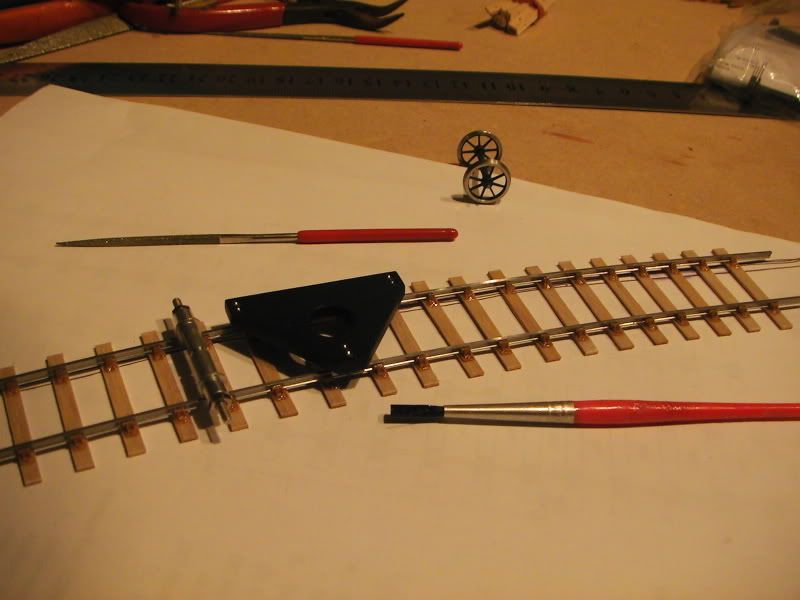

Moving to P4 (Post 3)

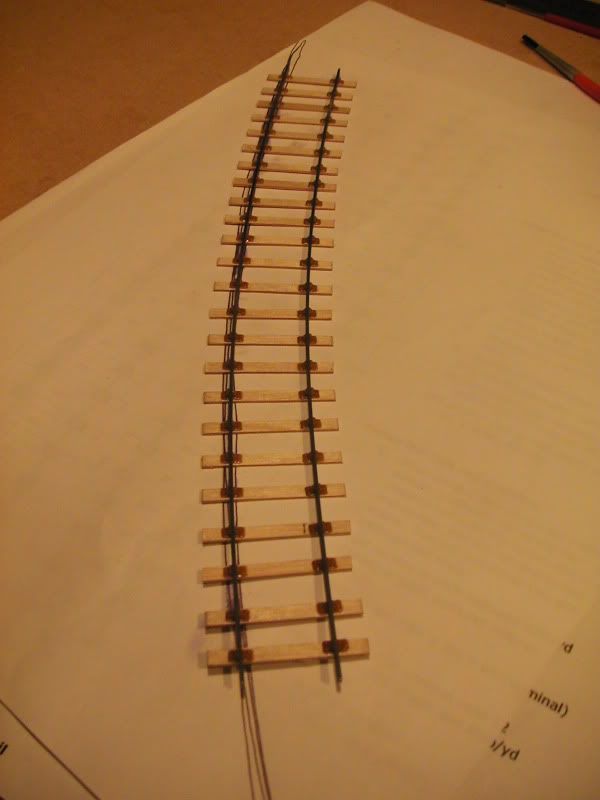

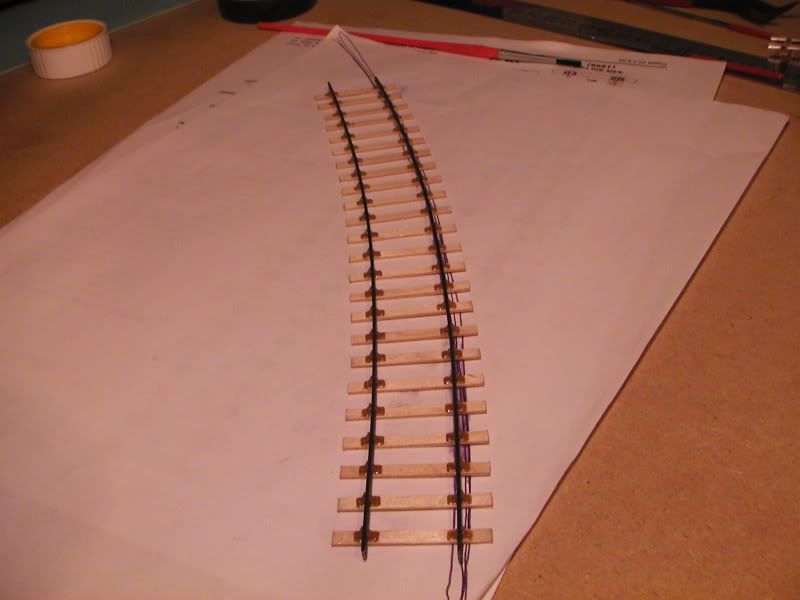

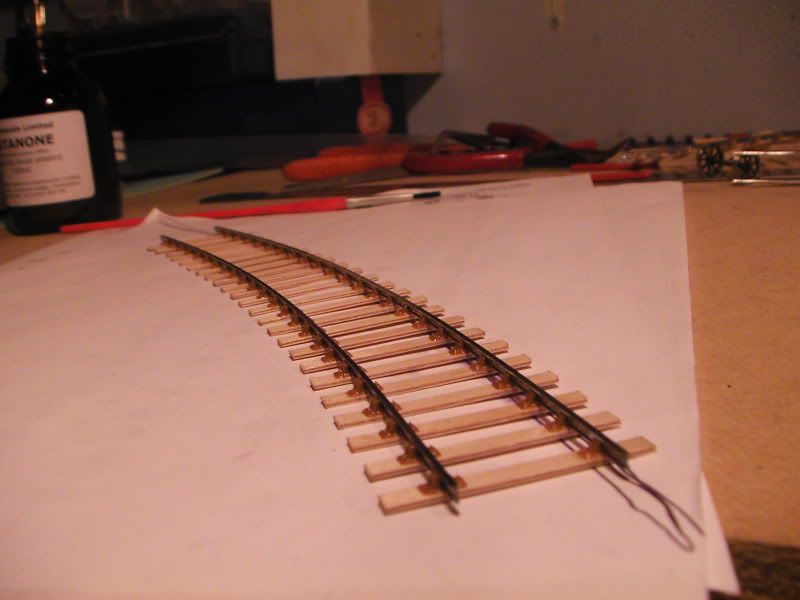

I started by applying Butanone glue to the bottom right chair and moved it along using the triangular gauge and the '+1' roller gauge, poking sleepers and chairs into place and gluing along the way, about 1/3 along I gauged and glued the far bottom left chair and then jumped a few at a time becasue the triangular gauge gauges a few at a time whilst widening slightly on the curve. As I was doing this I would move the roller gauge back every now and then to test the alignment, occassionally I got a tight spot but I pulled that out mostly, the gauge still went through but with a bit of tight friction.

I'm wandering if this is acceptable or not? It's still to gauge but not as brilliant yet I rekon it'll be ok.

I am not sure if the curve is a constant 4ft curve, neither am I sure if the whole curve should have had the gauge widening or not. My original plan wasn't a perfect curve but a pass of about 5 or so that were roughly the same, putting the finished curve to the rough plan seems ok so i think it's ok.

I have a question for anyone who might know; is it ok the 'gum up' the rail webs with butanone to lock the chairs in place to stop them skating about? It seems to work but I don't know if this is what you are supposed to do or let them slide freely for heat expansion. If this is acceptable what is the best thing to clean the rails with after? Seems like most of it evaporates though.

Warning to all; Ventilate your room and try to keep for face away from the work, Butanone has more of an, err.. 'effect' on me than most other things I've used. ![]()

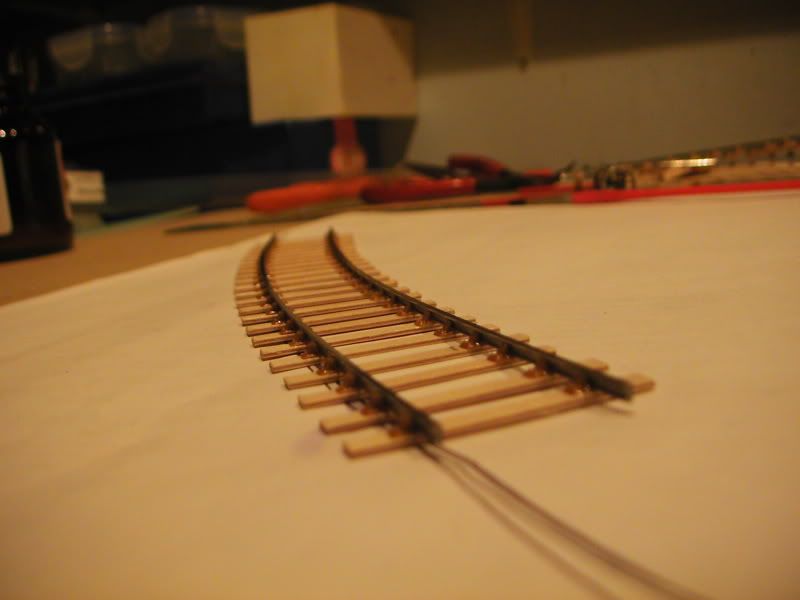

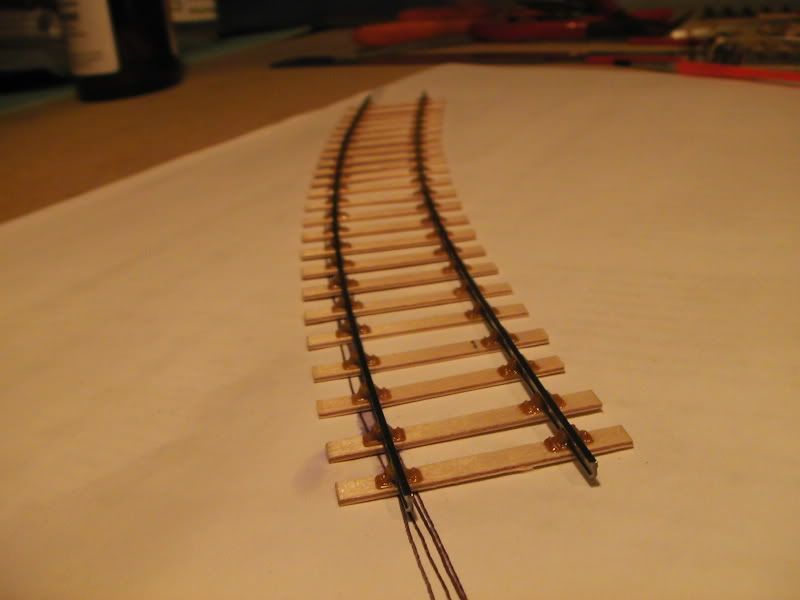

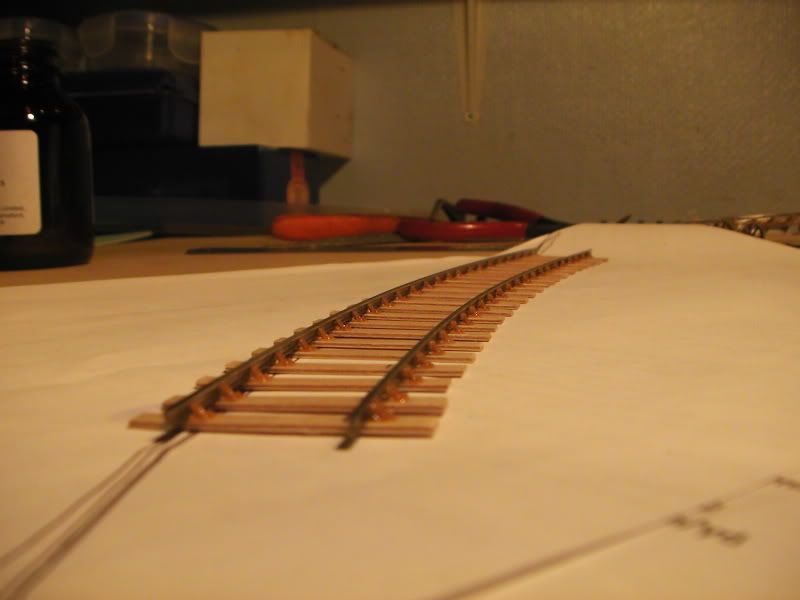

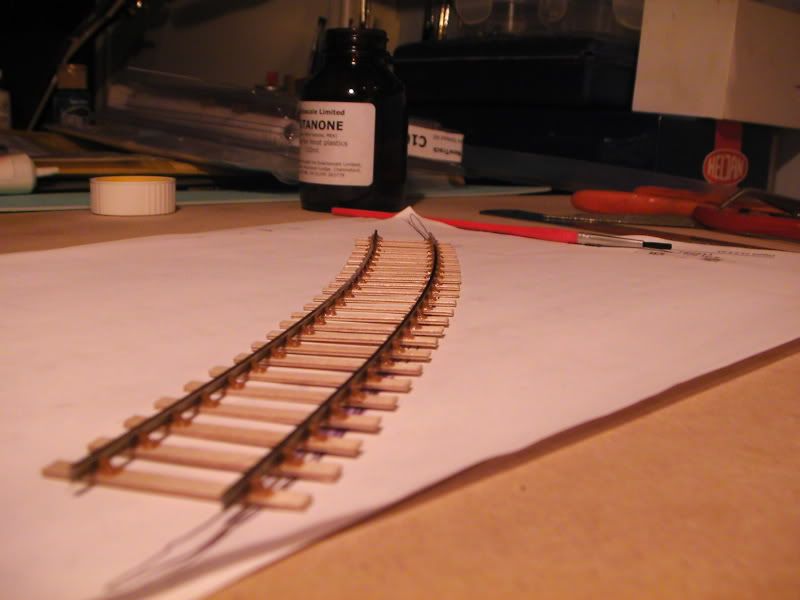

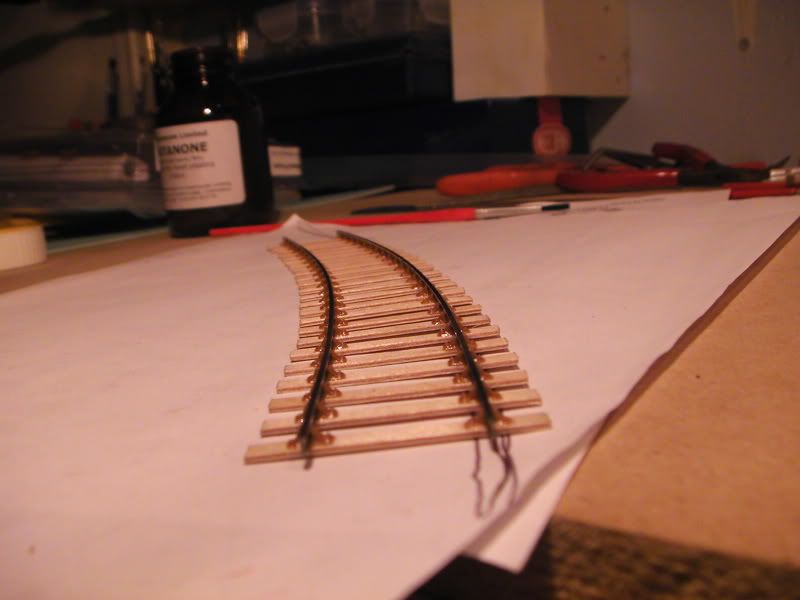

Finished pictures, curve flow seems constant and flowing.

Any advice? ![]()

Despite the things I'm unsure on, I 'think' this is a success at least.

Piccies:

![]() ?

?

-

3

3

12 Comments

Recommended Comments

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now