-

Posts

184 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Events

Exhibition Layout Details

Store

Posts posted by LCUT_creative

-

-

On 13/05/2020 at 10:30, colin penfold said:

Im not a expert Jakub but I wonder if the greeting card industry has any technologies you could adapt. They do lots of embossing into card and paper.

I think the could be a good start to do research. I would think they do it in a continuous fashion with rollers.

I have a general ideal on how I want make it. Ideally I would like to make from wet pulp in a form so that it has decent thickness. Barrier of entry is currently preventing me from doing much about it as I would need 2 metal plates engraved with the brick pattern to start with. I cannot justify something like that on a process that may not work. May also need heating system to dry the pulp quicker. I'm afraid it would make it cost even more than Redutex.

Best regards

Jakub-

1

1

-

1

1

-

-

It is quite expensive but its an option one of many. I can get brick painted to similar level of detail but it takes me forever. Having something that I can just cut and stick to the building is handy even if its expensive. I appreciate if you need to do a large O gauge building it will get very expensive very quickly. I need to figure out how to press brick texture into paper one day. I may be able to make decent corrugated iron the same way.

Best regards

Jakub-

1

1

-

1

1

-

-

On 07/05/2020 at 11:05, Calidore said:

Hi @LCUT_creative, I hope you’re well. Just a quick suggestion which came to mind while I was placing an order yesterday — have you ever thought about making a sheet of correctly scaled window templates to print out, a la Peco point templates? I realise there’d be a bit of work involved in producing them but it’d be helpful for planning buildings which either use non-rectangular windows, or where the end user wanted to cut down the windows to make smaller ones.

Just a thought!

Adam

Hi Adam,

Thank you for your suggestion. Never though of that! I may have to have a think about it. Usually I am happy to provide extra graphics etc if somebody requests. We were thinking of doing a "CAD" browser application for planning your buildings. That never happened unfortunately.

Best regards

Jakub

-

1

1

-

-

On 06/05/2020 at 13:15, brossard said:

Thanks Jakub, these kits have been a great help for me. I never tried Redutex, maybe I should.

John

Hi John,

Thank you glad they were helpful! Redutex is great, not the cheapest way of doing it but its properly textures and has self adhesive backing. I wrapped few of our buildings with it and found it nice to work with.

Best regards

Jakub -

On 04/05/2020 at 13:25, brossard said:

I thought I would share my signalbox:

It started out as B70-13L. After getting it nearly finished my friend pointed out that the windows are GWR. I was horrified so sent off for some windows that were more like LNER. I found a few pics of brick based LNER boxes and chose details that I like from those (like the veranda and end down pipes).

I need to keep my eyes open for a water catchment barrel and finials.

John

Dear John,

Looking excellent! Don't let anybody discourage you from using wrapping papers. I had a look at your other thread where you showcase what you are building for your layout and everything is looking really good. In fact we have been recommending the Redutex line of textured vinyl wrapping for our customers who weren't confident with painting the brickwork.

Best regards

Jakub-

1

1

-

-

19 minutes ago, Moxy said:

Those signal box interior kits are very timely, I'm working on a small signal box at the moment based on a cut down Airfix kit.

Order placed!

Thank you for your order! Hope you enjoy building it!

-

Just to let everybody know we have updated our 4mm scale signal box interiors to be more in line with what we did for the 7mm scale version.

All instruments and the token machine are now resin 3D printed.

I 00-00 OO gauge small signal box interior

I 00-01 OO gauge medium signal box interior

-

9

9

-

-

15 hours ago, colin penfold said:

I am sorry to hear that. All the best to you and your family Jakub

20 hours ago, 88D said:Sad to see that Lcut have been hit by storm Dennis, both house and business. I’m sure we all wish them well at this time, and that they get back on their feet without too much hardship. All the best.

Hi,

Thank you very much to both of you. We are getting there slowly. A lot of the smaller products that were destroyed are back in stock now. New machine is in place and we are slowly returning back to normal.

That engine shed is looking ace. Yellow brick is something I still struggle with and you did it perfectly.

On 13/02/2020 at 20:02, Mallard60022 said:Here are three pics to show the few adaptations so far. This is 4mm by the way.

The left door will be bricked up and a lean to whatever it was and pipework added.

The left door will be bricked up and a lean to whatever it was and pipework added.

This side will actually be removed/adapted and a platform fabricated. I wont have to bother too much as this area was covered and out of any site at all.

The windows have been filled in, bar 1, as in the prototype, using L Cut Arch fillers. The lovely little store shed was made for me By Stubby 47 of the parish.

Fortunately I have quite a few pictures of most sides and the west, entrance end of this building from which I can take reference.

Enough now, but just showing the brilliant adaptability of the L Cut system.

-

4

4

-

-

On 13/02/2020 at 17:00, brossard said:

I thought I'd share my efforts at a couple of buildings. These have been languishing for quite some time as I got on with other things.

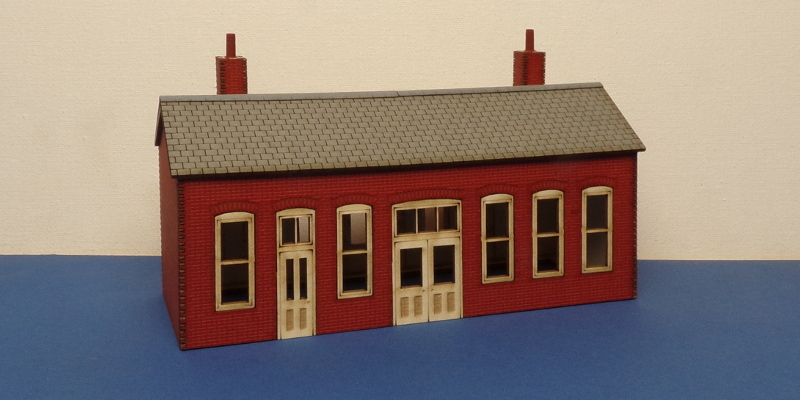

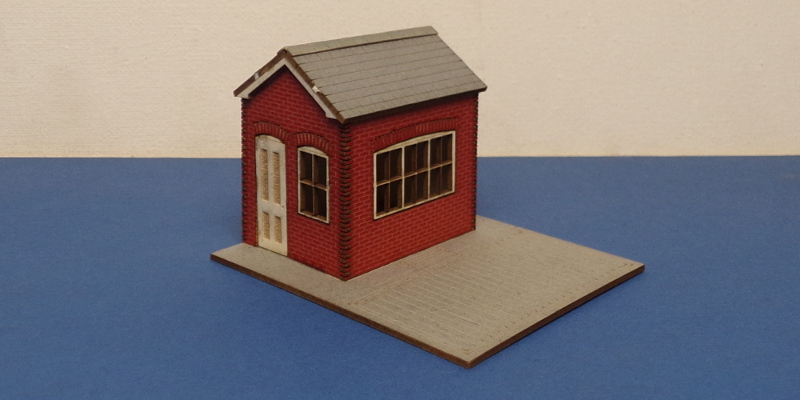

Single road engine shed (B 70-01):

My modifications are extensive. Firstly, I doubt I can make a decent job of painting the bricks and mortar lines so I opted to use Scalescenes brick paper. Joins are hidden by fudges like corner pillars.

I like the Scalescenes method of roofing using overlapping slate paper strips on a template. Tedious but a good effect I think.

Interior is faced with SS white brick paper.

Downspout hoppers are from ModelU. I used brass tube and wire and some plastic strip to complete.

Next the Country Station (B 70-04):

Much the same techniques as the shed. I did do an interior using, you guessed it, elements from SS kits. However, I don't do lights so the interior is just a murky impression.

Let me just add that Lcut kits are a very valuable addition to the modellers toolbox. Well executed and great value. There will be a lot on my layout.

John

Hi John,

Looking really nice! Nothing wrong with using wrapping papers! We sometimes also recommend the Redutex wrapping materials for those who prefer it.

Best regards

Jakub -

On 21/01/2020 at 21:55, Calidore said:

I feel I must add to the positive feedback already much in evidence for LCUT on here. I’ve ordered from Jakub a few times now and can always rely on a single working day for processing time and then delivery on the following day. The QC is perfect with every item arriving crisply cut and well packed — this really is the standard for small suppliers to aspire to and it’s the kind of service which wins repeat business by being so reliable. Big thumbs up!

Adam

Thank you Adam! I am really happy to hear you were happy with the service and parts. As always if there is anything you need from us do not hesitate to get in touch.

Jakub

-

1

1

-

-

Introducing new "My First Layout" kit - station

Continuing to expand our range of "My First Layout" kits we are delighted to introduce a new small railway station. My First Layout kits are designed for the younger and new to modelling offering an easy to assemble, pre coloured kit that will be a great addition to anybody's train set.

Click here to see J 00-01 station on our website

-

7

7

-

-

Introducing new LNER footbridge in OO gauge

After few delays we are happy to announce the LNER footbridge in OO gauge is now ready. Based on the Long Melford in Suffolk in the Eastern region. With this release we now cover footbridges for all of the Big Four in OO gauge.

-

2

2

-

1

1

-

1

1

-

-

Introducing new O gauge signal box

We are delighted to announce we are releasing a new signal box in O gauge. The SR signal box is based on the recently demolished Wool signal box features new details such as finer railings and 3D printed door knobs. This signal box will be available in OO gauge scale in coming months.

-

5

5

-

-

We are delighted to announce we are now able to accept orders and payments over the phone. Our phone number is 01746 716 384. Best times to call are Mon-Thu 10AM-4PM and Fri 9AM-10AM and 2PM-4PM.

-

Following the success our new kit designed for younger modellers we will be continuing our partnership with Warner Shows to bring the kit to the London and Peterborough shows. Free to those who purchase advanced children ticket.

Thank you to Warner Shows and all of the visitors for making a great show!

We will be releasing more kits designed for children in the coming months.

-

4

4

-

2

2

-

-

Introducing new LNER signal box in O gauge

New LNER signal box is now available in O gauge based on the High Dyke signal box. As are all our O gauge signal boxes it is available with stairs either on the left or right side.

http://lcut.co.uk/index.php?product=B%2070-26L&title=B%2070-26L

http://lcut.co.uk/index.php?product=B%2070-26R&title=B%2070-26R

-

2

2

-

-

Dear L-cut creative

I love your stuff and I just enjoyed the build of a 7mm midland signal box. Parts are fitting very well, I pre-painted window frames and all wooden panels for the corners etc . I painted also the inside (upstairs), as a signal box needs to show a little what is inside... I reinforced the corners in invisible places by using triangular balsa profiles. There is only one point where I am not happy with - the distance between steps. Look at the stairs in the picture in post #282. 6 steps for a height of approximately 2 metres. If you look at pictures of the real thing you will notice that there are 10 or 11 steps. How I worked around is to use the card from the roof variant (which has the same thickness as the stairs) and made steps in-between. I would also use a slightly thinner card for the stairs as the thickness used now corresponds with a little more than 5cm or 2" So my suggestion is to re-think the stairs a little. As I am currently not at home I cannot link a picture of my build but will do that in the evening.

all the best

Vecchio

Dear Vecchio,

That is absolutely wonderfully done!

Thank you for the feedback on the steps. There is something I can do about it. I have material that is 1mm thick as opposed to 1.4mm. We use it for the O gauge platform paving.

I cannot promise we will be able to rework the staircase any time soon but I will see what I can do.

Lastly its not been published yet but we have the LNER signal box coming to O gauge in next few days (if all goes well today). We have started to produce some 3D printed finals for it and they will also fit the MR signal box. We will be repacking the MR signal boxes to include them as an option as soon as have time to do it.

Would you like to receive some for your MR signal box? If you get in touch with me at contact@lcut.co.uk I will send you some.

Best regards

Jakub

LCUT creative

-

1

1

-

-

Introducing new LNER signal box in OO gauge

Continuing to expand our signal box range we are introducing an LNER signal box based on the High Dyke signal box. The O gauge version will be launched at the Peterborough show and available for online purchases few days after the show.

http://lcut.co.uk/index.php?product=B%2000-34&title=B%2000-34

-

4

4

-

-

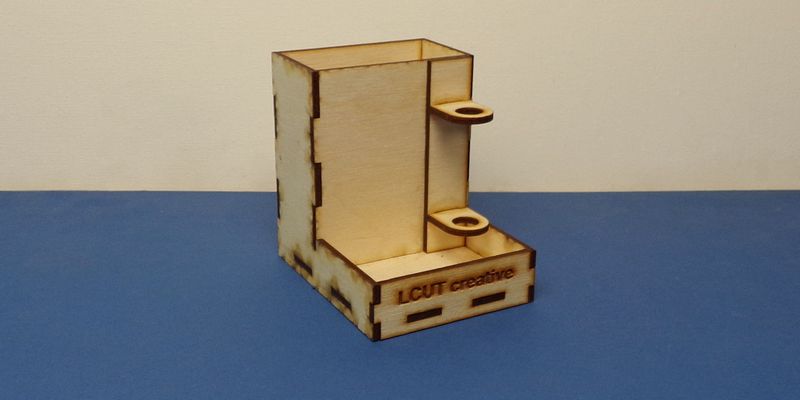

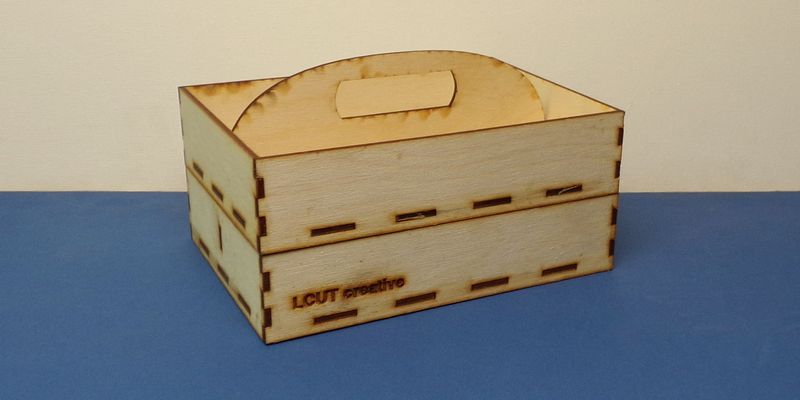

LCUT creative: celebrating 5 years with new line of products

In the month of October 2018 we are celebrating 5 years of producing modular laser cut model railway building kits. To celebrate we will be giving gifts with qualifying orders above £50. The gifts are from the new range of toolboxes and storage units we are releasing at the same time.

To learn more click on this link

The new range of toolboxes and storage units:

http://lcut.co.uk/index.php?product=T%2000-00&title=T%2000-00

http://lcut.co.uk/index.php?product=T%2000-01&title=T%2000-01

http://lcut.co.uk/index.php?product=T%2000-02&title=T%2000-02

http://lcut.co.uk/index.php?product=T%2000-03&title=T%2000-03

-

3

3

-

-

All,

Just wanted to summarize my recent purchase from LCUT. To assist in planning my layout, I wanted to get a couple of the LCUT OO retaining walls and tunnel pieces. To make sure I could correctly pay for my order (via Paypal), I sent Jakub a quick email on 13 August listing what I was anticipating purchasing. Here's the timeline:

13 August - Sent inquire listing kits I was interested in and asking for shipping cost to United States

13 August - Received response from Jakub that listed a very reasonable shipping charge and offer to invoice me via Paypal

14 August - I replied to Jakub saying I wanted to purchase the items and asking him to send an invoice

14 August - Jakub emailed me a Paypal invoice

15 August - I made payment

15 August - Jakub sent an email indicating that he had received payment.

I have to say, fantastic customer service! Even with my little order, Jakub/LCUT immediately answered each of my emails in a friendly way indicating to me that my order was indeed important. Today (23 August) there was a box in my mailbox from LCUT. All arrived in great shape and I can't wait to start these kits so that I can continue my layout planning.

Great job LCUT!

Dave

Dear Dave,

Thank you very much! I am glad I could help you and it arrived safe and sound. Happy Modelling!

Best regards

Jakub

-

2

2

-

-

Introducing new OO gauge signal box

New signal box type is now available in OO gauge. Based on the L&CR/LMS Shap Station signal box in its pre plastered over version.

http://lcut.co.uk/index.php?product=B%2000-33&title=B%2000-33

-

2

2

-

-

Introducing new signal boxes in O gauge

New signal box type is now available in O gauge. Based on the L&CR/LMS Shap Station signal box in its pre plastered over version. It will be coming to OO gauge in next few weeks.

http://lcut.co.uk/index.php?product=B%2070-25R&title=B%2070-25R

http://lcut.co.uk/index.php?product=B%2070-25L&title=B%2070-25L

-

3

3

-

-

We have now launched a new section on website with painting guides. So far I have prepared guides for two different buildings.

I am currently working on a GWR signal box in O gauge. New guide should be published within a week or two.

http://lcut.co.uk/index.php?page=pages/paintingGuides&title=painting%20guides

-

Another heads up for L Cut. On Fridaylast I spent several hours exploring the possibility of using LCut parts for their Island Platform building (and some others) to recreate a version of the Down and Branch Platform Building at Seaton Junction circa 1960 and place an order by the website (so easy to use for me, a digital duffer). I was able to use the excellent parts diagram of the station kit available on the web site and then choose various parts from that as the buildings are quite different in many ways. I was not able to recreate certain features but careful planning had enabled me to order a long list of parts and I believe that will create enough of what I want to see.

My reason for posting is that this was an 'unusual' order for many parts, not a 'kit'. The package arrived yesterday morning. Top rate customer service.

Phil

Hi Phil,

Thank you very much! I am glad everything arrived in timely manner and that you are happy with your order. Happy modelling!

Best regards

Jakub

.jpg.afa191cead1942a0468e32accbb4aaf9.jpg)

LCUT creative

in Smaller Suppliers

Posted

John, I agree. I actually tried making corrugated tin sheets while ago with 3D printed presses and some thin aluminium sheets. In theory it works but it would take so much time to make them I would have to set the prices significantly higher than anybody would be prepared to pay (not only that aluminium sheet is expensive). I would probably have to charge upwards of £10 for a single a4 sheet of corrugated aluminium. Where as with say Slater's making their plastic corrugated sheets, they already have a process and machines for that. Initial cost is still high to get the mold but after that they don't cost them much so they can sell them at good prices. This is why we 3D print all of our plastic parts as the initial cost of that is very low but on the other hand the product cost is higher than if I was to injection mold it. I would need 20+ molds to cover what I have now and that is still growing. The volume I can produce is also significantly lower and my time investment in cleaning and preparing parts is also significant. I can always buy more 3D printers to speed up the production but resin clean up is quite time consuming so that is the limiting factor.

Best regards

Jakub