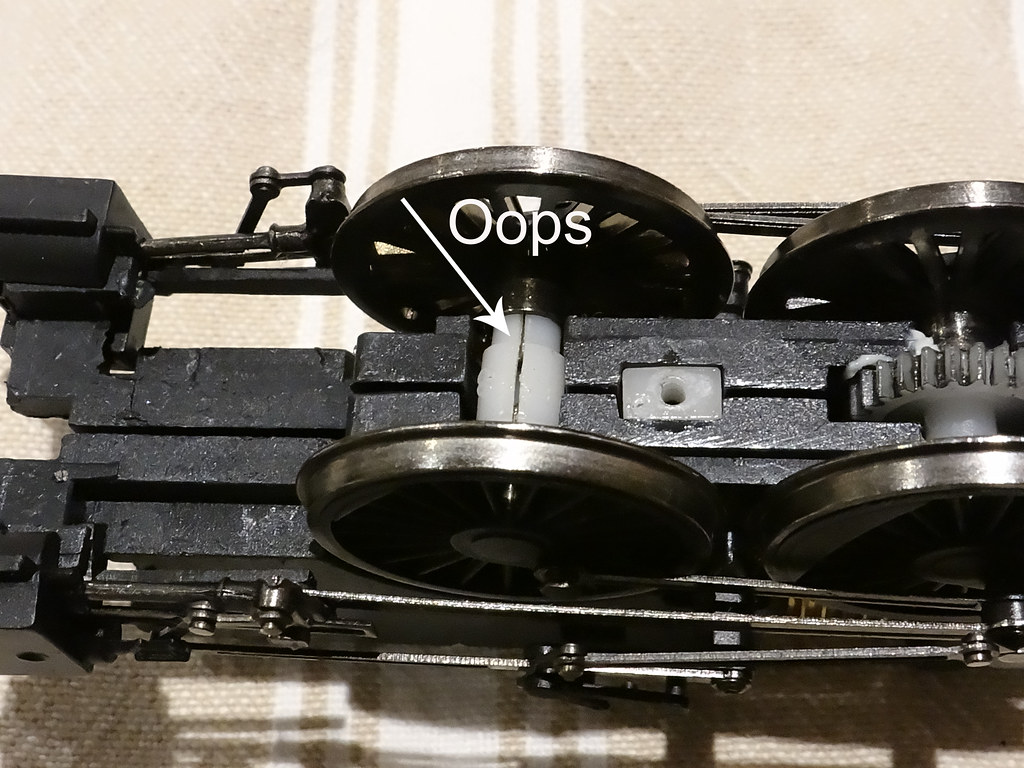

There is an issue with these particular early models and mine were not immune! For whatever reason the black plastic wheel centres expand with time and catch on the coupling rods preventing the wheels from freely turning. The affliction does not affect the centre driving wheel and rather puzzlingly it is the rear pair of driving wheels that is most at risk. Fellow modellers report that Bachmann BR standard 4MT models of a similar vintage are also affected.

Bulging rear wheel centre

Another view of the problem.

Bulging Plastic

The wheel centre appears to be a type of nylon and can be poked out from behind the wheel using a cocktail stick or very small screw driver. I think it is a push fit into the wheel casting but I cannot be sure.

Bachmann B1 rear wheel set

I guess it is possible to remove the wheel centre whilst leaving the wheel set on the engine. However I think it makes life a whole lot simpler to unbolt the connecting rods and lift out the complete wheel set.

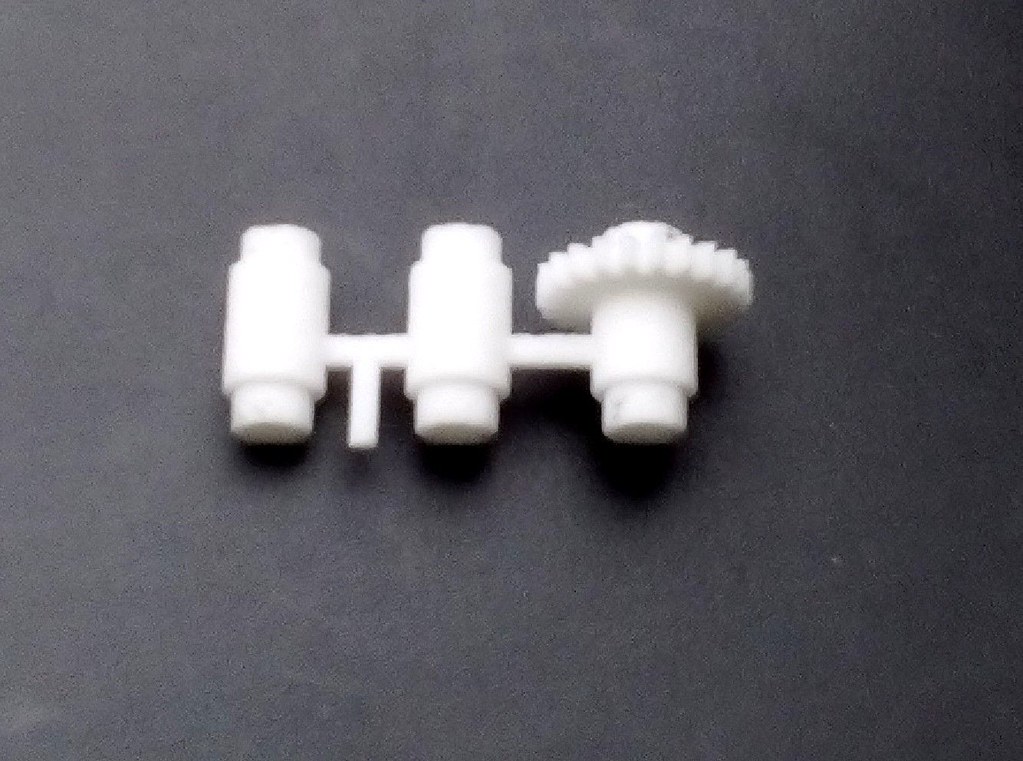

Bachmann B1 plastic wheel centre

The outside edge of the plastic inlay can then be carefully rubbed with 400 grade wet and dry (emery) paper, at the same time gently massaging the spokes back into a flat shape (a bit of warmth seems to help). The ‘nylon’ is tough and it is a slow process to reduce the diameter such that the plastic centre is a snug fit into the cast metal wheel. I have repaired two models and have not used any adhesives to hold the resized wheel centres back in place.

There is a short video here comparing before and after running:

http://youtu.be/BaXy6XUSMoA

Comments from fellow modellers suggest that the wheel centres will continue to expand with time. I have no knowledge of the type of plastic or the chemical mechanism that is causing the expansion, but given that the models are now at least 25 years old I am not expecting a huge increase in expansion over the next couple, or even the next five or more years. We shall have to wait and see!

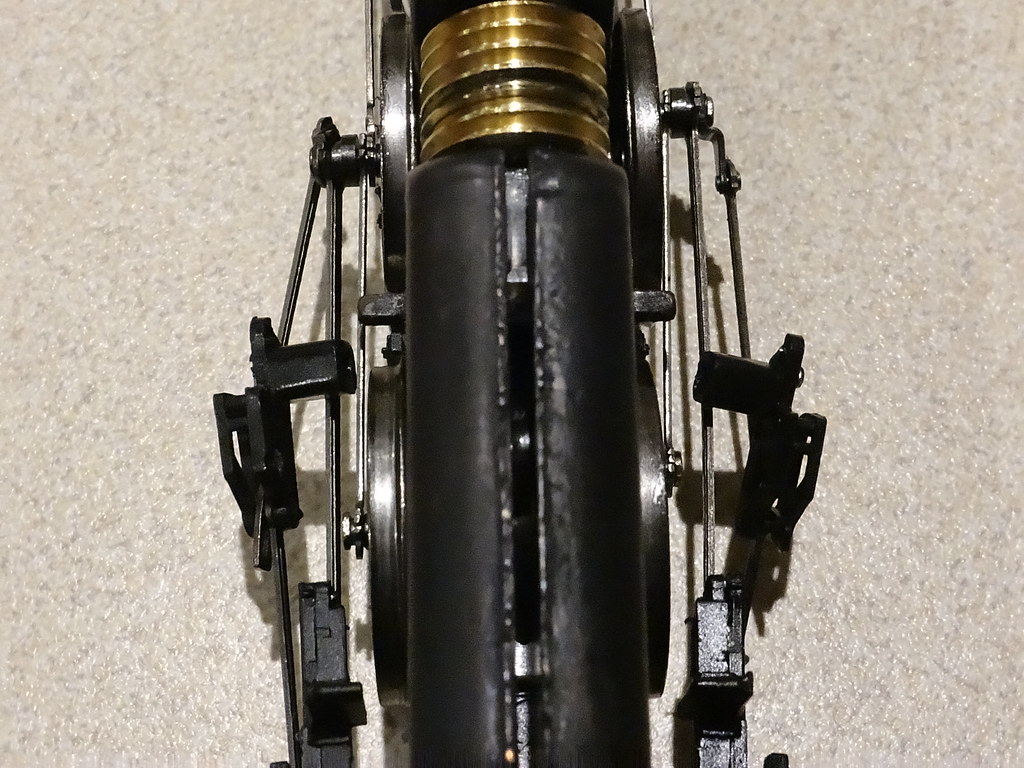

Bachmann A4 Split Axles

The other issue with these old ‘split chassis’ models is the fragile state of the nylon axles. Bachmann refer to the axles as ‘isolators’. They are a force fit onto the ‘squared’ wheel stubs and over time they will crack and break even without any use.

http://youtu.be/YWP0htE-4qM

EBay has lots of listings where old Bachmann models are offered ‘for sale’ – tested working, where subsequently it is obvious that the nylon ‘isolators’ have failed. Even in their broken state the bits of nylon will offer sufficient grip to propel the mechanism backwards and forwards in a straight line. It is only when the wheels are subjected to side forces such as when negotiating a long curve that the wheels will be forced apart – revealing the true nature of the problem.

Insulators and Circlips courtesy of Bachmann

Salvation is at hand and sets of isolators are available to purchase direct from Bachmann Technical Department in Leicester.

Why buy ‘circlips’ you ask? In order to replace the ‘isolators’ I find it best to remove the whole wheel set from the model. On Bachmann split chassis locomotives the valve gear and connecting rods are held by a circlip which slots into a groove on the end of the middle axle. Prising the circlip out of the groove with a pin or fine screw driver allows the valve gear to be disconnected, the connecting rods lifted off and the coupled wheel set lifted out from the chassis. The only problem being that the circlips are very ‘springy’ and if they haven’t shot off the model whilst being first removed, they are likely to disappear out of sight whilst being replaced. Life is too short to spend time searching for missing circlips – you just need a supply of replacements!

Bachmann B1 – spot the circlip

My experience over a number of years is that the ‘standard’ isolators fit the majority of Bachmann’s split chassis models. One exception is the old Bachmann J72, where the centre gear wheel is offset.

Bachmann J72 Split axles – from an advertisement on eBay

I have not tried to source isolators from Bachmann for the J72 but I have seen 3D printed copies offered ‘for sale’ on eBay. Bachmann isolators are ‘nylon’. I am guessing that 3D printed isolators will not be nylon and may have different mechanical properties.

Bachmann B1 – disconnected valve gear

Handling elderly models can be quite stressful! Bits just break and ping off – almost without touching! On one of my B1s the plastic motion brackets supporting the valve gear just fell off the mazak chassis casting. Luckily this is an easy repair - use a drop of Wilkinson’s super glue and push back into place.

http://youtu.be/MKVoG1SsIOI

The proof of the pudding is in the eating, and I now have two nice smooth running models.

Two Elderly Sisters

For the moment I have two good runners which can be bought for a fraction of the price of the latest offerings from Hornby, Bachmann and Dapol – food for thought?

A proper wheel centre - (19thC?) un distorted cast iron, from out of our garden

-

3

3

-

1

1

.thumb.jpg.60c53fcbcaa34017b05b8919d1a9e6d2.jpg)

32 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now