Moving to P4 (Post 6)

Whilst I await that point blade (phoned Len other day) I finally managed to work out what I think I need. Bill Bedford RCH 1907 Sprung W Irons. Might try a truck conversion whilst I wait. if you have any suggestions as to a good flat base doner (kit or RTR) please tell me.

Don't really know what I'm doing as the instructions as usual with most etches asume you have some idea what you are doing.

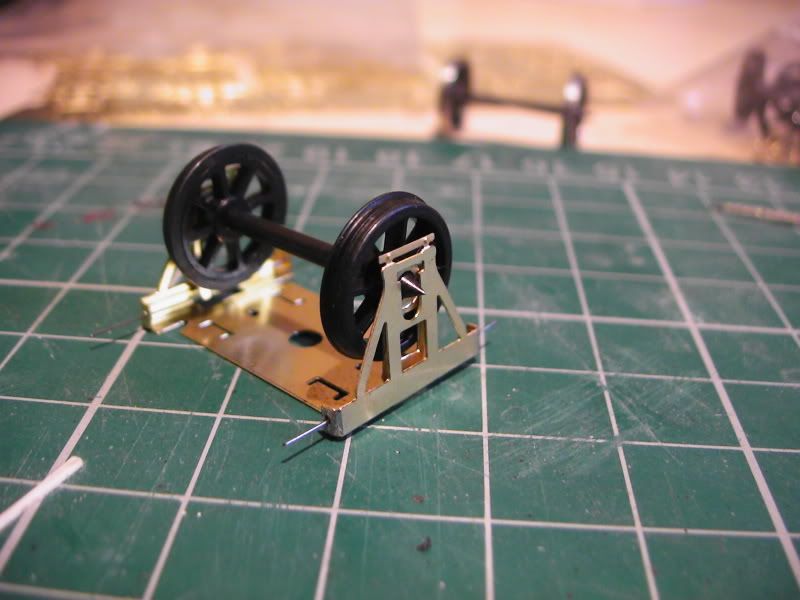

This is what I did...

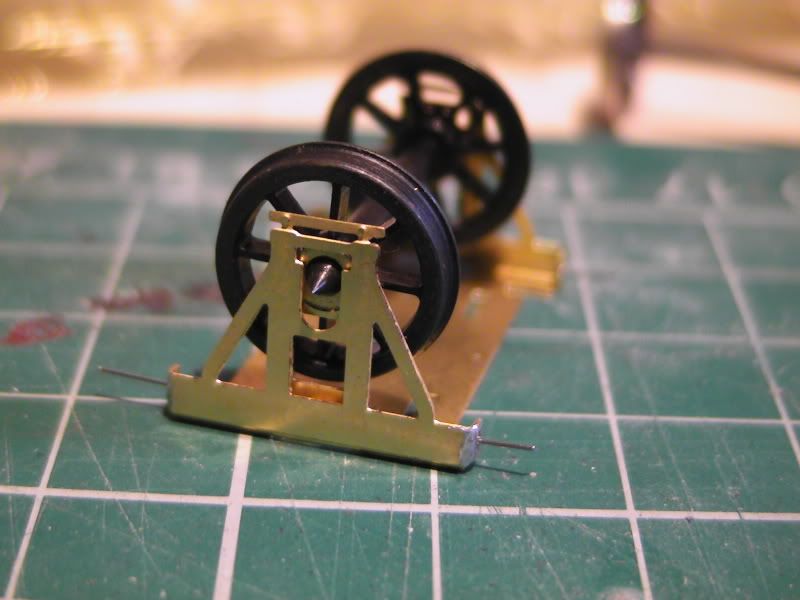

Clamped the wire in the err 'thing', ![]() then spent a while trying to get it in those 2 holes with out falling out. I did solder them in but found that that reduced the springyness to almost nothing so I cliped the wire out, filed the solder away and drilled new holes. After that I did the same again and just about managed to fit the (I think Alan Gibson - from S4 stores) wheelset inside and bent a bit of pressure in. This kind of worked and I was going to ask how to reduce sideplay, front and back play and a few other things but as I were taking these 1st 5 photographs it occured to me that maybie you need bearings (again, nothing in instructions as they assume the builder knows everything, even if it is bloody obvious!) so after much sighing I finally managed to fit the wheels, 2 bearings, 2 swinging spring things into the W irons and this solved many problems, all apart from one. A bearing would bet stuck every so often, so now I'm thinking maybe I am supposed to solder the bearings to the 'things'

then spent a while trying to get it in those 2 holes with out falling out. I did solder them in but found that that reduced the springyness to almost nothing so I cliped the wire out, filed the solder away and drilled new holes. After that I did the same again and just about managed to fit the (I think Alan Gibson - from S4 stores) wheelset inside and bent a bit of pressure in. This kind of worked and I was going to ask how to reduce sideplay, front and back play and a few other things but as I were taking these 1st 5 photographs it occured to me that maybie you need bearings (again, nothing in instructions as they assume the builder knows everything, even if it is bloody obvious!) so after much sighing I finally managed to fit the wheels, 2 bearings, 2 swinging spring things into the W irons and this solved many problems, all apart from one. A bearing would bet stuck every so often, so now I'm thinking maybe I am supposed to solder the bearings to the 'things'

Is that right? ![]()

1st 5...

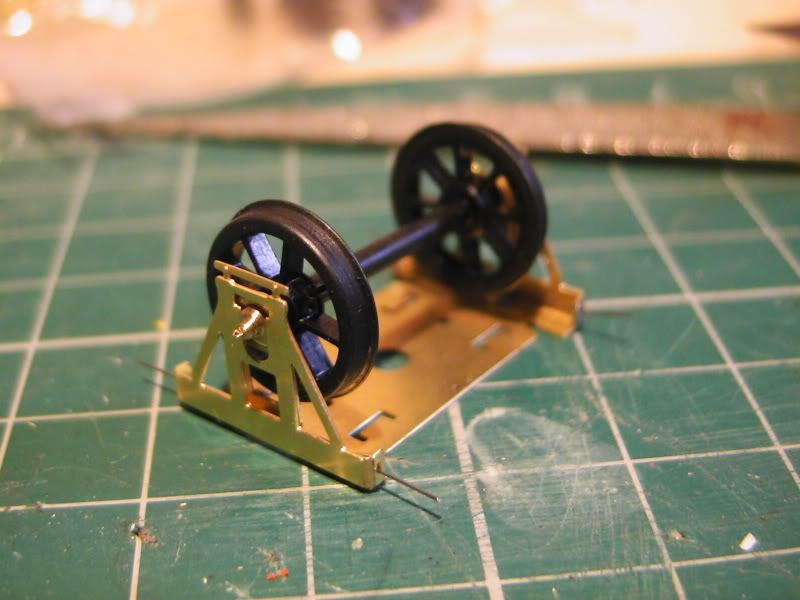

last 4, these are with unsoldered bearings fiddled in...

Also is it correct for these to be bent non parrelel? I feel such a n00b.

EDIT: I had a go at soldering them in, seems much better and easier but I stil have the problem of them sticking in the slide sometimes. I gently filed a teeny weeny non noticable amount away from the W iron slider and this seems to have solved the issue. When the springing is working is it normal to have the W irons splay sideways?

9 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now