-

Posts

381 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Exhibition Layout Details

Store

Posts posted by Beatty 139

-

-

Hi Simon

As ever your work is just stunning but would you consider/take much work to scale this up to 10mm scale and producing a set of parts I have just the ballast train to run with this already...... I wouldn't dare ask on the Western Thunder group as their a bit 1/32 biased, but some of us are still working in 'British' gauge 1

Thanks

Andy

I've not done much in the 37 recently- I did upload a 37/4 to Shapeways but it's not available for sale yet (I will re upload it so that the new Shapeways upload tool can check it).

I have started a thread on Western Thunder about some recent larger scale modelling - link below.

http://www.westernthunder.co.uk/index.php?threads/3d-printed-class-20.3329/unread

-

1

1

-

-

Hi Clive

That's how I would expect it to be but I have only seen that one surviving box as per the photograph with that kind of arrangement, but until a photo or other evidence comes to light I doubt anyone could question it.

All type 1.2 & 3 boxes use the corner posts buried in a post hole to form the foundation of the building with the flakes filling in between.

The tapering corner posts are a pain to get looking right as the only taper on the outside faces unlike a signal post that taper on all four.

Regards

Andy Mould

-

Hi Clive

I have built quite a few MR boxes now of types 1,2,3 & 4 and have been doing quite a lot of research.

The image below may be the answer to your question, the Midland didn't use foundations as far as I understand it until the type 4 signal boxes, although quite a few were underpinned with foundations as the corner posts went rotten. That has happened to the Box in the photo and Network Rail added the foundations a few years ago.

the Box in question is a 10' square ground level type 3 box and as you will see the locking room floor is suspended above the bank.

if its of any use please see the photo below as the rear of a Type 2 box.

If you need any information please feel free to ask.

Kind Regards

Andy

-

1

1

-

-

This is just work in progress

I normally laser engrave brickwork on my model buildings but for some time have been wondering if there was a better way of producing stonework other than scribing clay or plaster.

A Warley show there was tucked up the top end of the hall a sales stand for Bromley Craft Products (usual disclaimers about no connection etc) and by the second day I actually noticed it and had a nose.

Well I have just had a chance to use there stuff and had a go and this is the initial results of which I am most pleased, unfortunately it was quite cad intensive for me as they don't produce their stencils in 10mm scale so I have had to draw and cut my own custom ones for the building (NER Romaldkirk Station).

I am hoping once detailed finish painted and varnished it could be a route forwards.

I will update once I have made some more progress.

-

7

7

-

-

Just found this thread and very impressed by the content, hope I don't disgrace myself with a couple of my offerings.

Midland Railway type 4 box in 10mm scale, built for Stanley Midland layout of the Midlands Group G1MRA, including lamp room and WC.

And a almost finished NBR West Highland extension railway box, still need to do some work on this adding guttering, down spouts etc.

Both models built in laser cut ply/mdf

-

10

10

-

-

Are you sure that Walter Somers forged naval gun barrels? There is no mention of it in their official history. In both World Wars they were tasked, along with other work, with forging naval shells up to 15" diameter.

Well when I did a factory visit in the 1980's they had a Gun barrel lathe they had acquired as war reparations from WW1 at the time it was working on a secret project, odd as the drawings were laid out on the bench next to it as US Navy USS Iowa, we were told (under the counter) that they were one of the few places in the world who could still forge and machine a 16" navel gun barrel, so you can see it was no surprise a few years later when it came out they built the Super Gun.

If they were still doing them in the late 1980's I am sure they would have been doing the same during the wars, the other big job they used to do at the time we visited were submarine propeller shafts that apparently had to have almost perfect balance to prevent noise when running silent.

The Rose Gun Barrel works on the other side of the road is a mystery to me other than having found it so described on old maps I know it was a large works in later years before being converted to a trading estate. All that remains now is one building facing Somers

I would guess that the Admiralty must have had a source of local gun barrels to justify a proof testing site just outside the Birmingham area. It could be a case of putting 2 + 2 and coming up with 12 but I thought it was worth asking the question.

-

Hi

Just a question that has been at the back of my mind for a while, on the Lickey Hills just south of Birmingham used to be a Navy Gun proof testing ground, the Butts were a well know landmark next to the visitors center and were only 'tided' up a few years ago, but I am told you can find test shot in the ground.

The road to the test ground was via Rose Hill is steep and today the main A38 through Rubery that avoids it was a diversion built by Napoleonic prisons of war. it must have been some sight to see the big gun barrels being hauled up rose hill, I presume by traction engine.

The Railway element of this comes from the Halesowen Branch from and its notoriously light weight viaduct long restricted to MR class 2 goods tender engines and no bigger, Walter Somere in Halesowen and the Rose Gun Barrel works on the opposite side of Mucklows hill produced (and still did until the 1980's) some of the largest naval gun barrels in the world, both had private siding on the Halesowen Branch so does any one know if these traveled to Longbridge via the branch to then be road hauled to the proof testings site or would they travel via the main line either via Droitwich or Birmingham or even been road hauled all the way (over very difficult and hilly roads) if locos couldn't double head over Dowery Dell viaduct would they allow a loco and gun barrel?

I have read most published work on the Halesowen Railway and never read a reference to gun barrels being moved, but only found out recently what was going on up the Lickeys so I have kind of put one and one together with the manufacture and proof testing at either end of the branch.

Any ideas?

-

No problem, I'll post some pics when I get a test print.

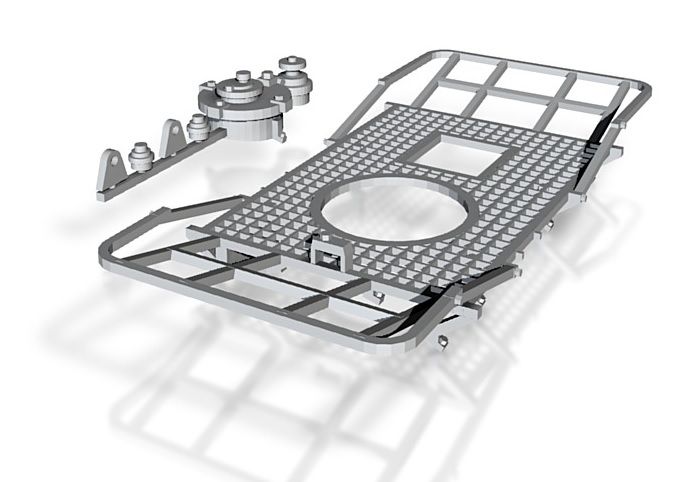

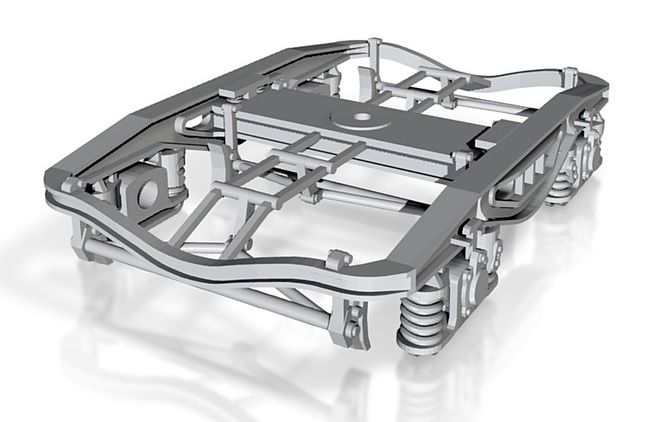

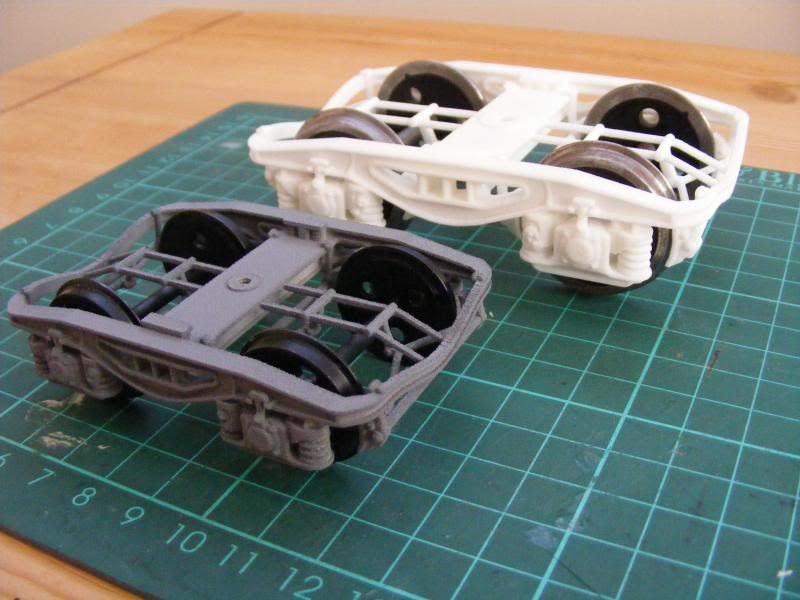

Do you know much about the wagons? I couldn't find any pics of the wagons from above so had to do some guess work from Paul Bartlett ground level pics. I ended going with the frame below but i'm not sure how accurate it is.

I've got a day off work today so I've had a bit of a catch up on modelling.

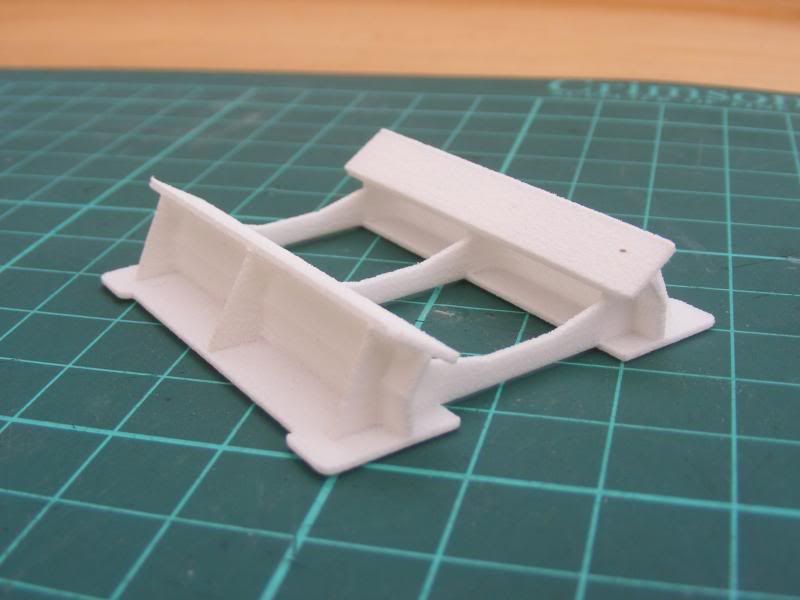

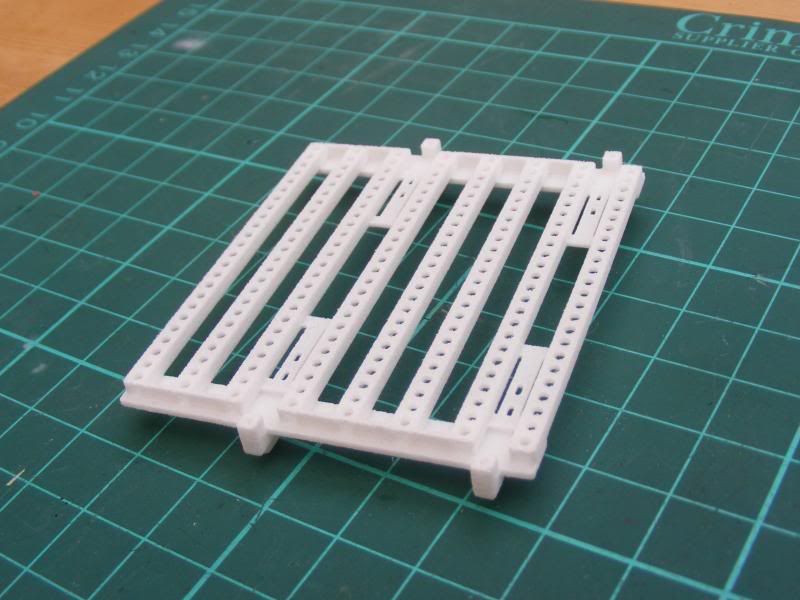

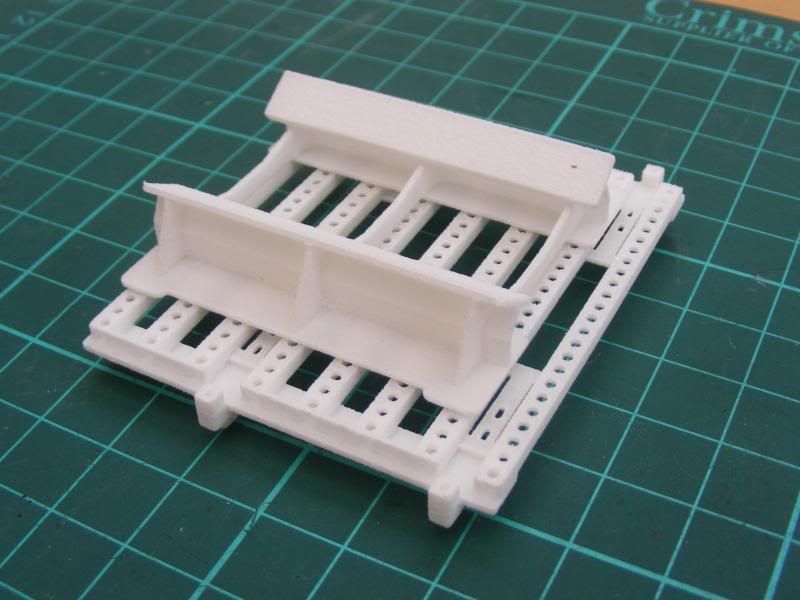

In a previous order I printed part of the deck of the BAA and a cradle as I couldn't get the whole thing uploaded correctly. These parts were done in WSF and haven't been cleaned up - I think quick sand and prime would make them look a lot better.

I was hoping today would be nice and sunny so I could do some more painting on the various 25s but it's raining.

I did give them a coat of yellow the other week to see what other work is needed.

The 4mm cab does show some small air bubbles but then when I only started detailing the cab as a test and didn't use a good casting as I wasn't going to use it on a model but I might fit it to a Bachmann shell anyway.

The 7mm 25 shell also has a coat of yellow but it's shown up a couple of problems, firstly that the area around the inside of the windows needs some more work especially the door windows and secondly that the pencil lines drawn on to line up the clips are still visible - will these disappear under another coat of yellow or will something else be required?

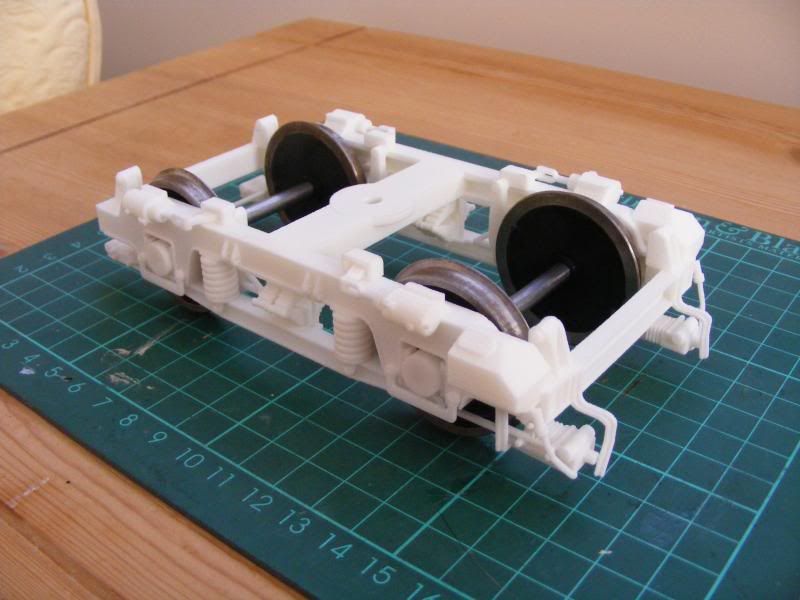

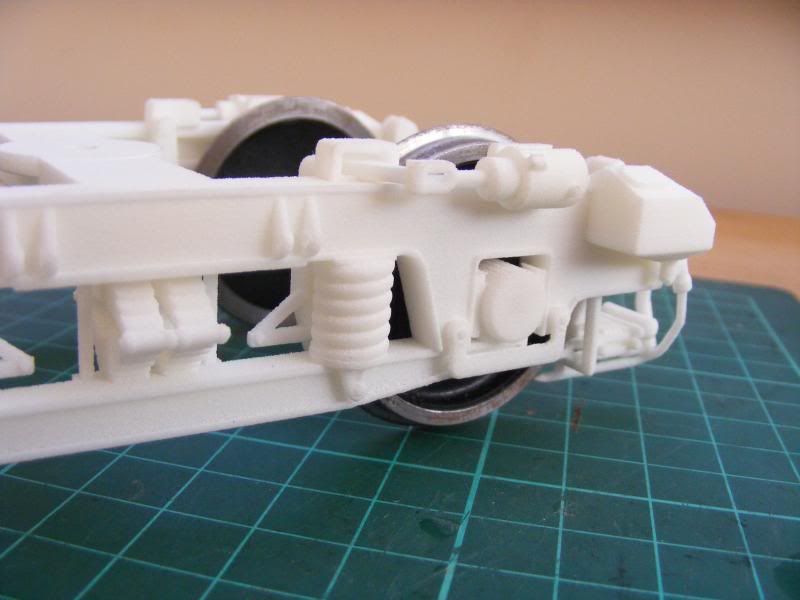

Another item printed recently is the Y25 below that I got printed in gauge 1 - 1/32 after I got some slater wheels and enlarged the 7mm version. the larger size has made the bogie more rigid and able to take more weight but I think it's still flexible enough to adjust to track unevenness (if only I had some track to test it on).

The second pic shows it next to the 7mm version.

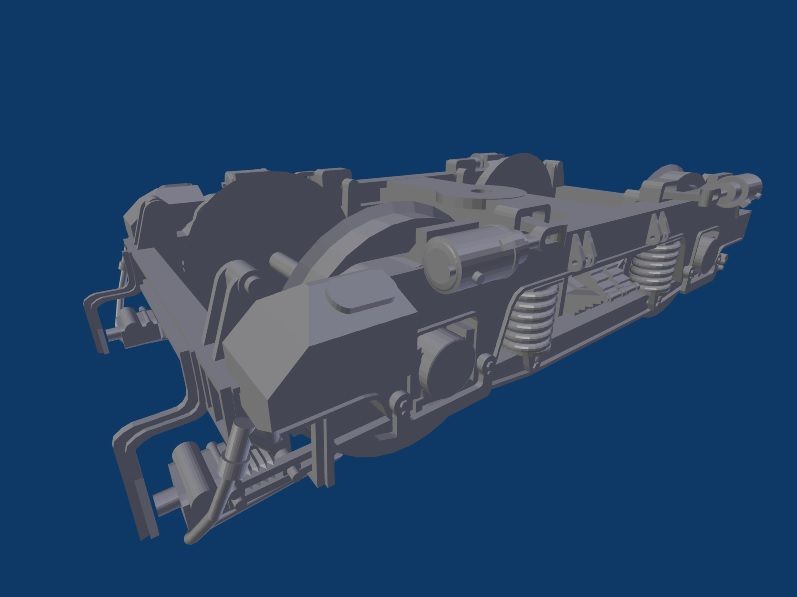

Another 1/32 item I got printed when shapeways had 10% off was a 1/32 scale class 20 bogie. This was a scaled up version of the side frame I drew last year. Like the Y25 I purchased some coach wheels form Slater's to check the fit first, I went for coach wheels as they have pinpoint bearings and the same axle size as a 7mm gear set and motor I have. I need to sort a way of mounting the motor but hopefully I can get it to work. One problem I found was the bogie was stiffer than the Y25 and had less flex as there are more parts joining onto the axle boxes which meant that it was hard to bend them outwards to fit the wheels and bearings but once fitted the wheels turned freely.

if I can get the bogie to work I might think about printing a class 20 shell.

Hi I suggest you look up the Fossmotor as sold by:

Peter Spoerer Model Engineers 'Innovators in Model Garden Railways'White Horse Works, Fakenham Road, Morton NR9 5SP

01603 260562 peterspoerer@fast-mail.net

they can also supply sensibly priced RC and battery packs.

Hope that helps, the fossmotor are a nose hung traction motor like full size and will fit in most bogies although I would suggest that 2 only would pull anything that a class 20 would ever come across in G1

Andy

-

As far as I am aware the cabinets do contain a diesel hydrovane compressor for the train air brakes required when the Hunslets were at Longbridge, it's quite a standard modification as a quick fit to industrial loco where they compressors are only sized to do loco brakes and control systems and not capable or charging train air brake systems within a reasonable amount of time. I know Wilmott brothers did the same to an 0-6-0 Yorkshire that they had on hire at the Austin.

The new Sainsbury's opened today on what was the old power hose and north works at the Austin, it was not so long ago that traffic was coming in and out of the factory.

-

if your in the midlands Chasewater has a MS&L 6W its not been messed about too much below the solebars and could be closer than the K&WVR.

-

sorry for the delay but a drawing of a shunters pole and brake stick appear in Midland Record Vol 4 page 71.

dimensions given are 5'9" long and 1 1/2 dia

-

There are some good (works or period) construction drawings for the Barnums in David Jacksons book J.G.Robinson a lifetimes work published by oakwood press.

Could I ask where you found your drawing for the LNER platelayers hut I have been looking for one for a while and I am still looking for the LNWR Webb Huts drawings.

Thanks

Andy

-

I think that 'Midland Record' has a set of offical drawings for shunters/guards tools, I will have a look through my set tonight and see if I can find them.

On the matter of brake sticks, most industrial sites would see the as a luxury with the shunters pole being used, and ending up banana shaped!

-

Hi

I have now had a mooch through my stuff and I do indeed have some Planet SCW class works drawings, the one I think would have been most useful is as ever missing but as thats the pipework and wiring layout I guess thats the one we used when doing the restoration work, and is in one of my mates lockers in 'safe keeping'

The drawings are noted as SCW Class 75Hp used on loco Serial No. 3686 onwards

I can now though confirm that the Locos have:

5' 6" wheel base

Wheels are 3' 1 1/2 on tyres

Buffer beams 7'10" wide 3' 5" deep x 1 1/4" thick

Frame channel sections 8" x 3 1/2" and are mounted 6' 3" apart rear face to face giving 6' 10" outside face to face

Face to face of buffer beams 14' 10 1/2"

3' 11" rail head to footplating

Engine Hood 3' 2 1/2" across 3' 11" hign above foot plate

Radiator 3' 1" wide over side channels 8" deep and mounted 8 23/32" from rear face of bufferbeam to centreline

As the Drawings are in 1 1/2" and 3" to the foot I can scale a lot of infomation off if someone wants something specific or even copy details such as axleboxes

Hope this helps

Andy

-

1

1

-

-

Yes, that might be an option; likewise getting it etched in brass. Might be a bit costly as a one-off though?

The only issue would be having an approprate CAD drawing, as a one off laser cut job in 1/32 ply I would have thought it would come out between £10-15, our complete Midland signal box kits in 10mm scale start at only just over £100 Your quite right about mainstream etched brass, it would be killed on price by the cost of the photo tool, but there are other ways, a single sided etch produced using the laser to cut through a mask can produce a great scratch building aid (you would still need to cut the outline) or for a simple etch like the lower parts of the box home electronic type pcb etching methods can be used with great effect.

Andy Mould

Woodbury Models

-

Yes, currently considering the options for the planking detail on the base - any suggestions gratefully received.

An ideal job for a bit of laser cutting and engraving in 1/32 ply?

-

1

1

-

-

Hi

Some years ago I owned a Planet SCW class shunter Ex Petrofina at Preson docks and restored it to working order transplanting the Dorman engine that had broken its crank with a nice Gardner 6LX. I did have some works drawings, but I am not 100% sure where they are now but I will look next time I pop into my dads where I think they still may be.

I later sold this loco to the chap who owns Titley Junction, I was only down there last Saturday and took the loco down the line for a run, I am due back soon so if there is anything you would like detailed photos or dimensions for please let me know.

http://www.uklocos.c...display&Id=3249 is a link to a photo.

Andy

-

2

2

-

-

The Van from Granville Colliery is ex Cannock and Rugeley Colliery is and now at Telford Steam Railway,

Chasewatwer also have a second much older Colliery Van thats located as a cripple out the end of the steam running shed, its known as the 'Slum' and was built by the Cannock Chase Colliery at the Plant approximatley on the site of Chasewater Heaths station.

I understand that both CRC and CCC rules requied vans to be used on the internal main lines because of the gradients encountered on the chase.

-

Hi I know that last posting on this thread was a while ago, but does anyone have any infomation on the D&L site (orignally B&V) I have had been told was known as Dock St foundry?

It was right in the shadow of the transporter bridge and I understand it was the jobbing foundry of D&L producing castings for works but not for sale.

Many Thanks

A Guide to using the Silhouette Cameo Cutter

in Scenery, Structures & Transport

Posted · Edited by Beatty 139

I have just had an issue that I cannot find noted elsewhere.

I have produced a file to test my recently purchased machine cutting out strapping for wagons.

I have produced a DXF file in autocad as I normally would for my laser, but when I open it in the Silhouette software the file is not to scale and as far as i can work out it may be treating a unit as imperial not metric.

Any Suggestions?

I should say that I have also tried saving the file from Corel with the same effect.

Regards

Andy