Ian Fisher

-

Posts

1,333 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Exhibition Layout Details

Store

Posts posted by Ian Fisher

-

-

I could be interested, i see these units daily and have always liked them, but I'd really rather see finished and liveried bodyshells to see how they turned out. what would the options be for motorising? would the underframe components be modelled too? have you got a ballpark cost in mind?

Hi Gordon,

The bodyshells are to be one piece with a lot of the floor to be cast as one with a few bits then to be added. as for motorising you would have a good range of possibilities.

The inside of the shell not being visible!

As for cost it would be dependent on how well and how many bodies come out of the mould really, I don't intend to do 1000's or at a true commercial level really.

-

Getting there, but Why not post some pictures in this thread? Rather than a link.

Did you actually finish it? The thread seems to end abruptly mid way through, and whilst it looks superb, I'd be most inspired by a finished product.

Thanks again for your interest, I understand an N gauge model is due soon....

The thread did end abruptly as I lost my partner of sixteen years to cancer, I am just still getting going again in many ways...

-

1

1

-

-

Ta njee20 for the very positive feedback.

A link was added in the original post

As for cost I've literally a few options I'm not looking at rivalling any more mainstream cottage industry I'm looking at getting body shells available to people

Some photos would be good too - I did happen to find that thread the other day, but looking through the last few pictures there were no photos of a finished product.

I model N, so sadly not a prospective buyer - but you need to help your customers at least a bit! Rough cost, are these a scratch aid or a fully finished kit? One piece body shells or sides? Are you proposing to provide pantographs and bogies and everything?

Your thread title could be better too. It reads like Resin 325 are a vendor. I'd go for something like "OO Gauge 325 EMU kit".

-

With a few more years under this project than I would of liked I am now at a stage of maybe looking at offering these as a kit, I think the bodyshells are to a good to high standard.

More details of a development can be found in my thread 325 in EM 4mm

I am very near completing a set bodyshells for sinking into some RTV.

Any thoughts views feelings, I would love to hear them...

Ian

-

2

2

-

-

Only run on low power when testing with a single servo connected. The lower the voltage the more current the Megapoints will draw. With all the twelve servos moving at startup they will take about 10A at 5V, which equates to 4A or so at 12V. If you do not have sufficient power available (either current or voltage) the servos will never get to their start position and maximum available power will be drawn constantly which is not a good thing. This is one of those scenarios where restricting the power is likely to cause harm rather than be protective.

It would seem that this was part of our issue.

We have a supply that runs 3A at 12v variable...

Tonight have been able to reset a board and finally add in a number of servos away from the layout once again and go back to ones we want in turn to zero them and then do a hi low, I think we may have been in a rush to get stuff further along than we were able.

We then maybe got ahead of ourselves in installing a board full at a lower amp than we shouldve which then gave us further issues.

I think we have turned a corner!

-

When you say 'turned down', I presume you mean the voltage?

Usually it is not the voltage that is inadequate, it is the current that can be drawn from the supply.

Servos can take quite a bit of current each, especially when driving a load. To minimise build up of the effect, it is critical that the servo endstops are set so that it is not continually trying to drive against an immovable object at each end. You will soon know if this is the case because the servo will seem to 'buzz'.

One way round it is to disable the pulse drive after the servo has moved to its new position, but this requires the servo controller to have that facility. I don't know if the Megapoints driver has that capability. On some (e.g. MERG Servo4), it is an option you can select.

Hi Gordon,

Yes I did mean the voltage and yes we have had buzzing too. We are again following a lead from Dave and will see how this will work.

away from the layout things are ok do the same sequence on the layout erm.

Are we ok to just centre the servos manually or do we have to do this off the layout?

We want this to work!

-

Thanks for all the replies so far,

We get how good the system is and have had feedback from Dave too.

I was am interested in seeing what others have and are doing with the system.

The low power thing could be something too in an attempt to safe guard the system at first we were running slightly turned down ( we have a test unit from Maplins which has a slide setting providing a range of settings.)

-

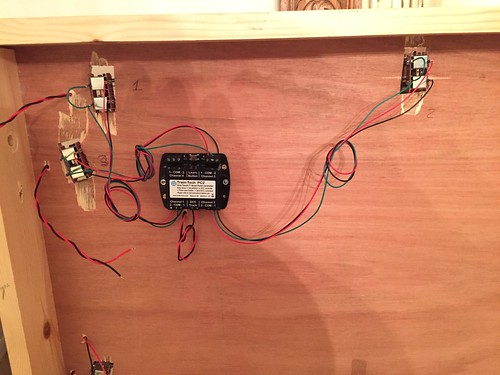

Just getting my head round a first install with this fine system.

We had a few sessions of installing them adding a few points in, then tonight we went for twelve, we then starting having a few servos buzz and then the system would seemingly shut down after nineteen seconds or so.

We then started taking leads out to see what if any connections might of been ropey.

Have we gone west someway?

ideas gratefully received

Ian

-

(To be read in the voice of Monty Burns): Excellent!

These are to fit onto the Bachmann 150s if I remember?

Will have to keep an eye out for these then.

Wild Boar Fell

Hi WBF,

They I'm sure could be made to fit a Bachmann 150 but I haven't tried. that was the other lad who did them!

I have been trying a few ideas for the finer detail on my 325's with many hours of pondering possible routes, but the big part the bodyshells are done and have been done for over a year now just plucking up the courage to finally sink them and create some moulds.

Thanks for the interest

Ian

-

1

1

-

-

Fortunately Mick, I managed to get the DVT when Hornby had it in their 'Last Chance to Buy' sales (Albeit an impulse purchase after seeing a great photo of it at WBQ in BigJim's blog). I have actually seen this set a few times, at least once on Stockport Viaduct on my way back from the Midlands, also last summer I saw the set in Bank Quay (with an EWS 67) when I was heading out to meet a Chirk based company. The set to me does look very smart indeed (if only the loco had some branding too).

Some photos of South & South Mid, yep the lighting is awful.

The large gap in the boards is due to them not currently being sat at the same height.

Other modellable common trains into Bank Quay (apologies if I miss any);

390 - Hornby

350 - Bachmann (not for much longer)

221 - Bachmann

220 - Bachmann

158 - Bachmann (old & new)

156 - Hornby

150 - Bachmann

Windhoff MPV - Bachmann

319 - Bratchell Models

Shame no one does a 325 kit.

Wild Boar Fell

As for a 325 I have most of the bodies almost ready for casting.....

Regards

Ian

-

2

2

-

-

Hello everyone, last night I got the a Parcel from hattons with the last point motors I need plus a train tech accessory decoder. All fitted but need to save some more money's for the accessory decoder £128 worth! Here are a few pictures of progress!

Untitled by blowingoff, on Flickr

Untitled by blowingoff, on Flickr

Untitled by blowingoff, on Flickr

hmmmmm..I wonder if there is any progress to report?

Ian

-

1

1

-

-

Great post Budgie.....what wouldn't we all want eh?

a company announce their intention to produce a new model and they get a load of diverse replies, then we wonder why some companies don't communicate at all.

I don't want a DMU. I just wish someone would make an Electrostar.

-

A few more details have been added to the bodies.

I feel that the blue oxygen door open sensors are probably easier added as part of the body....

a little bit of scribing and I think it will be getting ready to dunk em in RTV.

-

2

2

-

-

Hardboard and elastic bands! You basically add in additional plugs to the mould thst help support the mould

It also reduces the need for expensive rubber

So the top plug mould the carriage inner could be a batten of 20 mm x 20 mm (cheaper filler product balsa or something )

-

1

1

-

-

Hardboard and elastic bands!

Oh and filler blocks...

-

Hi James,

It seems you just make the mould around something stiff!

I had an idea of how to go about it but the very nice people at Tirantis have offered advice and guidance too

Would be interesting to see how you tackle the mould making process Ian!

I tried resin casting the entire vehicle sides & rooves of my 377 Electrostars but couldn't find a good way of making a large enough rubber mould that didn't sag or change shape - will be interested if you find a way around this, very best of luck!!

-

Some RTV was purchased a few months ago and smaller moulds have been trialed.

Watch this space

-

1

1

-

-

I enquired to them about a few parts for the scotsman tender..

I was asked by a none railway friend whose late father had bought them all, but with a few omissions to se if they could be sourced.

I was told that the whole series was no longer in production!

so if anyone has a tender for 4472... I have a friend who would love to see it made up

-

The latest image on the page shows projects at various stages on Gantt Charts. Project 1 (with what I assume is a picture of steam behind the Gantt chart) and 2 are at tooling. Project 3 at CAD. Project 4-6 have been agreed.

That page wsnt paosted before and looks to have 6 products or more underway eh?

-

The webiste is registered to a Birimgham based design company...so no further clues there....this is a bit like the real ale epxolsion!

-

1

1

-

-

A sensible selling option I think from Bachmann. As long as they are released in numbers that allow people to create if they wish the various foromations they turned up in over the years.

And lets not forget the opportunity if needed of adding possibly detail from Colin Craigs excellent offerings, for those of us who prefer that sort of twist.

-

I am with you Andy, where are these bargain bins? all so often quoted. Don't people realise they are shwoing prejudice and bias even unkowingly making such rash statements?

OHLE is a bread apart and such needs a little more tlc, with few current spec models available more pwer to Bachmann for their 90.

Ian

They'd have probably answered that the 85 wasn't a poor seller (although it may not have been as fast as some other items) as all of the stock moved on to retailers within an acceptable length of time. Some think it must have been a poor seller because of some discounting around November 2012 but this was more a by-product of one retail chain being in need of some readies at that time which skewed the marketplace.

-

Have you all noticed the class 142,153,156 and the very old and poor Dapol ex tooling class 155 has not been available from Hornby for some time in some cases many years, except the class 153 Anglia version they are doing.

the Heljan class 86 was totally wrong if they got that right im sure it would of been very profitable for them. eg minor retool to class 87.

Bachmann class 150 wrong again with the full motor enclosure but being retooled,going up very expensive but not totally corrected.

Hornby 153 possible wrong roof profile and lower bodyside tumblehome.

and again the class 82 west coast dvt Hornby probably perfect except the ic light gey paint shade.

142 old tooling...dusted off as and when...I thought they had been hawking a version recently? ripe for a new tooling by someone though id say...

153 new model...donr to a budget but new all the same

156 reworked old Lima and again I could swear they have been out and about..body almost a silk purse the underframe well

155 ex Dapol tooling flawed in its original research...back to the undeframe of the 156 ah yes a sows ear.

150 suffered from a big lot of chassis but wrong? its how Bachmann chose to do it, maybe the term should be couldve of done it better, shape wise its a 150 to me?

A DVT aint a class 82 pal...if only someone did.

Now back to the proper purpose of the thread I said hello to PC1 in the NRM in 1978, the next time I felt such a aweeeeeee was during a visit to NASA...

I think I too despite not needing one for any layout will be cracking out the credit card and getting a set.

-

2

2

-

-

Bright isn't it, and the box is also the large enough to hold the model when its finished.

Jonathan

Was more the total sum! than the colour but yeah useful to be able to keep things in the bought box as the build goes on!

Jonathan, I congrtaulate you its a great piece of engineeering and modelling.

Ian

Class 37 Photos...

in UK Prototype Discussions (not questions!)

Posted · Edited by Ian Fisher

37714 on GCR

Complete with HTG headboard